You’re out of free articles.

Log in

To continue reading, log in to your account.

Create a Free Account

To unlock more free articles, please create a free account.

Sign In or Create an Account.

By continuing, you agree to the Terms of Service and acknowledge our Privacy Policy

Welcome to Heatmap

Thank you for registering with Heatmap. Climate change is one of the greatest challenges of our lives, a force reshaping our economy, our politics, and our culture. We hope to be your trusted, friendly, and insightful guide to that transformation. Please enjoy your free articles. You can check your profile here .

subscribe to get Unlimited access

Offer for a Heatmap News Unlimited Access subscription; please note that your subscription will renew automatically unless you cancel prior to renewal. Cancellation takes effect at the end of your current billing period. We will let you know in advance of any price changes. Taxes may apply. Offer terms are subject to change.

Subscribe to get unlimited Access

Hey, you are out of free articles but you are only a few clicks away from full access. Subscribe below and take advantage of our introductory offer.

subscribe to get Unlimited access

Offer for a Heatmap News Unlimited Access subscription; please note that your subscription will renew automatically unless you cancel prior to renewal. Cancellation takes effect at the end of your current billing period. We will let you know in advance of any price changes. Taxes may apply. Offer terms are subject to change.

Create Your Account

Please Enter Your Password

Forgot your password?

Please enter the email address you use for your account so we can send you a link to reset your password:

People near the site of the disaster say they’re sick. But officials haven’t recognized any link between those symptoms and the fire.

People say they can still taste the metal from the Moss Landing fire. But no one in the local, state, or federal government is able to say why.

The story of Moss Landing got little attention compared to the scale of the disaster. On January 16 — days before Trump reentered office, and as fires continued to burn in and around Los Angeles, when tempers and attention spans were already strained — the Moss Landing Power Plant ignited. We still don’t know what caused the fire, but we do know a few crucial facts: Nearly all of the batteries at the 300 megawatt facility, one of the world’s largest, burned up in the fire, sending a colossal plume of black smoke soaring up from the site for days.

Two months after the blaze was extinguished, many people who live in the vicinity of Moss Landing, a couple hours south of San Francisco, say they’re still sick from the fire. Community organizers on the ground say the number of sick people is in the hundreds, at least. The symptoms range, but there are a few commonalities. Many report having bloody noses in the days immediately following the fire. In the long weeks that followed, they’ve had headaches that don’t respond to pain medications, rashes that resemble burns, and a recurring metallic taste in their mouths. They all say their symptoms go away if they leave their homes and go further away from the site. But the U.S. Environmental Protection Agency and California state regulators have given the all clear.

I have spent weeks trying to get to the bottom of what happened at Moss Landing. I’ve interviewed people who lived in the area and say they’ve experienced breathing issues and other difficulties, many of whom have gathered on Facebook to share photos, stories, and symptoms. Others have offered testimony about these illnesses in public fora and town halls. Multiple lawsuits have been filed against Vistra, the company that runs Moss Landing, over the fire, citing these health issues. Vistra denies the existence of evidence proving pollution from the fire is making people sick, and told me in a statement that the company is “committed to doing everything we can to do right by our community.”

“Moss Landing is not only home to our facility, it’s home to our employees and neighbors,” the statement reads.

And yet, the people say, their symptoms persist. One of the people who told me about their condition is Sheryl Davidson, a former receptionist who lives in the rural nearby town of Prunedale. One of her joys used to be doing Medieval cultural re-enactments, but since the fire she’s been unable to participate.

“My nose just started bleeding. It was traumatic,” she told me. “And I had asthma, but my asthma was miniscule. My whole life, I just had an inhaler. But the inhaler wasn’t working.”

Davidson has other symptoms, including headaches. She says a lump also developed in her face beneath one of her eyes, of which she sent me photos. Despite concerns that something in the air from the fire may have made her sick, she hasn’t left her home, a house she’d lived in since she was a child.

Part of the reason: No one is telling her to leave.

Officials in Monterey County, where Moss Landing is located, acknowledged to me in a statement that they received reports from medical providers that local residents sought care for symptoms related to the battery fire. The EPA said on January 20 that air monitoring throughout the fire incident found no substantial releases of hydrogen fluoride, a fatal pollutant released from battery fires. Records indicate that EPA tested for the particulate matter as well, but there’s no evidence it monitored specifically for heavy metals in the air. Vistra told me it has been doing environmental observations since the incident and is sharing the results with regulators, but said in a statement that it “has not detected risks to public health at this time.”

Davidson may have stayed, but others have left Prunedale, including Brian Roeder, who remembers seeing the fire break out while at home and deciding to leave town with his wife and son out of an abundance of caution. When they got back days later, the fire had been put out. But Roeder told me his wife, who he said is immunocompromised, began reporting breathing issues shortly after they returned. His son started coughing, as well. They quickly left home again, and have been living out of short-term rental apartments far away from the battery plant for weeks.

“This community has been significantly damaged, and they are not coming in to help anybody,” Roeder told me. “There’s been behind the scenes efforts, there’s been some work, but nothing commensurate with the size of this disaster.”

“I know that L.A. caught on fire at the exact same time,” Roeder continued. “That was the huge focus for the state. I know that planes were going down and we had a change in administration. But the fact remains that we, here, cannot explain the absence of support for what is happening from the state. And there’s been a pronounced absence.”

Roeder also started a community organization called Never Again Moss Landing, which has been collecting its own samples of the environment in consultation with a professional lab. In doing so, Roeder became part of a broader effort in the U.S. to create public safeguards for battery storage technology in the wake of Moss Landing. Ground zero for this push is, fittingly, California, where the state Public Utility Commission has responded to the fire by requiring battery storage facility owners to make emergency response plans and adhere to modern fire codes for battery storage.

Some Democratic lawmakers in California want to go further, empowering localities to be the final decisionmakers on whether storage projects get built, as opposed to state regulators.

In some pockets of the U.S., this push for battery safety risks morphing into a threat to the energy transition. For my newsletter, The Fight, I’ve chronicled how towns and counties across the U.S., from New York City to rural Texas, are now banning battery storage, citing the Moss Landing fire and the fear another battery fire could happen in their backyards.

By many metrics, Moss Landing is an outlier. The Moss Landing facility was a giant field of batteries inside a former factory, essentially trapping all these combustible mini-bombs prone to “thermal runaway,” a phenomenon where rising heat from a fire leads to a chain reaction of chemical ignition, inside an insulated box. Concerns about thermal runaway are a reason why almost all battery storage today is installed in storage containers and with an appropriate distance between individual batteries.

But Moss Landing is also a crucial test case for the future of battery storage and public trust.

This morning, the renewables sector took a big stride towards attempting to calm the rage against battery storage. American Clean Power, the leading renewables trade group, released an analysis of 35 battery storage fires in the U.S. from 2012 through the end of last year. Many of the incidents involved “early-generation” battery tech, it said, adding that “improved safety measures, such as advanced thermal management, suppression systems, and containment enclosures, significantly reduc[ed] the likelihood of large-scale incidents.”

The analysis does not speculate as to what may have caused the fire at Moss Landing, simply noting investigations into the incident are ongoing. But at the same time, ACP released a new blueprint for safe battery storage development. In the blueprint, the association acknowledges that some of its recommendations — including a requirement that all battery storage facilities meet a new fire safety standard produced years after Moss Landing was commissioned — are aimed at “holistically addressing concerns generated by the Moss Landing Fire.”

Residents are deeply suspicious of the official assessments denying what, to them, are obvious health impacts. To be candid, I can’t blame them. It strains credulity to imagine a battery fire of this size and scope right next door to you somehow creating no pollution worthy of public concern.

“When you burn [batteries] it moves toxic chemicals into the air,” said Tracey Woodruff, a former EPA senior scientist and policy advisor specializing in chemical contamination of the environment, who now works at the University of California San Francisco. “If this is an uncontrolled burn, you can’t just say there isn’t going to be fallout from that or exposure to the population.”

There’s data making people afraid too. In late January, researchers at San Jose State University alerted the public that they’d discovered “unusually high concentrations of heavy-metal nanoparticles” and a “hundreds- to thousand-fold” increase in nickel, manganese, and cobalt — metals all present in Moss Landing’s batteries — in soil two miles from the power plant in the Elkhorn Slough Reserve, one of the state’s biggest estuaries. Exposure to these metals can cause serious health issues, some of which mirror the symptoms described by residents in the area who are sick.

Exposure to dust with heavy metals can be dangerous at even relatively low levels. A county health advisory shared with local medical professionals in February urged doctors to complete a comprehensive physical of anyone concerned about the impacts of the fire on their health. It noted that breathing or coming into direct skin contact with “heavy metal dusts and other particulate matter from smoke” can result in a metallic taste and difficulty breathing, as well as exacerbate underlying conditions like asthma.

Discovering the metals’ omnipresence in the Slough after the fire led Ivano Aiello, a researcher at SJSU who collected that data, to conclude that the contamination is probably more widespread than is publicly understood.

“I freaked out [after the study] because I was breathing the stuff. I was out there for days and I had no idea,” he told me. “Then I alerted the authorities … and they did their own investigation.”

Subsequent studies conducted by county and state environmental officials, including within the Elkhorn Slough, found no level of these heavy metals that they said could be conclusively tied to the fire. On March 19, farm advisors at the University of California Cooperative Extension undertook a “limited study” that found a “slight deposition of metals (copper and manganese) may have occurred in one agricultural field closest to the battery fire site,” but that the “concentration of metals measured were within normal ranges for all soil types evaluated.” Dole, the giant produce company, which has operations in the area, told me that on its end “no health impacts have been reported and no soil contamination has been detected as a result of the Moss Landing battery fire.”

But Roeder and many other members of the surrounding communities are worried there isn’t enough testing being done to find out whether contaminants entered the atmosphere, especially since air pollution is rarely spread evenly. Like Covid-19, the only way we will ever know the extent of the problem is with more testing, testing, testing.

Roeder is trying to do this work himself. On what he says is his own dime, he and other members of Never Again Moss Landing have collected dust samples across the region in consultation with a credentialed lab in the state, BioMax, which he told me reached out after the fire.

On Wednesday, a local NBC affiliate reported that Don Smith, a toxicologist at the University of California San Diego, confirmed elevated levels of nickel, cobalt, and manganese in the dust samples collected by Never Again Moss Landing. “There is reason to be concerned,” Smith told the TV station, adding that people living near the plant should wear masks regularly if they’re interacting with dust in their homes and be careful not to disturb soil in their yards. “Both manganese and, to a lesser extent, cobalt are known to be neurotoxins. And nickel, of course, is recognized as a carcinogen.”

Frustratingly, though, there is no solid proof to date of a conclusive link between the illnesses and metal exposure — just a lot of people with symptoms, a study that hasn’t been replicated in other pieces of research, and samples collected by residents who are also involved in litigation against the company. Still, that’s a lot of evidence of a problem. Medical mysteries are also common in environmental catastrophes like the Flint water crisis and the infamous DuPont PFOA debacle in Parkersburg, West Virginia, in which obviously sick residents butted heads with regulators for years, demanding information and testing.

What’s next for Moss Landing? The three counties most impacted — Monterey, Santa Cruz, and San Benito — just concluded a community health survey that solicited comments from potentially impacted residents and received more than 1,500 responses, according to figures I reviewed that were shared at a recent Monterey County public meeting. When that study is out, we’ll have a comprehensive view of the locations where the sick live to see where it lines up with the plume that emitted from Moss Landing.

Taking a wider view, any society that’s going to rely primarily on intermittent energy sources like solar and wind needs battery storage to keep the lights on. That will require winning the public’s trust in battery technology. The Moss Landing fire was bad, and over time risks becoming an East Palestine moment for the energy transition. But the lack of a loud, sizable government response to calm the nerves of people publicly claiming illness is likely to be even more damaging to the future of the battery sector.

Log in

To continue reading, log in to your account.

Create a Free Account

To unlock more free articles, please create a free account.

Wildfires are moving east.

There were 77,850 wildfires in the United States in 2025, and nearly half of those — 49% — ignited east of the Mississippi River, according to statistics released last week by the National Interagency Fire Center. That might come as a surprise to some in the West, who tend to believe they hold the monopoly on conflagrations (along with earthquakes, tsunamis, and megalomaniac tech billionaires).

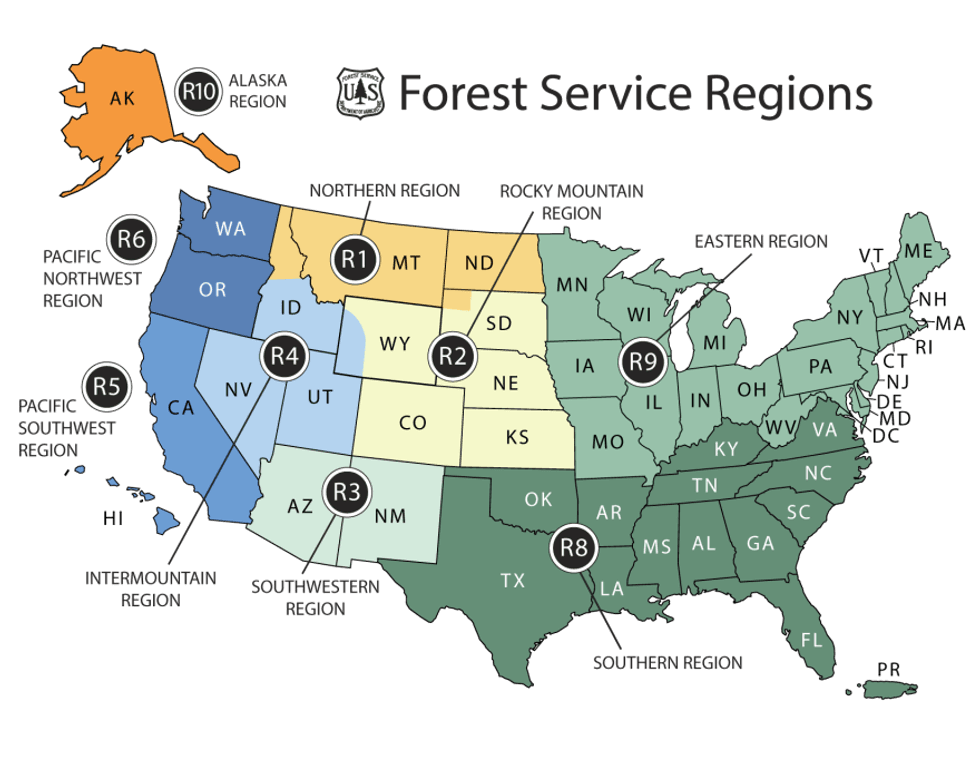

But if you lump the Central Plains and Midwest states of Minnesota, Iowa, Missouri, Arkansas, Oklahoma, and Texas along with everything to their east — the swath of the nation collectively designated as the Eastern and Southern Regions by the U.S. Forest Service — the wildfires in the area made up more than two-thirds of total ignitions last year.

Like fires in the West, wildfires in the eastern and southeastern U.S. are increasing. Over the past 40 years, the region has seen a 10-fold jump in the frequency of large burns. (Many risk factors contribute to wildfires, including but not limited to climate change.)

What’s exciting to wildfire researchers and managers, though, is the idea that they could catch changes to the Eastern fire regime early, before the situation spirals into a feedback loop or results in a major tragedy. “We have the opportunity to get ahead of the wildfire problem in the East and to learn some of the lessons that we see in the West,” Donovan said.

Now that effort has an organizing body: the Eastern Fire Network. Headed by Erica Smithwick, a professor in Penn State’s geography department, the research group formed late last year with the help of a $1.7 million, three-year grant from the Gordon and Betty Moore Foundation, a partner with the U.S. National Science Foundation, with the goal of creating an informed research agenda for studying fire in the East. “It was a very easy thing to have people buy into because the research questions are still wide open here,” Smithwick told me.

Though the Eastern U.S. is finally exiting a three-week block of sub-freezing temperatures, the hot, dry days of summer are still far from most people’s minds. But the wildland-urban interface — that is, the high-fire-risk communities that abut tracts of undeveloped land — is more extensive in the East than in the West, with up to 72% of the land in some states qualifying as WUI. The region is also much more densely populated, meaning practically every wildfire that ignites has the potential to threaten human property and life.

It’s this density combined with the prevalent WUI that most significantly distinguishes Eastern fires from those in the comparatively rural West. One fire manager warned Smithwick that a worst-case-scenario wildfire could run across the entirety of New Jersey, the most populous state in the nation, in just 48 hours.

Generally speaking, though, wildfires in the East are much smaller than those in the West. The last megafire in the Forest Service’s Southern Region was as far west in its boundaries as you can get: the 2024 Smokehouse Creek fire in Texas and Oklahoma, which burned more than a million acres. The Eastern Region hasn’t had a megafire exceeding 100,000 acres in the modern era. For research purposes, a “large” wildfire in the East is typically defined as being 200 hectares or more in size, the equivalent of about 280 football fields; in the West, a “large” wildfire is twice that, 400 hectares or more.

But what the eastern half of the country lacks in total acres burned (for that statistic, Alaska edges out the Southern Region), it makes up for in the total number of reported ignitions. In 2025, for example, the state of Maine alone recorded 250 fires in August, more than doubling its previous record of just over 100 fires. “The East is highly fragmented,” Donovan, who is contributing to the Eastern Fire Network’s research, told me. “We have a lot of development here compared to the West, and so it’s much more challenging for fires to spread.”

Fires in the West tend to be long-duration events, burning for weeks or even months; fires in the East are often contained within 48 hours. In New Jersey, for example, “smaller, fragmented forests, which are broken up by numerous roads and the built environment, [allow] firefighters to move ahead of a wildfire to improve firebreaks and begin backfiring operations to help slow the forward progression,” a spokesperson for the New Jersey Forest Fire Service told me.

The parcelized nature of the eastern states is also reflected in who is responding to the fires. It is more common for state agencies and local departments — including many volunteer firefighting departments — to be the ones on the scene, Debbie Miley, the executive director of the National Wildfire Suppression Association, a trade group representing private wildland fire service contractors, told me by email. On the one hand, the local response makes sense; smaller fires require smaller teams to fight them. But the lack of a joint effort, even within a single state, means broader takeaways about mitigation and adaptation can be lost.

“Many eastern states have strong state forestry agencies and local departments that handle wildfire as part of an ‘all hazards’ portfolio,” Miley said. “In the West, there’s often a deeper bench of personnel and systems oriented around long-duration wildfire campaigns (though that varies by state).”

All of this feeds into why Smithwick believes the Eastern Fire Network is necessary: because of this “intermingling, at a very fine scale, of different jurisdictional boundaries,” conversations about fire management and the changing regimes in the region happen in parallel, rather than with meaningful coordination. Even within a single state, fire management might be divided between different agencies — such as the Game Commission and the Bureau of Forestry, which share fire management responsibilities in Pennsylvania. Fighting fires also often involves working with private landowners in the East; in the West, on the other hand, roughly two-thirds of wildfires burn on public land, which a single agency — e.g. the Bureau of Land Management, Forest Service, or Park Service — manages.

But “wildfire risk is going to be different than in the West, and maybe more variable,” Smithwick told me. Identifying the appropriate research questions about that risk is one of the most important objectives of the Eastern Fire Network.

Bad wildfires are the result of fuel and weather conditions aligning. “We generally know what the fuels are [in the East] and how well they burn,” Smithwick said. But weather conditions and their variability are a greater question mark.

Nationally, fire and emergency managers rely on indices to predict fire-weather risk based on humidity, temperature, and wind. But while those indices are dialed in for the Western states, they’re less well understood in the East. “We hope to look at case studies of recent fires that have occurred in the 2024 and 2025 window to look at the antecedent conditions and to use those as case studies for better understanding the mechanisms that led to that wildfire,” Smithwick said.

Learning more about the climatological mechanisms driving dry spells in the region is another explicit goal. Knowing how dry spells evolve, and where, will help researchers and eventually policymakers to identify mitigation strategies for locations most at risk. Smithwick also expects to learn that some areas might not be at high risk: “We can tell you that this is not something your community needs to invest in right now,” she told me.

Different management practices, jurisdictions, terrains, and fuel types mean solutions in the East will look different from those in the West, too. As Donovan’s research has found, the unmanaged regrowth of forests in the northeast in particular after centuries of deforestation has led to an increase in trees and shrubs that are prone to wildfires. Due to the smaller forest tracts in the area, mechanical thinning is a more realistic solution in eastern forests than on large, sprawling, remote western lands.

Prescribed burns tend to be more common and more readily accepted practices in the East, too. Florida leads the nation in preventative fires, and the New Jersey Forest Fire Service aims to treat 25,000 acres of forest, grasslands, and marshlands with prescribed fire annually.

The winter storms that swept across the Eastern and Southern regions of the United States last month have the potential to queue up a bad fire season once the land starts to thaw and eventually dry out. Though the picture in the Eastern Region is still coming into focus depending on what happens this spring, in the Southern region the storms have created “potential compaction of the abundant grasses across the Plains, in addition to ice damage in pine-dominant areas farther east,” the National Interagency Fire Center wrote in last Monday’s update to its nationwide fire outlook. (The nearly million-acre Pinelands of New Jersey are similarly a fire-adapted ecosystem and are “comparable in volatility to the chaparral shrublands found in California and southern Oregon,” the spokesperson told me.)

The compaction of grasses is significant because, although they will take longer to dry and become a fuel source, it will ultimately leave the Southern region covered with a dense, flammable fuel when summer is in full swing. Beyond the Plains, in the Southeast’s pine forests, the winter-damaged trees could cast “abundant” pine needles and “other fine debris” that could dry out and become flammable as soon as a few weeks from now. “Increased debris burning will also amplify ignitions and potential escapes, enhancing significant fire potential during warmer and drier weather that will return in short order,” NIFC goes on to warn.

Though the historically wet Northeast and humid Southeast seem like unlikely places to worry about large wildfires, as conditions change, nothing is certain. “If we learned anything from fire science over the past few decades, it’s that anywhere can burn under the right conditions,” Smithwick said. “We are burning in the tundra; we are burning in Canada; we are burning in all of these places that may not have been used to extreme wildfire situations.”

“These fires could have a large economic and social cost,” Smithwick added, “and we have not prepared for them.”

New guidelines for the clean fuel tax credit reward sustainable agriculture practices — but could lead to greater emissions anyway.

The Treasury Department published proposed guidance last week for claiming the clean fuel tax credit — one of the few energy subsidies that was expanded, rather than diminished, by Trump’s One Big Beautiful Bill Act. There was little of note in the proposal, since many of the higher-stakes climate-related decisions about the tax credit were made by Congress in the statute itself. But it did clear up one point of uncertainty: The guidance indicates that the administration will reward biofuel crops cultivated using “climate-smart agriculture” practices.

On the one hand, it’s a somewhat surprising development simply because of Trump’s record of cutting anything with climate in the title. Last April, the U.S. Department of Agriculture terminated grants from a Biden-era “Climate-Smart Commodities” program, calling it a “slush fund,” and refashioned it into the “Advancing Markets for Producers” initiative.

On the other hand, depending on how the Trump administration implements it, integrating climate-smart agriculture into the clean fuel tax credit could become its own kind of slush fund, paying out billions in taxpayer dollars for questionable benefits and with little accountability.

The clean fuel tax credit, known by its section of the tax code as 45Z, subsidizes the production of low-carbon transportation fuels for vehicles and aviation. Companies can earn up to $1 per gallon depending on the carbon intensity of the production process.

Sourcing corn and soy from farms that use climate-smart agriculture practices is one potential way for biofuel producers to claim more of the credit. “Climate-smart agriculture” can refer to a wide variety of techniques that increase the amount of soil stored in carbon or otherwise reduce emissions, such as reducing soil disturbance, planting cover crops, or implementing nutrient management practices that reduce nitrous oxide emissions. But to date, the federal government has not issued guidance for how to account for these practices.

The Biden administration put out proposed rules just before leaving office that were quite controversial, Nikita Pavlenko, the fuels and aviation program director at the International Council on Clean Transportation, told me. The methodology relied entirely on modeling and did not require farmers to take any real-life measurements of soil carbon before or after adopting the climate-smart practice. The rules also assume that these climate-smart practices would be implemented anew, when in reality many farms have been practicing some of them for years without subsidies. That means ethanol producers could potentially get free money to buy corn from farms that adopted no-till practices long ago, with no additional benefit for the climate.

“These climate-smart ag practices are a rare example of bipartisanship, for what it’s worth, and there’s a lot of money to be made in it,” Pavlenko told me. “But I’m not sure exactly how much actual greenhouse gas reduction or sequestration.”

According to estimates by Pavlenko’s group, the lack of an additionality requirement could lead to the government paying $2.1 billion in subsidies for farms to keep doing what they were already doing, with no new benefits for the climate.

I should note that the climate integrity of the clean fuel tax credit, also known as 45Z, was already compromised by changes made in the OBBBA. Subsidies for crop-based biofuels can indirectly drive deforestation. Prior to Trump’s tax law, producers would have had to take into account emissions related to land use changes when they calculated the carbon intensity of their fuel. Now they don’t. The change will make it much easier for a fuel like ethanol, which is already heavily subsidized through other programs, to qualify.

That, in turn, could cost taxpayers an estimated five times as much per year. When the subsidy was first created in the Inflation Reduction Act, the Joint Committee on Taxation estimated that it would cost taxpayers $2.9 billion over three years. After the OBBBA passed, extending the credit by two years, the committee’s estimate was $25.7 billion.

The existing proposal for incorporating climate-smart agriculture practices into the tax credit calculation would likely push that estimate even higher. After the Biden administration released its proposal last January, groups like Pavlenko’s submitted comments critiquing the methods and suggesting changes. But after the Trump administration took over, it was unclear what would happen with it, he said.

Last week’s guidance was still somewhat vague about what’s next for the climate-smart agriculture calculations, saying only that the proposal published in January is still “undergoing testing, peer review, and public comment,” and that the Treasury expects it to be ready some time in 2026. In the meantime, the Treasury will be taking public comments on the broader 45Z guidance through April 6 and hold a public hearing on May 28.

On Tesla’s sunny picture, Chinese nuclear, and Bad Bunny’s electric halftime show

Current conditions: The Seattle Seahawks returned home to a classically rainy, overcast city from their win in last night’s Super Bowl, though the sun is expected to come out for Wednesday's victory parade • Severe Tropical Cyclone Mitchell is pummeling Western Australia with as much as 8 inches of rain • Flash floods from Storm Marta have killed at least four in Morocco.

Orsted’s two major offshore wind projects in the United States are back on track to be completed on schedule, its chief executive said. Rasmus Errboe told the Financial Times that the Revolution Wind and Sunrise Wind projects in New England would come online in the latter half of this year and in 2027, respectively. “We are fully back to work and construction on both projects is moving forward according to plan,” Errboe said. The U.S. has lost upward of $34 billion worth of clean energy projects since President Donald Trump returned to office, as I wrote last week. A new bipartisan bill introduced in the House last week to reform the federal permitting process would bar the White House from yanking back already granted permits. For now, however, the Trump administration has signaled its plans to appeal federal courts’ decisions to rule against its actions to halt construction on offshore turbines.

The fight over the billions in federal funding the White House is holding up for the Gateway rail project between New Jersey and New York, meanwhile, heated up over the weekend. On Friday night, a federal judge ordered the Trump administration to unfreeze the nearly $16 billion to the project, just hours after construction ground to a halt as funding ran dry. In her ruling, U.S. District Judge Jeannette Vargas of the Southern District of New York wrote that “plaintiffs have adequately shown that the public interest would be harmed by a delay in a critical infrastructure project.” Trump had his own idea in mind. Over the weekend, the White House proposed releasing the money only if Senate Minority Leader Chuck Schumer of New York agreed to rename Penn Station after Trump.

Tesla has started hiring staff to ramp up production of solar panels as the company looks to build 100 gigawatts of panel-manufacturing capacity supplied with raw materials produced in America. In a job posting on LinkedIn, Seth Winger, Tesla’s senior manager for solar products engineering, wrote that the panel-producing buildout was “an audacious, ambitious project.” For that, he wrote, “we need audacious, ambitious engineers and scientists to help us grow to massive scale. If you want to solve tough manufacturing problems at breakneck speed and help the U.S. breakthrough on renewable energy generation, come join us.” One of the listings indicated that the target date for bringing the new factories online was the “end of 2028,” giving an indication of timing that Reuters noted had been previously absent from Elon Musk’s public statements. Bloomberg reported last week that Tesla is already looking at sites in New York, Arizona, and Idaho for its manufacturing expansion.

The Trump administration tried to yank permits from the offshore wind projects off New England on the grounds that the towering turbines caused more ecological destruction than the electricity is worth. On Friday, however, Trump signed a proclamation reopening a giant marine preserve in the Atlantic Ocean to commercial fishing. First established at the end of the Obama administration, the Northeast Canyons and Seamounts Marine National Monument lies 130 miles off the coast of Cape Cod, encompassing what The New York Times described as “an area the size of Connecticut that is home to dolphins, endangered whales, sea turtles, and ancient deep-sea corals.” While Trump lifted the ban on commercial fishing in the zone during his first administration, President Joe Biden reinstated the restrictions. But this isn’t the first time Trump reopened a national marine national monument to fishing. In April, he ended protections for the Pacific Islands Heritage Marine National Monument located 750 miles west of Hawaii and designated by President George W. Bush in 2009.

Sign up to receive Heatmap AM in your inbox every morning:

Connecitcut’s Department of Insurance has launched a website that displays extensive information about the climate risk of every property in the state in what E&E News called “an unprecedented move to alert residents and to promote flood insurance.” The details include each property’s history of damage from floods and other events predicted to get worse as the planet warms. “A single risk score does not fully convey flood and climate risk,” department spokesperson Mary Quinn said. The department plans a marketing campaign this year with ads on radio, TV, and social media, and workshops for insurance agents on how to use the website. Nationwide, climate change is already raising household costs by $900 per year, as Heatmap’s Matthew Zeitlin reported last year. Wildfires have already “destroyed California’s insurance market,” according to an interview with Heatmap's Shift Key podcast last year with an expert at the University of Pennsylvania’s Wharton School.

Unit 1 of the Taipingling nuclear power station in China’s Guangdong has reached criticality seven years after construction began on the gigawatt-sized Hualong One reactor. The debut atom-splitting means the newest reactor is months, if not weeks, from entering into commercial operation. If that enticingly single-digit number of years to build a piece of infrastructure that takes the U.S. more than a decade wasn’t enough of a sign of China’s nuclear strengths, the country this week hit another milestone on a separate atomic station. At the Zhangzhou-3 nuclear reactor, workers last week installed the inner steel dome of the containment building.

Nearly a decade after Puerto Rico’s power grid collapsed and plunged America’s most populous territory into the second-longest blackout in world history, the island’s biggest musical star performed a Super Bowl halftime show that included linemen working on transformers. Bad Bunny’s performance, a revue of his reggaeton hits, served as an ode to what he called “my motherland, my homeland, Puerto Rico.” The grid still suffers regular outages. When it’s working, the power system sends occasional surges through wires that fry appliances. Electricity rates are higher than almost any state, despite Puerto Rico suffering worse poverty rates than Mississippi. At one point, Bad Bunny climbed a utility pole on stage waving a light-blue Puerto Rican flag, a symbol of the movement to establish the island territory as its own independent nation. It was a powerful political statement at America’s most-watched sporting event. For energy nerds, it was a rare opportunity to reflect on one of the worst, most prolonged infrastructure disasters in modern American history.