You’re out of free articles.

Log in

To continue reading, log in to your account.

Create a Free Account

To unlock more free articles, please create a free account.

Sign In or Create an Account.

By continuing, you agree to the Terms of Service and acknowledge our Privacy Policy

Welcome to Heatmap

Thank you for registering with Heatmap. Climate change is one of the greatest challenges of our lives, a force reshaping our economy, our politics, and our culture. We hope to be your trusted, friendly, and insightful guide to that transformation. Please enjoy your free articles. You can check your profile here .

subscribe to get Unlimited access

Offer for a Heatmap News Unlimited Access subscription; please note that your subscription will renew automatically unless you cancel prior to renewal. Cancellation takes effect at the end of your current billing period. We will let you know in advance of any price changes. Taxes may apply. Offer terms are subject to change.

Subscribe to get unlimited Access

Hey, you are out of free articles but you are only a few clicks away from full access. Subscribe below and take advantage of our introductory offer.

subscribe to get Unlimited access

Offer for a Heatmap News Unlimited Access subscription; please note that your subscription will renew automatically unless you cancel prior to renewal. Cancellation takes effect at the end of your current billing period. We will let you know in advance of any price changes. Taxes may apply. Offer terms are subject to change.

Create Your Account

Please Enter Your Password

Forgot your password?

Please enter the email address you use for your account so we can send you a link to reset your password:

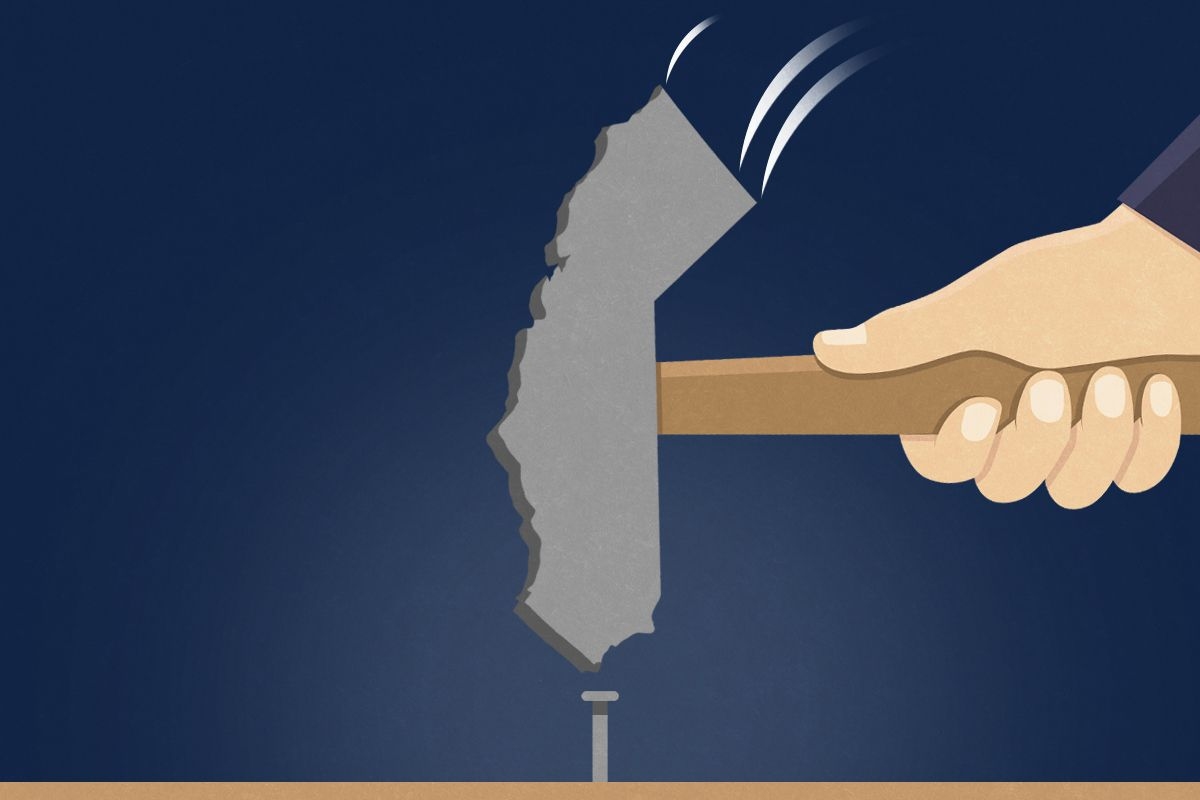

Here’s a grim fact: The most destructive fires in recent American history swept over a state with the country’s strictest wildfire-specific building code, including in some of the neighborhoods that are now largely smoldering rubble.

California’s wildfire building code, Chapter 7A, went into effect in 2008, and it mandates fire-resistant siding, tempered glass, vegetation management, and vents for attics and crawlspaces designed to resist embers and flames. The code is the “most robust” in the nation, Lisa Dale, a lecturer at the Columbia Climate School and a former environmental policy advisor for the State of Colorado, told me. It applies to nearly any newly built structure in one of the zones mapped out by state and local officials as especially prone to fire hazard.

The adoption of 7A followed years of code development and mapping of hazardous areas, largely in response to devastating urban wildfires such as the Tunnel Fire, which claimed more than 3,000 structures and 25 lives in Oakland and Berkeley in 1991, and kicked off renewed efforts to harden Californian homes.

The Federal Emergency Management Agency’s report on the 1991 fire makes for familiar reading as the Palisades and Eaton fires still smolder. The wildland-urban interface, it says, was put at extreme risk by a combination of dry air, little rainfall, hot winds blowing east to west, built-up vegetation that was too close to homes, steep hills, and limited access to municipal water. The report also castigates the “unregulated use of wood shingles as roof and siding material.”

This was not the first time a destructive fire on the wildland-urban interface had been partially attributed to ignitable building materials. The 1961 Bel-Air fire, for instance, which claimed almost 200 homes, including that of Burt Lancaster, and the 1959 Laurel Canyon fire were both, FEMA said, evidence of “the wood roof and separation from natural fuels problems,” as were fires in 1970 and 1980 near where the Tunnel Fire eventually struck in 1970 and 1980.

But it was the sheer scale of the Tunnel Fire that prompted action by California lawmakers.

Throughout the 1990s, fire-resilient roofing requirements were ramped up, designating which materials were allowed in fire hazard areas and throughout the state. By all accounts, the building code works — but only when and where it’s in force. Dale told me that compliant homes were five times as likely to survive a wildfire. Research by economists Judson Boomhower and Patrick Baylis found that the code “reduced average structure loss risk during a wildfire by 16 percentage points, or about a 40% reduction.”

“The challenge from the perspective of wildfire vulnerability is that those codes are relatively recent, and the housing stock turns over really slowly, so we have this enormous stock of already built homes in dangerous places that are going to be out there for decades,” Boomhower told me.

The 7A building code applies only to new buildings, however. In long-settled areas of California like Pacific Palisades, which has little new housing construction or even existing home turnover due to high costs and permitting complications, especially in areas under the jurisdiction of the California Coastal Commission, many houses are not just failing to comply with Chapter 7A, but also with any housing code at all.

Looking at which homes had survived past fires, Steve Quarles, who helped advise the California State Fire Marshal on developing 7A, told me, “What really mattered was if it was built under any building code.” Many homes destroyed by the fires in Los Angeles likely were not. In Pacific Palisades, fire management is a frequent topic of concern and discussion. But as late as 2018, local media in Pacific Palisades noted that the area still had some homes with wood shingle roofs.

While a complete inventory of homes lost in the Palisades and Eaton fires has yet to be taken, the neighborhoods were full of older homes. According to CalFire incident reports, of the almost 47,000 structures in the zone of the Palisades Fire, more than 8,000 were built before 1939, and 44,560 were built before 2009. For the Eaton Fire area, of the around 41,000 structures, almost 14,000 were built before 1939, and only around 1,000 were built since 2010.

A Pacific Palisades home designed by architect Greg Chasen and built in 2024, however, survived the fire and went viral on X after he posted a photo of it still standing after the flames had moved through. The home embodied some of the best practices for fire-safe building, according to Bloomberg, including keeping vegetation away from the building, a metal roof, tempered glass, and fire-resistant siding.

When Michael Wara, the director of Stanford University’s Climate and Energy Policy Program, spoke with firefighters and insurance industry officials in the process of drafting a 2021 report for the Stanford Woods Institute for the Environment on strategies for mitigating wildfire risk, they told him that, from their perspective, wildfires are often a matter of “home ignition,” meaning that while building near forested areas puts any home at risk, the risk of a home itself igniting varies based on how it’s built and the vegetation clearance around it. “Existing homes in high fire threat areas” built before the implementation of California’s wildfire building codes, Wara wrote, “are a massive problem.” At the time he published the paper, there were somewhere between 700,000 and 1.3 million pre-building code homes still standing in “high or very high threat areas.”

The flipside of focusing on “home ignition” and the building code is that the building code works better over time, as more and more homes comply with it thanks to normal turnover, people extensively renovating, or even tearing down old homes — or rebuilding after fires. Homes that are close to homes that don’t ignite in a fire are more likely to survive.

One study that looked at the 2018 Camp Fire, which destroyed more than 18,000 structures and claimed more than 80 lives in the Northern California town of Paradise, sampled homes built before 1997, between 1997 and 2018, and from 2018 onwards, and found that only 11.5% of pre-1997 homes survived, compared to 38.5% from 1997 and after. The researchers also found that building survivability had a kind of magnifying effect, with distance from the nearest destroyed structure and the number structures destroyed in the immediate area among “the strongest predictors of survival.”

“The more homes that comply, the less chance you get those structural ignitions and the less chance you get those huge disasters like this,” Doug Green, who manages Headwaters Economics’ Community Assistance for Wildfire Program, told me. “It takes people doing the right thing to their own home — dealing with vegetation, making sure roofs are clean, having right roofing. It’s really a community-wide strategy to stop fires that happen like this.”

But just as any home hardening — or just building to code — is more effective the more the homes around you do it as well, it’s just as true in reverse. “If your next door neighbors don’t do that work, the effectiveness of your efforts will be less,” Dale said. “Building codes ultimately work best when we get an entire landscape or neighborhood to adopt them.”

Log in

To continue reading, log in to your account.

Create a Free Account

To unlock more free articles, please create a free account.

Current conditions: Springlike weather is bringing rain from Texas to Michigan • A Saharan dust storm known as a calima is headed for Europe, threatening “blood rain” as far north as Luxembourg • The Greenlandic capital of Nuuk is poised for days of snow, but with limited accumulation.

The aerial assault the United States and Israel launched on Iran this past weekend is already sending oil prices upward. By Sunday evening, the price for West Texas Intermediate crude, the benchmark for the oil drilled in the U.S., had risen 2.78% to just over $67 per barrel. Brent crude, the benchmark typically used to measure Europe’s production, 2.87% to nearly $73 per barrel. Murban crude, the benchmark set out of Abu Dhabi, surged by more than 4% to north of $74. By rendering the Strait of Hormuz — the waterway between the United Arab Emirates and Iran through which 15% of global oil flows and which tapers to just 20 miles wide at its narrowest point — impassable, the conflict could send prices per barrel as high as $100 or more, the consultancy Wood Mackenzie warned Sunday night. “The key question is when do vessels re-establish export flows,” Alan Gelder, Wood Mackenzie’s senior vice president of refining, chemicals and oil markets, said in a statement. “No doubt, tanker rates and insurance will increase dramatically, but these costs would only be a small part of the oil price impact associated with a curtailment of oil flows if they last for more than a few days.”

The rise in prices began weeks ago as the biggest U.S. troop buildup in the Middle East since 2003 seemed to presage war. The market isn’t just reflecting a fear of an unpredictable and prolonged halt to tanker traffic through the Strait. Insurers are threatening to cancel policies on vessels that dare to pass the waterway right now, the Financial Times reported. Iranian attacks on buildings and infrastructure belonging to America’s Arab allies across the Persian Gulf suggests the rest of the region’s oil production could face damage. “Right next door, you’ve got Iraq, you’ve got Saudi Arabia, and you’ve got the Emirates and others who collectively are more like 20 million barrels per day. And that is obviously a much bigger deal,” Rory Johnston, petroleum analyst and author of Commodity Context, told Heatmap’s Matthew Zeitlin.

A North Dakota judge finalized a $345 million judgement against Greenpeace USA on Friday, ordering the American chapter of the famed activist group to pay out the damages from its protests against the construction of the Dakota Access Pipeline. The ruling came after judge James Gion decided in October to slash almost half the $667 million that a jury awarded developer Energy Transfer Partners a year ago. The Dallas-based company called the ruling an “important step in this legal process of holding Greenpeace accountable for its unlawful and damaging actions against us.” In its own statement, Greenpeace said, “this is not the end of the case — or Greenpeace USA.” Rather, the group said it will request a new trial and, if necessary, “appeal the decision to the North Dakota Supreme Court.” The organization, which has since its founding in 1971 embarked on audacious acts of protest to raise awareness about environmental destruction, cast its fight against the ruling as a battle to protect Americans’ First Amendment rights. “In the years since the Standing Rock protests, anti-protest laws have spread across the U.S. and the world. Two of the most important components of change and progress throughout human history — free speech and peaceful protest – have never been more endangered,” Greenpeace said in the statement. “We must defend those rights. Our future depends on it.”

Last year, the International Seabed Authority, a little known United Nations agency based in Jamaica, debated how to establish rules for giving private companies permits to collect mineral-rich nodules off the deep ocean floor in waters far from any country’s maritime borders. Under outside pressure from the U.S., which is not a signatory to the ISA and has vowed under the Trump administration to go it alone on deep-sea mining, countries failed to reach an agreement. When the body reconvenes this week in the capital city of Kingston, the head of the ISA is determined to finalize a plan. In an interview with The New York Times, ISA chief Leticia Caravalho promised to broker a deal this year, lest an area in international waters become what she called the Wild West. “The world agreed 30 years ago that this is an area that belongs to all of us, and we should go there collectively,” she said. Banning mining outright, as some countries (and groups such as Greenpeace) have called for, would only take money away from scientific research and delay setting strict environmental protections, she said. “Being able to make the rules before activity starts is unique in human history,” she said.

Sign up to receive Heatmap AM in your inbox every morning:

The 220-megawatt ACES Delta green hydrogen project in Utah is by far the largest in the U.S. Now it’s ready to launch. As of last week, all 40 of the electrolyzers at the facility were installed and fully operational, supplier HydrogenPro told the trade publication Hydrogen Insight. It’s a critical milestone for a sector facing mounting challenges as the federal tax credit known as 45V begins its earlier phase out next year and the Trump administration yanks funding for the two regional hubs meant to hasten deployment of green hydrogen technology. Not every project is panning out as well. In New York, the developer Plug Power announced plans to abandon a 120-megawatt plant and sell the land to a data center company.

There’s a lot going on in hydrogen, including entirely new colors added to the rainbow scheme that describes how the fuel is made. If you want a quick 101 guide, this episode of Heatmap's Shift Key podcast is a good place to start.

At this stage in the new nuclear race, the company that looks likely to deploy the first small modular reactor in North America is GE Vernova Hitachi Nuclear Energy, the U.S.-Japanese joint venture building its debut BWRX-300 at the Darlington nuclear plant in Ontario, Canada. The developer is set to build another one of the third-generation, 300-megawatt reactors at the Tennessee Valley Authority soon after, and, as I reported for Heatmap, received major funding from the Department of Energy last year to pull it off. Until now, five European countries have been considering buying their own BWRX-300s: Czechia, Estonia, Finland, Poland, and Sweden. Now add a sixth. Lithuania just signed onto a memorandum of understanding in Washington promising to assess the potential to deploy the reactor, according to World Nuclear News.

There is a bright spot for clean energy in the Middle East. In Iraq, the first 250-megawatt section of what’s designed to be a 1-gigawatt solar farm is expected to enter operation in the next few days after the facility’s transmission connection powered on for the first time. Located in the Basra region, site of some of the bloodiest battles of the Iraq war, the project is a joint venture between the French giant TotalEnergies, which has a 45% stake; the Basrah Oil Company, which commands 30% of the solar farm; and QatarEnergy, with 25%, according to Renewables Now.

It starts — but doesn’t end — with the Strait of Hormuz.

For the second time in a year, the United States and Israel have launched a major aerial assault on Iran. Strikes were reported across the country early Saturday, targeting Iranian leadership and military infrastructure. In retaliation, Iran has launched attacks on Israel and Gulf nations allied with the U.S., with several of the targets appearing to be American military installations. “The United States military is undertaking a massive and ongoing operation,” President Trump said in a video posted to Truth Social explaining his rationale for launching the war.

While the conflict has quickly metastasized across the region, it has the potential to affect the entire world by disrupting the production and shipment of oil and natural gas.

Iran and its neighbors on the Persian Gulf are some of the largest oil and gas producers in the world and the country has long threatened to disrupt oil exports as an act of self-defense or retaliation from attack.

That may be already happening. According to data from Bloomberg, some oil tankers are pausing or turning around outside the vital Strait of Hormuz, a narrow, deep channel between Iran and Oman that connects the Persian Gulf to the Arabian Sea and thus to global markets in and bordering the Indian Ocean.

The strait has been “effectively closed,” according to a report from Tasnim, a semi-official news agency linked to the Iran Revolutionary Guard Corps. British naval officials also said they had “received multiple reports” of broadcasts that “have claimed that the Strait of Hormuz (SoH) has been closed.” And a European Union naval official told Reuters that the Iranian Revolutionary Guard had been broadcasting “no ship is allowed to pass the Strait of Hormuz” to ships in the area. Some tankers are still navigating the strait, according to marine tracking data from Kpler.

But it’s questionable whether Iran can actually maintain any attempted closure of the strait, whether by laying mines or directly threatening and attacking ships.

So far, U.S. attacks are “targeting, fairly heavily, naval assets and assets that are close to the Gulf,” Greg Brew, an analyst at the Eurasia Group, told me, which “suggests that they are trying to degrade Iran’s ability to disrupt energy traffic through the Strait of Hormuz.”

The U.S. is “trying to reduce the risks of Iranian effort to close the strait as part of this operation, rather than waiting to see if the Iranians escalate in that direction. The Iranians have responded by claiming that the strait has been closed. The problem for them now, though, is that they’ll have to enforce that threat.”

Closing the strait was a “tail risk” that had been roiling the oil market in the lead-up to Trump’s decision to launch the attack, Rory Johnston, petroleum analyst and author of Commodity Context, told me.

Global oil prices had gotten skittish over the past weeks, with the Brent crude benchmark getting as low at $66.30 per barrel in early February and getting near $73 per barrel on Friday. Brent prices approached $80 per barrel last June during the 12 Day War between Iran and Israel.

While the market could likely weather disruption to Iran’s own exports, jumpy behavior in the market was due to pricing in an enhanced risk of a region-wide calamity. Options traders especially were “attempting to hedge that enormous tail risk,” Johnston said, and “that was really moving the market.”

And even if the strait is not directly closed off by the Iranian military, ships may find it financially onerous to attempt the passage. “Insurers told ship owners on Saturday they would cancel policies and raise coverage prices for vessels travelling through the Gulf and Strait of Hormuz after the U.S. and Israel attacked Iran,” the Financial Times reported Saturday.

Another risk to the region’s oil sector is that Iran could retaliate by striking oil production and exporting infrastructure in neighboring countries, Johnston told me. “Right next door, you’ve got Iraq, you’ve got Saudi Arabia, and you’ve got the Emirates and others who collectively are more like 20 million barrels per day. And that is obviously a much bigger deal,” Johnston said, comparing their production to Iran’s own oil industry.

Of course, Iran is still a major exporter despite U.S. sanctions; in the days running up to the U.S. attack, it was shipping out around 3 million barrels per day from Kharg Island in the Strait of Hormuz, according to data from Bloomberg, almost triple its exports from equivalent dates in January and nearly its entire daily production.

Iran’s exports “had actually surged immediately ahead of what’s gone down over the past 24 hours,” Johnston told me. “In the past couple days, you’d seen a large surge of tankers departing Kharg Island, and the inventories on Kharg Island being drawn down, which is kind of what you would do if you expected that your exports were about to get disrupted.”

To the extent Iranian oil exports are cut off, that could be a big deal for China, which has become the number one destination for Middle East oil shipments. Beijing has been building up stockpiles of oil, likely preparing for the risk that sanctioned exporters like Iran and Venezuela would go off the market, as well as wider risks to exports from the Middle East.

“China is highly concerned over the military strikes against Iran,” the Chinese foreign ministry wrote on X. “China calls for an immediate stop of the military actions, no further escalation of the tense situation, resumption of dialogue and negotiation, and efforts to uphold peace and stability in the Middle East.”

Last year, China began to substantially increase its stockpiling of oil, going from 84,000 barrels per day to 430,000 barrels per day, some 83% of the growth of its imports, according to data and estimates from Rystad Energy and Erica Downs, a senior research scholar at the Columbia University Center on Global Energy Policy.

While the U.S. is now far less reliant on oil exports from the Middle East, oil and gas is still a global market. If Middle Eastern oil and gas exports are disrupted, that will likely increase the price of energy — whether it’s gasoline, electricity, or even home heating — as American energy producers can sell their barrels and BTUs at higher prices globally.

It’s either reassure investors now or reassure voters later.

Investor-owned utilities are a funny type of company. On the one hand, they answer to their shareholders, who expect growing returns and steady dividends. But those returns are the outcome of an explicitly political process — negotiations with state regulators who approve the utilities’ requests to raise rates and to make investments, on which utilities earn a rate of return that also must be approved by regulators.

Utilities have been requesting a lot of rate increases — some $31 billion in 2025, according to the energy policy group PowerLines, more than double the amount requested the year before. At the same time, those rate increases have helped push electricity prices up over 6% in the last year, while overall prices rose just 2.4%.

Unsurprisingly, people have noticed, and unsurprisingly, politicians have responded. (After all, voters are most likely to blame electric utilities and state governments for rising electricity prices, Heatmap polling has found.) Democrat Mikie Sherrill, for instance, won the New Jersey governorship on the back of her proposal to freeze rates in the state, which has seen some of the country’s largest rate increases.

This puts utilities in an awkward position. They need to boast about earnings growth to their shareholders while also convincing Wall Street that they can avoid becoming punching bags in state capitols.

Make no mistake, the past year has been good for these companies and their shareholders. Utilities in the S&P 500 outperformed the market as a whole, and had largely good news to tell investors in the past few weeks as they reported their fourth quarter and full-year earnings. Still, many utility executives spent quite a bit of time on their most recent earnings calls talking about how committed they are to affordability.

When Exelon — which owns several utilities in PJM Interconnection, the country’s largest grid and ground zero for upset over the influx data centers and rising rates — trumpeted its growing rate base, CEO Calvin Butler argued that this “steady performance is a direct result of a continued focus on affordability.”

But, a Wells Fargo analyst cautioned, there is a growing number of “affordability things out there,” as they put it, “whether you are looking at Maryland, New Jersey, Pennsylvania, Delaware.” To name just one, Pennsylvania Governor Josh Shapiro said in a speech earlier this month that investor-owned utilities “make billions of dollars every year … with too little public accountability or transparency.” Pennsylvania’s Exelon-owned utility, PECO, won approval at the end of 2024 to hike rates by 10%.

When asked specifically about its regulatory strategy in Pennsylvania and when it intended to file a new rate case, Butler said that, “with affordability front and center in all of our jurisdictions, we lean into that first,” but cautioned that “we also recognize that we have to maintain a reliable and resilient grid.” In other words, Exelon knows that it’s under the microscope from the public.

Butler went on to neatly lay out the dilemma for utilities: “Everything centers on affordability and maintaining a reliable system,” he said. Or to put it slightly differently: Rate increases are justified by bolstering reliability, but they’re often opposed by the public because of how they impact affordability.

Of the large investor-owned utilities, it was probably Duke Energy, which owns electrical utilities in the Carolinas, Florida, Kentucky, Indiana, and Ohio, that had to most carefully navigate the politics of higher rates, assuring Wall Street over and over how committed it was to affordability. “We will never waver on our commitment to value and affordability,” Duke chief executive Harry Sideris said on the company’s February 10 earnings call.

In November, Duke requested a $1.7 billion revenue increase over the course of 2027 and 2028 for two North Carolina utilities, Duke Energy Carolinas and Duke Energy Progress — a 15% hike. The typical residential customer Duke Energy Carolinas customer would see $17.22 added onto their monthly bill in 2027, while Duke Energy Progress ratepayers would be responsible for $23.11 more, with smaller increases in 2028.

These rate cases come “amid acute affordability scrutiny, making regulatory outcomes the decisive variable for the earnings trajectory,” Julien Dumoulin-Smith, an analyst at Jefferies, wrote in a note to clients. In other words, in order to continue to grow earnings, Duke needs to convince regulators and a skeptical public that the rate increases are necessary.

“Our customers remain our top priority, and we will never waver on our commitment to value and affordability,” Sideris told investors. “We continue to challenge ourselves to find new ways to deliver affordable energy for our customers.”

All in all, “affordability” and “affordable” came up 15 times on the call. A year earlier, they came up just three times.

When asked by a Jefferies analyst about how Duke could hit its forecasted earnings growth through 2029, Sideris zeroed in on the regulatory side: “We are very confident in our regulatory outcomes,” he said.

At the same time, Duke told investors that it planned to increase its five-year capital spending plan to $103 billion — “the largest fully regulated capital plan in the industry,” Sideris said.

As far as utilities are concerned, with their multiyear planning and spending cycles, we are only at the beginning of the affordability story.

“The 2026 utility narrative is shifting from ‘capex growth at all costs’ to ‘capex growth with a customer permission slip,’” Dumoulin-Smith wrote in a separate note on Thursday. “We believe it is no longer enough for utilities to say they care about affordability; regulators and investors are demanding proof of proactive behavior.”

If they can’t come up with answers that satisfy their investors, ultimately they’ll have to answer to the voters. Last fall, two Republican utility regulators in Georgia lost their reelection bids by huge margins thanks in part to a backlash over years of rate increases they’d approved.

“Especially as the November 2026 elections approach, utilities that fail to demonstrate concrete mitigants face political and reputational risk and may warrant a credibility discount in valuations, in our view,” Dumoulin wrote.

At the same time, utilities are dealing with increased demand for electricity, which almost necessarily means making more investments to better serve that new load, which can in the short turn translate to higher prices. While large technology companies and the White House are making public commitments to shield existing customers from higher costs, utility rates are determined in rate cases, not in press releases.

“As the issue of rising utility bills has become a greater economic and political concern, investors are paying attention,” Charles Hua, the founder and executive director of PowerLines, told me. “Rising utility bills are impacting the investor landscape just as they have reshaped the political landscape.”