You’re out of free articles.

Log in

To continue reading, log in to your account.

Create a Free Account

To unlock more free articles, please create a free account.

Sign In or Create an Account.

By continuing, you agree to the Terms of Service and acknowledge our Privacy Policy

Welcome to Heatmap

Thank you for registering with Heatmap. Climate change is one of the greatest challenges of our lives, a force reshaping our economy, our politics, and our culture. We hope to be your trusted, friendly, and insightful guide to that transformation. Please enjoy your free articles. You can check your profile here .

subscribe to get Unlimited access

Offer for a Heatmap News Unlimited Access subscription; please note that your subscription will renew automatically unless you cancel prior to renewal. Cancellation takes effect at the end of your current billing period. We will let you know in advance of any price changes. Taxes may apply. Offer terms are subject to change.

Subscribe to get unlimited Access

Hey, you are out of free articles but you are only a few clicks away from full access. Subscribe below and take advantage of our introductory offer.

subscribe to get Unlimited access

Offer for a Heatmap News Unlimited Access subscription; please note that your subscription will renew automatically unless you cancel prior to renewal. Cancellation takes effect at the end of your current billing period. We will let you know in advance of any price changes. Taxes may apply. Offer terms are subject to change.

Create Your Account

Please Enter Your Password

Forgot your password?

Please enter the email address you use for your account so we can send you a link to reset your password:

An interview with Ola Källenius on Mercedes-Benz’s road to electrification.

Back in 2019 Mercedes-Benz announced that it would go fully electric by 2030 where markets allow, and the brand is rapidly heading towards that goal. Every new platform and powertrain developed by Mercedes starting from 2025 will be electric, with the current set of gas engines designed to last through the next few product life cycles until being phased out.

Even more importantly, according to Mercedes-Benz’s chairman of the board and CEO Ola Källenius, Mercedes will be completely carbon-neutral by 2039, a plan it calls Ambition 2039. This was derived from the Paris Climate Agreement, which aims for the world to be net zero by 2050. I sat down with Källenius at a roundtable in Vienna during the first drive of the new E-Class – still an internal-combustion car, but one with electrified powertrains – to learn more about Mercedes’ decarbonization plans, EV strategy, and overall outlook on the future of the automotive industry.

“Mercedes-Benz is a brand that stands for the promise of a better future, and that better future is fundamentally a zero-emissions business,” says Källenius, adding that the decarbonization goal will happen in just three product life cycles. He also believes that Mercedes could actually hit its decarbonization goal a little early, closer to the start of the 2030s than the end.

It’s not just people inside the company that want this to happen, either. “There’s not a single long investor in Mercedes stock that doesn’t believe the company needs to decarbonize,” Källenius says. “Even if there weren’t regulatory will, we’re at the point where the financial market made up its mind that a sustainable business strategy is the one that is more economically safe.” He adds that even investors with fossil-based revenue streams are heavily investing in new verticals.

Källenius also thinks aggressively pursuing decarbonization will let Mercedes stay nimble. “We already have strategic clarity; we know what the journey and destination is, and it’s zero emissions,” he says. “But during this transformation, which is more than a decade long and it’s difficult to judge exactly when and what will happen, we need tactical flexibility and we have that.” This means that when the industry gets to the point where the new technology unseats the incumbent technology and there is exponential growth, Mercedes needs to be (and already is) in a position where it doesn’t fall behind. Källenius describes Mercedes as being its own venture capitalist, as it’s in control over financing for its transition to EVs.

All of Mercedes’ global assembly plants have already been made powertrain flexible, so a shift to more EV production will be easy, Källenius argues. Mercedes recently transformed its Alabama facility to produce the EQE and EQS SUVs for global consumption, for example.

Also important to decarbonization is the manufacturing process. “The defining challenge of our generation is to take care of the CO2 problem,” says Källenius, “and it has to be from A to Z, all the suppliers, all our operations, the car itself and the car in use. The twin of the CO2 problem is a circular economy. How do we reduce the use of primary materials in the production of goods? It’s an even bigger problem to solve technologically and economically.” For most current car manufacturers the secondary material content – materials that have been used or recycled – is between 20 to 30 percent. Mercedes is targeting 40 percent by 2030. “That might not sound ambitious, but believe me, engineering-wise it’s unbelievably ambitious,” Källenius says.

The idea is to decouple economic growth from resource usage growth, especially when it comes to EV batteries as they are made up of precious materials like lithium, manganese and cobalt. Mercedes is building its own experimental battery recycling and research factory along with some partners, and prototypes have already been developed that can get recycling quotes into “the deep 90 percent” range. It’s also working with German chemical companies to go through every polymer category and figure out recycling options category by category. Källenius says that one day batteries coming back from vehicles will be “the biggest virtual mine in the world.”

You might think it would be hard to get Mercedes’ suppliers and partners on board with the Ambition 2039 plan, but according to Källenius that wasn’t the case. “When we defined Ambition 2039 it only works if all our suppliers go CO2 neutral as well. If you’re not on board with the program, you’re not on board,” says Källenius. “If all things are equal from performance to quality and price, in a competitive bid if one company has a better plan for decarbonization than the other, that could be the kind of thing that tips the scale.”

Once a year Mercedes holds a conference where it invites 500 of its most important suppliers to go over the year’s results and plan for the future, and at the first one in 2019 after announcing Ambition 2039 the company told its suppliers that it expected each one to come up with an equivalent plan. “The reaction back then from some of the more progressive companies was ‘welcome to the club, you are preaching to the choir,’ and for many in the room it was ‘oh shit, these guys are serious,’” remembers Källenius. “Now I would say 90 percent of our suppliers have a plan.”

Some of Mercedes’ steel suppliers are already deep into carbon-free steel production, with the first results to be in production cars in less than two years. One of the companies, the Swedish firms H2GS, should be carbon-free by 2030 thanks to the use of hydroelectric power. As another example, Mercedes is working with an aluminum producer to reduce its carbon footprint by 70 percent. “Ten years ago, pretty much everyone around the table would’ve said ‘that’s not possible, it’s not gonna happen,’” says Källenius. “Now it’s happening.”

Källenius says the two core technologies driving the shift to EVs are the electric drivetrains and the software, and vertical integration is extremely important to both. For instance, Mercedes owns everything about its powertrains all the way down to the battery chemistry.

The vertical integration is tougher when it comes to the digital side of things. Traditionally electronic architectures in cars have been decentralized – when automakers buy an ECU they buy an entire software package along with it, and the car manufacturer then integrates the functionality. “We said we need to control the brain and central nervous system of the car,” says Källenius. Having this much centralized control over the software means updates and improvements can be made much quicker than before.

The new E-Class is the first Mercedes to have the updated MBUX operating system and cloud infrastructure, in which every single line of code has been programmed by Mercedes for the first time.

Like nearly every other carmaker, Mercedes recently announced that its future EVs will use the NACS charge port pioneered by Tesla. NACS will soon become an SAE standard, which Källenius says played into the decision to switch. “We always do what we think is best for the customer in terms of convenience, and the most likely scenario is NACS,” says Källenius. The first NACS-equipped Benzes won’t start coming out until around 2025, and in the meantime the brand will offer an adapter for existing EVs with the CCS charge port.

Automakers have never historically worked on gas station infrastructure, leaving that to energy companies, but in the electric era that is changing too. Accessible fast charging is potentially the largest pain point for EV customers, so more car companies are figuring out their own solutions to help aid the lagging infrastructure. Later this year Mercedes will open its first high-speed charging stations in the US, with 10,000 coming to America, China and Europe by the end of the decade as part of a multi-billion-dollar investment. The switch to NACS will help in the meantime, allowing Mercedes EV drivers to use Tesla’s expansive Supercharger network. “While we’re building our charging infrastructure, why not offer the Mercedes customer access to the 12,000 chargers built by another company,” Källenius says, “it will create more convenience and maybe take away a little bit of doubt for people that are thinking about buying an EV.”

When it comes to passenger cars Källenius says EVs are the clear way forward versus hydrogen or other synthetic fuels, but those solutions could have other uses. Shipping is one of the biggest issues when it comes to decarbonization; for mass-volume models it’s easy enough to build a local factory in China or the U.S., but for a low-volume model like the SL sports car it’s not economically feasible to have multiple production locations. Mercedes is maximizing its use of shipping by rail, especially in countries like Germany where it’s more feasible, and it’s experimenting with using hydrogen for semi trucks. Overseas and air shipping is even tougher to decarbonize, but synthetic fuels could help with that in the future too.

Källenius just celebrated his 30th anniversary at Mercedes, and he says right now is the most exciting time to be in the industry because everything is changing.

“We have to reinvent the original invention.,” he says. “We have got to be Gottlieb Daimler and Karl Benz again.”

Log in

To continue reading, log in to your account.

Create a Free Account

To unlock more free articles, please create a free account.

CarbonPlan has a new tool to measure climate risk that comes with full transparency.

On a warming planet, knowing whether the home you’re about to invest your life savings in is at risk of being wiped out by a wildfire or drowned in a flood becomes paramount. And yet public data is almost nonexistent. While private companies offer property-level climate risk assessments — usually for a fee — it’s hard to know which to trust or how they should be used. Companies feed different datasets into their models and make different assumptions, and often don’t share all the details. The models have been shown to predict disparate outcomes for the same locations.

For a measure of the gap between where climate risk models are and where consumers want them to be, look no further than Zillow. The real estate website added a “climate risk” section to its property listings in 2024 in response to customer demand — only to axe the feature a year later at the behest of an industry group that questioned the accuracy of its risk ratings.

Now, however, a new tool that assesses wildfire risk for every building in the United States aims to advance the field through total transparency. The nonprofit research group CarbonPlan launched the free, user-friendly app called Open Climate Risk on Tuesday. It allows anyone to enter an address and view a wildfire risk score, on a scale of zero to 10, along with an explanation of how it was calculated. The underlying methodology, data, and code are all public. It’s the first fully open platform of its kind, according to CarbonPlan.

“Right now, the way science works in the climate risk space is that every model is independently developed at different companies, and we essentially have no idea what’s happening in them. We have no idea if they’re any good,” Oriana Chegwidden, a research scientist at CarbonPlan who led the creation of the tool, told me. “Our hope is that by opening this up, people will be able to start contributing, to help us learn how we can do it better.” That might mean critiquing CarbonPlan’s methods or code, for example, or re-running the model with additional data.

The score itself doesn’t tell you much other than the relative risk between one building and another. But the platform also breaks out the two inputs behind it: burn probability, or the likelihood a building will catch fire in a given year, and “conditional risk,” an estimate of how much of the building’s value would be lost if it does burn, based on projected fire intensity.

The projections are largely based on a U.S. Forest Service dataset that models fire frequency on wildlands throughout the country. CarbonPlan uses additional data on wind speed and direction to predict how a given fire might spread into an urban area.

Users can toggle between risk under the “current” climate and a “future” climate, which jumps about 20 years out. They can also see the distribution of buildings across the spectrum of risk scores at various geographic scales — by state, county, census tract, or census block.

One of CarbonPlan’s hopes is to help people become more informed consumers of climate risk data by helping them understand how it’s put together and what questions they might want to ask. While its model is more crude than others on the market, the tool is explicit about the factors that are not accounted for in the results. The loss estimates are based on a generic building, for example, and do not recognize specific traits like fire-resistant construction materials or landscaping that could make a home more fire resistant. They also don’t consider building-to-building spread. The underlying U.S. Forest Service data is also limited in that it maps vegetation across the country as it existed at the end of 2020 — any changes since then that could have reduced fire-igniting fuels, such as prescribed burns, are not incorporated.

Right now, there’s no industry standard for calculating or communicating climate risk. The Global Association of Risk Professionals recently asked 13 climate risk companies for data on floods, tropical storms, wildfires, and heat at 100 addresses to compare the outputs. The authors found there were “significant disparities,” between estimates of vulnerability and damages at the same locations. When it came to wildfires, specifically, they were unable to even compare the data, because the companies all conveyed the risk using different benchmarks.

The implications of having so many diverging methods and results extend beyond individual homebuying decisions. Insurance companies use climate risk data to set rates; publicly-traded companies use it to make disclosures to investors; policymakers use it to guide community planning and investments in adaptation. Some products might be better suited to one task or another.

Katherine Mach, an environmental science and policy professor at the University of Miami, told me the next step for the field is to have more systematic reporting requirements that help people understand how accurate the data are and what types of decisions they can be used for.

“It’s almost like we need the equivalent of industry standards,” she said. “You’re going to release a climate product? Here’s what you need to clearly communicate.”

CarbonPlan collected feedback from various likely users of the tool throughout the development process, including municipal planners, climate scientists, and consumer advocates. The group also hopes to foster an “iterative cycle of community-driven model development,” spurring other researchers to inspect the data, critique it, add to it, and spin out new versions. This is common practice in other areas of climate science, like Earth system modeling and economic modeling, and has been instrumental in advancing those fields. “There’s nothing like that for climate risk right now,” Chegwidden said.

The first step will be raising more money to support further work, but the goal is to partner with outside researchers on comparative analyses and case studies. Tracy Aquino Anderson, CarbonPlan’s interim executive director, told me they have already heard from one researcher who has a fire risk dataset that could be added to the platform. The group has also been invited to present the platform to two academic climate research groups later this spring.

The problem of black box models exists not just because the field is full of private companies that don’t want to share their code. A study published earlier this month found that only 4% of the most-cited peer-reviewed climate risk studies have made their data and code public, despite journal standards that require transparency.

“When you’re working with climate data, you’re dealing with all of these uncertainties,” Adam Pollack, an assistant professor at the University of Iowa who researches flood risk and the lead author of the paper, told me. “Researchers don’t always understand all of the assumptions that are implicit in choices that they make. That’s fine — we have methods for dealing with that. We do model intercomparisons, we do these synthesis studies as a field. The foundation of that is openness and reusability.”

Though he was not involved in the CarbonPlan project, he said it was exactly what his paper was calling for. For example, CarbonPlan’s “future” calculations are based on an extreme warming scenario that has become controversial among climate scientists. CarbonPlan didn’t choose this scenario — it’s what the Forest Service’s dataset used, and that was the only off-the-shelf data available for the entire United States. But because the underlying code is open-source, critics are free to swap it out for other data they may have access to.

“That’s what’s so great about this,” Pollack said. “People who have different values, assumptions, and expertise, can get new estimates and build a shared understanding.”

On BYD’s lawsuit, Fervo’s hottest well, and China’s geologic hydrogen

Current conditions: A midweek clipper storm is poised to bring as much as six more inches of snow to parts of the Great Lakes and Northeast • American Samoa is halfway through three days of fierce thunderstorms and temperatures above 80 degrees Fahrenheit • Northern Portugal is bracing for up to four inches more of rain after three deadly storms in just two weeks.

The Environmental Protection Agency is preparing this week to repeal the Obama-era scientific finding that provides the legal basis for virtually all federal regulations of planet-heating emissions, marking what The Wall Street Journal called “the most far-reaching rollback of U.S. climate policy to date.” The 2009 “endangerment finding” concluded that greenhouse gases pose a threat to public health and welfare, calling for cuts to emissions from power plants and vehicle tailpipes. EPA Administrator Lee Zeldin told the newspaper the move “amounts to the largest act of deregulation in the history of the United States.” In an interview with my colleague Emily Pontecorvo last year, Harvard Law School’s Jody Freeman said rescinding the endangerment finding would do “more serious and more long term damage” and “could knock out a future administration from trying to” bring back climate policy. But that, Freeman said, would depend on the Supreme Court backing the administration. “I don’t think that’s likely, but it’s possible,” she said.

At issue is the 2007 case Massachusetts v. EPA, which determined that greenhouse gases qualified as pollutants under the Clean Air Act. As Emily wrote last week, “the agency claims that its previous read of Massachusetts v. EPA was wrong, especially in light of subsequent Supreme Court decisions, such as West Virginia v. EPA and Loper Bright v. Raimondo. The former limited the EPA's toolbox for regulating power plants, and the latter ended a requirement that courts defer to agency expertise in cases where the law is vague.” An earlier report in The Washington Post questioned whether the agency would proceed with the repeal at all, fearing these arguments would pass muster in the nation’s highest court.

BYD has sued the United States government over the 100% tariff on Chinese electrics that serves as an effective ban on Beijing’s booming auto exports. Four U.S.-based subsidiaries of the world’s largest manufacturer of electric vehicles filed a lawsuit in the U.S. Court of International Trade challenging the legality of the Trump administration’s trade levies. The litigation marks what the state-backed tabloid Global Times called “the first instance of a Chinese automaker directly and actively challenging U.S. tariffs, setting a precedent and carrying significance for Chinese enterprises to protect their legitimate rights and interests through legal means.”

Outside the U.S., BYD is booming. China’s cheap electric cars are popular all over the world, as Heatmap’s Shift Key podcast covered in December. Canadian Prime Minister Mark Carney’s deal to increase trade with China will bring the battery-powered vehicles to North American roads. And the Chinese edition of the trade publication Automotive News just reported that BYD is planning a factory expansion in Europe and Canada.

Hot off last month’s news that it plans to go public, Fervo Energy has drilled its highest-temperature well yet. The drilling results confirm that the next-generation geothermal startup tapped into a resource with temperatures above 555 degrees Fahrenheit at approximately 11,200 feet deep. The company announced the findings Monday of an independent assessment using appraisal data from the drilling. The analysis found that the Project Blanford site in Millard County, Utah, has multiple gigawatts of heat that can be harnessed. Its completion will be a breakthrough for enhanced geothermal systems, one of two leading approaches to the next-generation geothermal sector that Heatmap’s Matthew Zeitlin outlined here. “This latest ultra-high temperature discovery highlights our team’s ability to detect and develop EGS sweet spots using AI-enhanced geophysical techniques,” Jack Norbeck, Fervo’s co-founder and chief technology officer, said in a statement.

Sign up to receive Heatmap AM in your inbox every morning:

Chinese scientists have for the first time discovered natural hydrogen sealed in microscopic inclusions near Tibet. The finding, which the Xinhua news agency called “groundbreaking,” fills what the China Hydrogen Bulletin called “a major domestic research gap and points to a new geological pathway for identifying China’s next generation of clean energy resources.” Natural, or geological, hydrogen could provide a cheap source of the zero-carbon fuel and give oil and gas drillers a natural foothold in a new, clean industry. In the color spectrum associated with hydrogen, the rare, naturally formed stuff is called white hydrogen. But as Heatmap’s Katie Brigham wrote in December, a new color has joined the rainbow. Orange hydrogen refers to a family of technologies that naturally spur production of the gas, as the startup Vema is now attempting to do.

China’s coal-fired power generation decreased 1.9% last year, marking what the consultancy Wood Mackenzie called “a historic shift driven by new non-fossil generation that has finally outpaced demand growth.” Power demand surged 5% in China last year, but for the first time in a decade that wasn’t propelled by coal plants. Instead, that new demand was supplied by renewables, nuclear, and hydro, all of which Beijing has rapidly deployed. Over that time, the levelized cost of energy — a widely used though, as Matthew wrote last year, far-from-perfect metric — fell 77% for utility-scale solar and 73% for onshore wind. “At the heart of this transformation is the unprecedented expansion of renewable energy capacity,” Sharon Feng, a senior research analyst for Wood Mackenzie, said in a statement. “China’s wind and solar capacity had risen more than ten-fold to 1,842 gigawatts over the past decade.”

Gone are the days when the oil industry seemed to be on track for a lucrative decline. Demand for crude will take longer to peak than previously estimated as governments prioritize growth and energy security over efforts to curb consumption. That’s according to a report issued Sunday by Vitol Group, the world’s largest independent oil trader. “Over the past year, decarbonisation policies have become a less decisive driver of efforts to curb oil consumption and reduce carbon dioxide emissions,” the report stated, according to Bloomberg. “Policy priorities have increasingly been reframed around economic competitiveness and geopolitical strategy.”

The race for a long-duration energy storage solution has a new competitor. The Dutch startup Ore Energy has deployed its iron-air storage technology successfully on the grid for a technical pilot of its system that can store for 100 hours of power. The pilot, the first of its kind in Europe, demonstrated that the company’s technology can store and discharge energy for up to four days. “This pilot allowed us to evaluate iron-air performance under European operating profiles and real-world grid conditions,” Aytaç Yilmaz, co-founder and CEO of Ore Energy, said in a statement.

Wildfires are moving east.

There were 77,850 wildfires in the United States in 2025, and nearly half of those — 49% — ignited east of the Mississippi River, according to statistics released last week by the National Interagency Fire Center. That might come as a surprise to some in the West, who tend to believe they hold the monopoly on conflagrations (along with earthquakes, tsunamis, and megalomaniac tech billionaires).

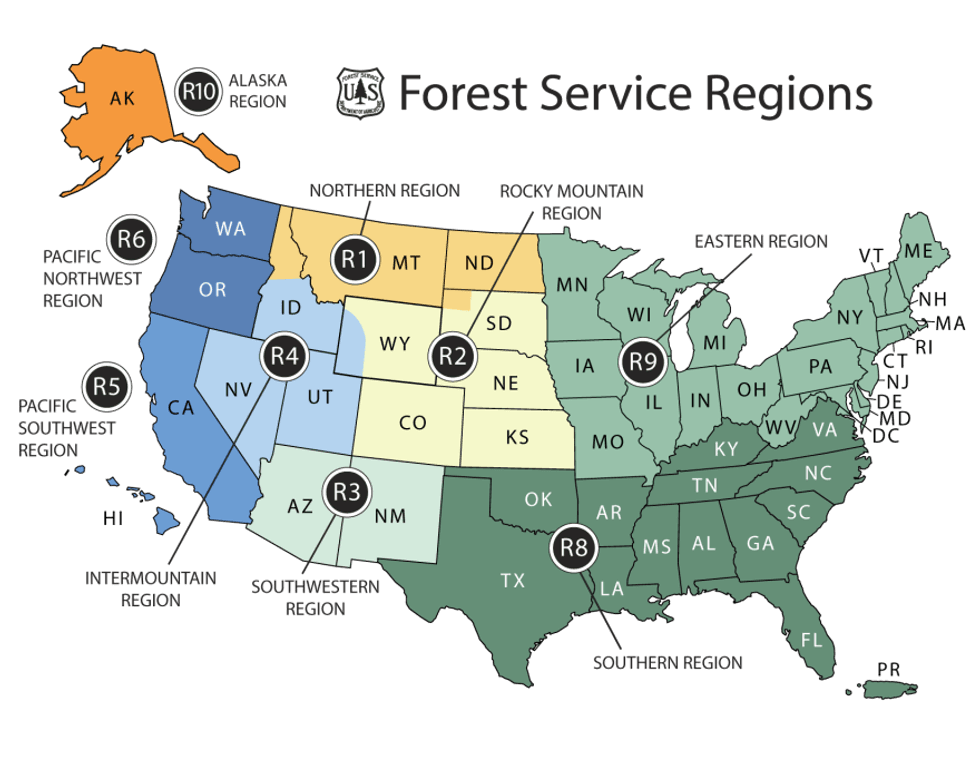

But if you lump the Central Plains and Midwest states of Minnesota, Iowa, Missouri, Arkansas, Oklahoma, and Texas along with everything to their east — the swath of the nation collectively designated as the Eastern and Southern Regions by the U.S. Forest Service — the wildfires in the area made up more than two-thirds of total ignitions last year.

Like fires in the West, wildfires in the eastern and southeastern U.S. are increasing. Over the past 40 years, the region has seen a 10-fold jump in the frequency of large burns. (Many risk factors contribute to wildfires, including but not limited to climate change.)

What’s exciting to wildfire researchers and managers, though, is the idea that they could catch changes to the Eastern fire regime early, before the situation spirals into a feedback loop or results in a major tragedy. “We have the opportunity to get ahead of the wildfire problem in the East and to learn some of the lessons that we see in the West,” Donovan said.

Now that effort has an organizing body: the Eastern Fire Network. Headed by Erica Smithwick, a professor in Penn State’s geography department, the research group formed late last year with the help of a $1.7 million, three-year grant from the Gordon and Betty Moore Foundation, a partner with the U.S. National Science Foundation, with the goal of creating an informed research agenda for studying fire in the East. “It was a very easy thing to have people buy into because the research questions are still wide open here,” Smithwick told me.

Though the Eastern U.S. is finally exiting a three-week block of sub-freezing temperatures, the hot, dry days of summer are still far from most people’s minds. But the wildland-urban interface — that is, the high-fire-risk communities that abut tracts of undeveloped land — is more extensive in the East than in the West, with up to 72% of the land in some states qualifying as WUI. The region is also much more densely populated, meaning practically every wildfire that ignites has the potential to threaten human property and life.

It’s this density combined with the prevalent WUI that most significantly distinguishes Eastern fires from those in the comparatively rural West. One fire manager warned Smithwick that a worst-case-scenario wildfire could run across the entirety of New Jersey, the most populous state in the nation, in just 48 hours.

Generally speaking, though, wildfires in the East are much smaller than those in the West. The last megafire in the Forest Service’s Southern Region was as far west in its boundaries as you can get: the 2024 Smokehouse Creek fire in Texas and Oklahoma, which burned more than a million acres. The Eastern Region hasn’t had a megafire exceeding 100,000 acres in the modern era. For research purposes, a “large” wildfire in the East is typically defined as being 200 hectares or more in size, the equivalent of about 280 football fields; in the West, a “large” wildfire is twice that, 400 hectares or more.

But what the eastern half of the country lacks in total acres burned (for that statistic, Alaska edges out the Southern Region), it makes up for in the total number of reported ignitions. In 2025, for example, the state of Maine alone recorded 250 fires in August, more than doubling its previous record of just over 100 fires. “The East is highly fragmented,” Donovan, who is contributing to the Eastern Fire Network’s research, told me. “We have a lot of development here compared to the West, and so it’s much more challenging for fires to spread.”

Fires in the West tend to be long-duration events, burning for weeks or even months; fires in the East are often contained within 48 hours. In New Jersey, for example, “smaller, fragmented forests, which are broken up by numerous roads and the built environment, [allow] firefighters to move ahead of a wildfire to improve firebreaks and begin backfiring operations to help slow the forward progression,” a spokesperson for the New Jersey Forest Fire Service told me.

The parcelized nature of the eastern states is also reflected in who is responding to the fires. It is more common for state agencies and local departments — including many volunteer firefighting departments — to be the ones on the scene, Debbie Miley, the executive director of the National Wildfire Suppression Association, a trade group representing private wildland fire service contractors, told me by email. On the one hand, the local response makes sense; smaller fires require smaller teams to fight them. But the lack of a joint effort, even within a single state, means broader takeaways about mitigation and adaptation can be lost.

“Many eastern states have strong state forestry agencies and local departments that handle wildfire as part of an ‘all hazards’ portfolio,” Miley said. “In the West, there’s often a deeper bench of personnel and systems oriented around long-duration wildfire campaigns (though that varies by state).”

All of this feeds into why Smithwick believes the Eastern Fire Network is necessary: because of this “intermingling, at a very fine scale, of different jurisdictional boundaries,” conversations about fire management and the changing regimes in the region happen in parallel, rather than with meaningful coordination. Even within a single state, fire management might be divided between different agencies — such as the Game Commission and the Bureau of Forestry, which share fire management responsibilities in Pennsylvania. Fighting fires also often involves working with private landowners in the East; in the West, on the other hand, roughly two-thirds of wildfires burn on public land, which a single agency — e.g. the Bureau of Land Management, Forest Service, or Park Service — manages.

But “wildfire risk is going to be different than in the West, and maybe more variable,” Smithwick told me. Identifying the appropriate research questions about that risk is one of the most important objectives of the Eastern Fire Network.

Bad wildfires are the result of fuel and weather conditions aligning. “We generally know what the fuels are [in the East] and how well they burn,” Smithwick said. But weather conditions and their variability are a greater question mark.

Nationally, fire and emergency managers rely on indices to predict fire-weather risk based on humidity, temperature, and wind. But while those indices are dialed in for the Western states, they’re less well understood in the East. “We hope to look at case studies of recent fires that have occurred in the 2024 and 2025 window to look at the antecedent conditions and to use those as case studies for better understanding the mechanisms that led to that wildfire,” Smithwick said.

Learning more about the climatological mechanisms driving dry spells in the region is another explicit goal. Knowing how dry spells evolve, and where, will help researchers and eventually policymakers to identify mitigation strategies for locations most at risk. Smithwick also expects to learn that some areas might not be at high risk: “We can tell you that this is not something your community needs to invest in right now,” she told me.

Different management practices, jurisdictions, terrains, and fuel types mean solutions in the East will look different from those in the West, too. As Donovan’s research has found, the unmanaged regrowth of forests in the northeast in particular after centuries of deforestation has led to an increase in trees and shrubs that are prone to wildfires. Due to the smaller forest tracts in the area, mechanical thinning is a more realistic solution in eastern forests than on large, sprawling, remote western lands.

Prescribed burns tend to be more common and more readily accepted practices in the East, too. Florida leads the nation in preventative fires, and the New Jersey Forest Fire Service aims to treat 25,000 acres of forest, grasslands, and marshlands with prescribed fire annually.

The winter storms that swept across the Eastern and Southern regions of the United States last month have the potential to queue up a bad fire season once the land starts to thaw and eventually dry out. Though the picture in the Eastern Region is still coming into focus depending on what happens this spring, in the Southern region the storms have created “potential compaction of the abundant grasses across the Plains, in addition to ice damage in pine-dominant areas farther east,” the National Interagency Fire Center wrote in last Monday’s update to its nationwide fire outlook. (The nearly million-acre Pinelands of New Jersey are similarly a fire-adapted ecosystem and are “comparable in volatility to the chaparral shrublands found in California and southern Oregon,” the spokesperson told me.)

The compaction of grasses is significant because, although they will take longer to dry and become a fuel source, it will ultimately leave the Southern region covered with a dense, flammable fuel when summer is in full swing. Beyond the Plains, in the Southeast’s pine forests, the winter-damaged trees could cast “abundant” pine needles and “other fine debris” that could dry out and become flammable as soon as a few weeks from now. “Increased debris burning will also amplify ignitions and potential escapes, enhancing significant fire potential during warmer and drier weather that will return in short order,” NIFC goes on to warn.

Though the historically wet Northeast and humid Southeast seem like unlikely places to worry about large wildfires, as conditions change, nothing is certain. “If we learned anything from fire science over the past few decades, it’s that anywhere can burn under the right conditions,” Smithwick said. “We are burning in the tundra; we are burning in Canada; we are burning in all of these places that may not have been used to extreme wildfire situations.”

“These fires could have a large economic and social cost,” Smithwick added, “and we have not prepared for them.”