You’re out of free articles.

Log in

To continue reading, log in to your account.

Create a Free Account

To unlock more free articles, please create a free account.

Sign In or Create an Account.

By continuing, you agree to the Terms of Service and acknowledge our Privacy Policy

Welcome to Heatmap

Thank you for registering with Heatmap. Climate change is one of the greatest challenges of our lives, a force reshaping our economy, our politics, and our culture. We hope to be your trusted, friendly, and insightful guide to that transformation. Please enjoy your free articles. You can check your profile here .

subscribe to get Unlimited access

Offer for a Heatmap News Unlimited Access subscription; please note that your subscription will renew automatically unless you cancel prior to renewal. Cancellation takes effect at the end of your current billing period. We will let you know in advance of any price changes. Taxes may apply. Offer terms are subject to change.

Subscribe to get unlimited Access

Hey, you are out of free articles but you are only a few clicks away from full access. Subscribe below and take advantage of our introductory offer.

subscribe to get Unlimited access

Offer for a Heatmap News Unlimited Access subscription; please note that your subscription will renew automatically unless you cancel prior to renewal. Cancellation takes effect at the end of your current billing period. We will let you know in advance of any price changes. Taxes may apply. Offer terms are subject to change.

Create Your Account

Please Enter Your Password

Forgot your password?

Please enter the email address you use for your account so we can send you a link to reset your password:

Two U.S.-based companies are betting on lithium-sulfur to compete with China.

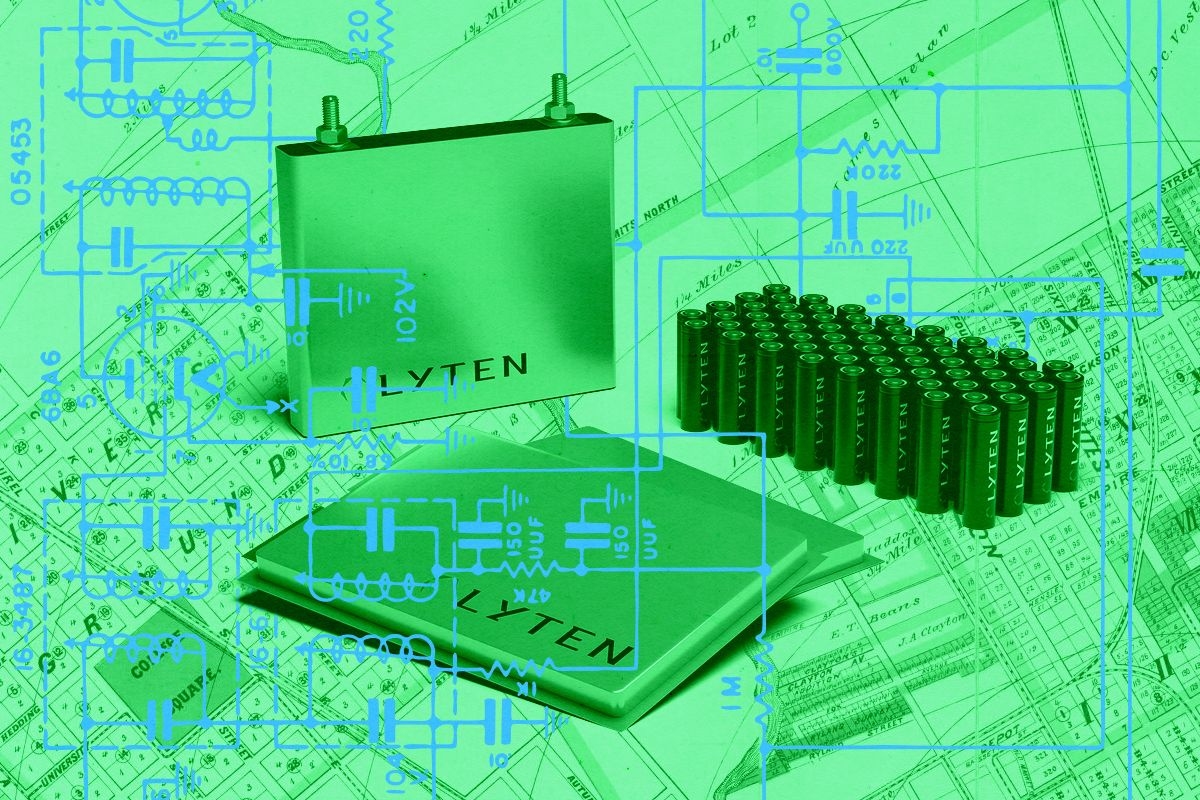

By the time the Swedish battery giant Northvolt declared bankruptcy last month, a well-funded U.S. startup, Lyten, had already swooped in to snatch up the company’s previously shuttered Bay Area factory. With China flooding the market with its cheap lithium-ion tech, Lyten is betting that creating a fully domestic battery supply chain will require alternate chemistries — like, say, lithium-sulfur, Lyten’s recipe of choice.

Lithium-sulfur has long been a promising contender, as in theory, these batteries can have a much higher energy density — the amount of energy that can be stored in a given space — than traditional lithium-ion. They also rely primarily on cheap, abundant, and easy to access materials. “We don’t use nickel, we don’t use manganese, we don’t use cobalt, we don’t use graphite,” Keith Norman, Lyten’s chief sustainability officer, told me — all markets where China plays a leading role. Scaling up standard lithium-ion battery production to meet forecasted global demand would require opening nearly 400 new mines by 2035, according to Benchmark Mineral Intelligence. “We believe if you could snap your fingers and change that to lithium-sulfur, that mining requirement will be reduced somewhere between 80% and 90%,” Norman said.

Lyten’s customers, Norman said, want these batteries as soon as possible, and acquiring Northvolt’s old 200-megawatt plant will allow the company to begin commercial production there next year. Lyten also recently announced plans for a Reno-based gigafactory, which is scheduled to come online in 2027. Zeta Energy, a Houston-based lithium-sulfur startup, also aims to commercialize in 2025, and is set to announce the opening of its 100-megawatt plant in the coming weeks.

While both companies have dreams of enabling more efficient, lightweight, and cost-effective electric vehicles and energy storage systems, there are reasons why lithium-sulfur has yet to be commercialized.

For one, sulfur is generally a poor conductor of lithium ions, and therefore requires extra conductive material to compensate, increasing the battery’s weight. Lithium-sulfur batteries also have notoriously short cycle lives due to the “polysulfide shuttle effect,” which causes the sulfur in the cathode to dissolve in the liquid electrolyte, damaging the anode and — you guessed it — decreasing the battery’s capacity and cycle life.

“It could be solved,” Arumugam Manthiram, an engineering professor and battery researcher at the University of Texas at Austin, told me. After being involved in the initial lithium-ion battery breakthroughs of the 1980s, Manthiram said he’s seen traditional battery tech continue to improve year after year. He thinks lithium-sulfur will follow the same trajectory, only quicker. “Can it be solved in five years, 10 years? I’m optimistic.” he told me. He’s currently working with Lyten on a Department of Energy-funded grant to accelerate the commercialization of lithium-sulfur batteries for use in EVs.

Zeta thinks it’s already found the ticket, though. It claims to offer three times the energy density of traditional lithium-ion at less than half the price. While Melissa Schilling, Zeta’s head of strategic marketing and innovation, couldn’t reveal much about Zeta’s proprietary cathode, she did tell me that it’s made of a sulfur-carbon polymer that eliminates the dreaded polysulfide shuttle effect (a claim that’s been externally verified) and allows for greater electrical conductivity. The company’s lithium-metal anode is made of carbon nanotubes, a.k.a. tiny cylinders composed of carbon atoms. The nanotubes help improve the anode’s stability, thus increasing energy density compared with traditional graphite anodes while also preventing the formation of dendrites, tiny projections on the anode that can cause the battery to break down.

Zeta’s batteries can go through about eight times more charge/discharge cycles than traditional lithium-sulfur batteries, according to the company’s figures and Manthiram’s estimation of a typical life cycle. Optimizing these batteries for EVs, though, will likely mean a much shorter cycle life, which may not be on par with what lithium-ion can do. Even so, Schilling told me, “what we’re going to beat lithium-ion on is density and cost.” The company has raised $30 million to date, and is in the midst of raising its Series B round. While Schilling couldn’t reveal the names of Zeta’s initial customers, she told me that the company is collaborating with a large automaker and heavy equipment manufacturer. Zeta has also received the same commercialization grant from the DOE as Lyten.

For its part, Lyten currently provides 25% greater energy density than top-of-the-line lithium-ion batteries, Norman told me. The company expects that soon, it will be able to offer twice the energy density at half the material cost. Lyten’s tech relies upon a so-called supermaterial, three-dimensional graphene, which it’s developing in-house. This gets combined with sulfur in the cathode to form a more conductive and stable composite material.

Norman said you can think of 3D graphene like a sponge with pore sizes “perfectly designed to hold sulfur atoms.” The graphene “gives [the sulfur] conductivity and gives it a rigid structure that doesn’t allow it to break down as easily,” he told me, meaning the battery is less likely to succumb to the polysulfide shuttle effect. Lyten’s anode is also made of energy dense lithium-metal.

Lyten hasn’t publicly revealed its battery’s cycle life, however, and in a follow-up email, Norman told me that when it comes to EV batteries, Lyten is “not yet at the cycle life we need,” though the company is “seeing 20-30% improvement in lithium-sulfur battery performance each year.” For customers using lithium-sulfur for earlier-stage applications such as drones, satellites, and two- and three-wheelers, Norman wrote that Lyten’s current cycle life “meets or very nearly meets their requirements.”

The company seems to have the money to work towards these improvements. Lyten achieved “unicorn” status last year, recording a valuation over $1 billion after closing a $200 million Series B round. It counts Stellantis and FedEx among its backers, and the Department of Defense is even funding a demonstration of Lyten’s battery tech aboard the International Space Station, where lithium-sulfur cells will be tested for use in everything from satellites to space suits.

Norman told me the company’s recent purchase of Northvolt’s old Bay Area facility represents an important step in Lyten’s path to scale. The California plant was originally designed to produce lithium-metal batteries for Cuberg, a startup Northvolt acquired in 2021 and closed down this summer. Like Lyten’s and Zeta’s, Cuberg’s batteries used a pure lithium-metal anode, while its cathode was the same old nickel-manganese-cobalt chemistry that conventional lithium-ion batteries use. With this kind of chemistry, Norman told me, it would be “very difficult to ever compete on costs.”

One of the main ways that Northvolt ultimately went wrong, Norman and Schilling agreed, is that it tried to scale standard lithium-ion tech too quickly in a price-sensitive environment. “They kind of went right to these 10, 20, 30 gigawatt-hour facilities,” Norman told me. “As they tried to scale those, they ran into a lot of manufacturing challenges and just the cost and time of trying to learn that on these huge facilities kind of bit them.” Schilling told me she thinks QuantumScape, a manufacturer of solid-state batteries for EVs, is running the same risk.

To compete with the low-cost Chinese batteries flooding the market, Norman told me domestic tech has to be demonstrably better — incremental improvements in efficiency, cost, or sustainability will not be enough. “Fundamentally, you’ve got to have a differentiated battery that customers are really dying to get their hands on,” Norman told me. But he knows that if Lyten successfully commercializes lithium-sulfur, other companies and countries will quickly get into the game.

After all, major battery giants such as LG, Samsung, SK, and Panasonic are well aware of what’s going on in the lithium-sulfur space, Manthiram told me, even if they’ve yet to make any noise about it. “They are quietly doing some work, R&D. They don’t hype it because they have a product already made,” Manthiram said, referring to the company’s widely available lithium-ion batteries. “They are also watching what academic labs are doing, what Lyten is doing, what others are doing.”

These behemoths are sure to pounce when and if the timing is right. Yet Lyten and Zeta still have the opportunity to pioneer a novel battery technology that can be fully made in America — something thus far unheard of in the battery universe.

Log in

To continue reading, log in to your account.

Create a Free Account

To unlock more free articles, please create a free account.

The Trump administration’s rollback of coal plant emissions standards means that mercury is on the menu again.

It started with the cats. In the seaside town of Minamata, on the west coast of the most southerly of Japan’s main islands, Kyushu, the cats seemed to have gone mad — convulsing, twirling, drooling, and even jumping into the ocean in what looked like suicides. Locals started referring to “dancing cat fever.” Then the symptoms began to appear in their newborns and children.

Now, nearly 70 years later, Minimata is a cautionary tale of industrial greed and its consequences. Dancing cat fever and “Minamata disease” were both the outward effects of severe mercury poisoning, caused by a local chemical company dumping methylmercury waste into the local bay. Between the first recognized case in 1956 and 2001, more than 2,200 people were recognized as victims of the pollution, which entered the population through their seafood-heavy diets. Mercury is a bioaccumulator, meaning it builds up in the tissues of organisms as it moves up the food chain from contaminated water to shellfish to small fish to apex predators: Tuna. Cats. People.

In 2013, 140 countries, including the U.S., joined the Minamata Convention, pledging to learn from the mistakes of the past and to control the release of mercury into the environment. That included, explicitly, mercury in emissions from “coal-fired power plants.” Last month, however, the U.S. Environmental Protection Agency retreated from the convention by abandoning the 2024 Mercury and Air Toxics Standards, which had reduced allowable mercury pollution from coal-fired plants by as much as 90%. Nearly all of the 219 operating coal-fired plants in the U.S. already meet the previous, looser standard, set in 2012; Trump’s EPA has argued that returning to the older rules will save Americans $670 million in regulatory compliance costs by 2037.

The rollback — while not a surprise from an administration that has long fetishized coal — came as a source of immense frustration to scientists, biologists, and activists who’ve dedicated their careers to highlighting the dangers of environmental contaminants. Nearly all human exposure to methylmercury in the United States comes from eating seafood, according to the EPA, and it’s well-documented that adding more mercury to the atmosphere will increase levels in fish, even those caught far from fenceline communities.

“Mercury is an extremely toxic metal,” Nicholas Fisher, an expert in marine pollution at Stony Brook University, told me. “It’s probably among the most toxic of all the metals, and it’s been known for centuries.” In his opinion, it’s unthinkable that there is still any question of mercury regulations making Americans safer.

Gabriel Filippelli, the executive director of the Indiana University Environmental Resilience Institute, concurred. “Mercury is not a trivial pollutant,” he told me. “Elevated mercury levels cost millions of IQ points across the country.” The EPA rollback “actually costs people brain power.”

When coal burns in a power plant, it releases mercury into the air, where it can travel great distances and eventually end up in the water. “There is no such thing as a local mercury problem,” Filippelli said. He recalled a 2011 study that looked at Indianapolis Power & Light, a former coal plant that has since transitioned to natural gas, in which his team found “a huge plume of mercury in solids downwind” of the plant, as well as in nearby rivers that were “transporting it tens of kilometers away into places where people fish and eat what they catch.”

Earthworms and small aquatic organisms convert mercury in soils and runoff into methylmercury, a highly toxic form that presents the most danger to people, children, and the fetuses of pregnant women as it moves up the food chain. Though about 70% of mercury deposited in the United States comes from outside the country — China, for example, is the second-greatest source of mercury in the Great Lakes Basin after the U.S., per the National Oceanic and Atmospheric Administration — that still leaves a significant chunk of pollution under the EPA’s control.

There is, in theory, another line of defense beyond the EPA. For recreational fishers, of whom there are nearly 60 million in the country each year, state-level advisories on which waterways are safe to fish in based on tests of methylmercury concentrations in the fish help guide decisions about what is safe to eat. Oregon, for example, advises that people not eat more than one “resident fish,” such as bass, walleye, and carp, caught from the Columbia River per week — and not eat any other seafood during that time, either. Forty-nine states have some such advisories in place; the only state that doesn’t, coal-friendly Wyoming, has refused to test its fish. One also imagines that safe waterways will start to become more limited if the coal-powered plants the Trump administration is propping up forgo the expensive equipment necessary to scrub their emissions of heavy metals.

“It’s not something where you’re going to see a dramatic change overnight,” Tasha Stoiber, a senior scientist with the Environmental Working Group, a research and advocacy nonprofit that focuses on toxic chemicals, told me. “But depending on the water body that you’re fishing in, you want to seek out state advisories.”

For people who prefer to buy their fish at the store, the Food and Drug Administration sets limits on the amount of mercury allowed in commercial seafood. But Kevin McCay, the chief operations officer at the seafood company Safe Catch, told me the FDA’s limit of 1 part per million for methylmercury is outrageously high compared with limits in the European Union and Japan. “It has to be glowing red before the FDA is actually going to do anything,” he said. (Watchdog groups have likewise warned that the hemorrhaging of civil servants from the FDA will have downstream consequences for food safety.)

McCay also told me that he “certainly” expects mercury levels in the fish to rise due to the EPA’s decision. Unlike other canned tuna companies that test batches of fish, Safe Catch drills a small test hole in every fish it buys to ensure the mercury content is well below the FDA’s limits. (Fish that are lower on the food chain, like salmon, are the safest choices, while fish at the top of the food chain, like tuna, sharks, and swordfish, are the worst.)

The obsessive oversight gives the company a front-seat view of where and how methylmercury is working its way up the food chain, and McCay worries his company could face more limited sourcing options in the coming years if policies remain friendly to coal. (An independent investigation by Consumer Reports in 2023 found that even fish sourced by an ultra-cautious company like Safe Catch contain some level of mercury. “There’s probably no actual safe amount,” McCay told me, recommending that customers should eat a diverse range of seafood to limit exposure.)

Even people who don’t eat fish should be concerned, though. That’s because, as Filippelli told me, “a lot of [contaminated] fish meal is being incorporated into pet food.”

There are no regulatory standards for mercury in pet foods. But avoiding mercury is not as simple as bypassing the tuna-flavored kibble, Sarrah M. Dunham-Cheatham, who authored a 2019 study on mercury in pet food, told me. Even many brands that don’t list fish among their ingredients contain fish meal that is high in mercury, she said.

Different species also have different sensitivities to mercury, with chimpanzees and cats being among the most sensitive. “I don’t want to be alarmist or scare people,” Dunham-Cheatham said. But because of the issues with labeling pet food, there isn’t much to be done to limit mercury intake in your pets — that is, short of dealing with the emissions on local and planetary scales. “We’re expecting there to be more emissions to the atmosphere, more deposition to aquatic environments, and therefore more mercury accumulated into proteins that will go into making the pet foods,” she said.

To Fisher, the Stony Brook professor, the Trump administration’s decision to walk back mercury restrictions makes no sense at all. The Ancient Romans understood the dangers of mercury; the dancing cats of Minamata are now seven decades behind us. “Why should we make the underlying assumption that the mercury is innocent until proven guilty?” he said.

On Qatari aluminum, floating offshore wind, and Taiwanese nuclear

Current conditions: Upstate New York and New England are facing another 2 inches of snow • A heat wave in India is sending temperatures in Gujarat beyond 100 degrees Fahrenheit • Record-breaking rain is causing flash flooding in South Australia, New South Wales, and Victoria.

The war with Iran is shocking oil and natural gas prices as the Strait of Hormuz effectively closes and Americans start paying more at the pump. “So despite the stock market overall being down, clean energy companies’ shares are soaring, right?” Heatmap’s Matthew Zeitlin wrote yesterday. “Wrong. First Solar: down over 1% on the day. Enphase: down over 3%. Sunrun: down almost 8%; Tesla: down around 2.5%.” What’s behind the slump? Matthew identified three reasons. First, there was a general selloff in the market. Second, supply chain disruptions could lead to inflation, which might lead to higher interest rates, or at the very least slow the planned cycle of cuts. Third, governments may end up trying “to mitigate spiking fuel prices by subsidizing fossil fuels and locking in supply contracts to reinforce their countries’ energy supplies,” meaning renewables “may thereby lose out on investment that might more logically flow their way.”

The U.S. liquified natural gas industry is certainly looking at boom times. U.S. developers signed sale and purchase agreements for 40 million tons per year in 2025 from planned export facilities, according to new Department of Energy data the Energy Information Administration posted. That’s the highest volume since 2022, when Russia’s invasion of Ukraine sent demand for American LNG soaring. That conflict, too, is still having its effects on global fossil fuel supplies. A Russian-flagged LNG tanker is on fire in the Mediterranean Sea as the result of a drone strike by Ukraine, The Independent reported Wednesday.

It’s not just fossil fuels. Qatari smelter Qatalum started shutting down on Tuesday as 50% shareholder Norsk Hydro issued a force majeure notice to customers. “The decision to shut down was made after the company’s gas supplier informed it of a forthcoming suspension of its gas supply,” the company said in a statement to Mining.com. QatarEnergy — which owns 51% of Qatalum’s other shareholder, Qatar Aluminum Manufacturing Co. — had previously suspended production after halting output of natural gas due to Iranian drone attacks.

Sign up to receive Heatmap AM in your inbox every morning:

Panel manufacturer Silfab Solar paused production at its South Carolina factory in Fort Mill after a chemical spill triggered a regulatory investigation. The plant accidentally spilled approximately 300 gallons of a water solution containing less than 0.3% potassium hydroxide. Experts told WCNC, the Charlotte-area NBC News affiliate, that the volume of the caustic chemical that spilled will be harmless. But the state Department of Environmental Services “asked Silfab to cease receipt of additional chemicals at their facility until an investigation is complete.” Such accidents risk political backlash at a time of heightened public health anxiety over clean energy technologies. As Heatmap’s Jael Holzman wrote last summer, the Moss Landing battery factory fire sparked a nationwide backlash.

Two-thirds of offshore wind potential is located at sites where the water is too deep for traditional turbine platforms. But the first wind farm with floating platforms only came into operation nine years ago. The largest so far, located in Norway’s stretch of the North Sea, is just under 100 megawatts. So, if completed, Spanish developer Ocean Winds’ in the United Kingdom would be by far the largest plant. The company took a step forward on the 1.5-gigawatt project when the company signed the lease agreement this week, according to OffshoreWIND.biz.

In Denmark, meanwhile, right-wing politicians are campaigning against the country’s offshore wind giant, Orsted. The country’s conservative Liberal party campaigned on divesting from the company, which claims the Danish government as its largest shareholder, back in 2022. Now, Bloomberg reported, the party is once against renewing its calls to exit Orsted after this year’s election.

Facing surging electricity demand and mounting threats of blackouts from Chinese attacks on energy imports, Taiwan is taking yet another step toward reversing its nuclear phaseout. Nearly a year after the island nation’s last reactor shut down, Taiwanese Premier Cho Jung-tai, a member of the ruling Democratic Progressive Party that has long opposed atomic energy, announced new proposals to allow the state-owned Taiwan Power Company to submit plans to restart at least two of the country’s three shuttered nuclear stations. (A fourth plant, called Lungmen, was nearly completed in the late 2010s before the DPP government canceled its construction.) The government report also said Taiwan may consider building new nuclear technologies, such as small modular reactors or fusion plants.

In June 2023, thousands of lightning strikes in heat wave-baked Quebec sparked more than 120 wildfires that ultimately scorched nearly 7,000 acres of parched forests. Lightning, in fact, starts almost 60% of wildfires. Now a Vancouver-based weather modification startup called Skyward Wildfire says it can prevent catastrophic blazes by stopping lightning strikes through cloud seeding. MIT Technology Review found some good reasons to doubt the company’s claims. But experts said preventing wildfires is cheaper than putting them out, so it may have some merit.

The attacks on Iran have not redounded to renewables’ benefit. Here are three reasons why.

The fragility of the global fossil fuel complex has been put on full display. The Strait of Hormuz has been effectively closed, causing a shock to oil and natural gas prices, putting fuel supplies from Incheon to Karachi at risk. American drivers are already paying more at the pump, despite the United States’s much-vaunted energy independence. Never has the case for a transition to renewable energy been more urgent, clear, and necessary.

So despite the stock market overall being down, clean energy companies’ shares are soaring, right?

Wrong.

First Solar: down over 1% on the day. Enphase: down over 3%. Sunrun: down almost 8%; Tesla: down around 2.5%.

Why the slump? There are a few big reasons:

Several analysts described the market action today as “risk-off,” where traders sell almost anything to raise cash. Even safe haven assets like U.S. Treasuries sold off earlier today while the U.S. dollar strengthened.

“A lot of things that worked well recently, they’re taking a big beating,” Gautam Jain, a senior research scholar at the Columbia University Center on Global Energy Policy, told me. “It’s mostly risk aversion.”

Several trackers of clean energy stocks, including the S&P Global Clean Energy Transition Index (down 3% today) or the iShares Global Clean Energy ETF (down over 3%) have actually outperformed the broader market so far this year, making them potentially attractive to sell off for cash.

And some clean energy stocks are just volatile and tend to magnify broader market movements. The iShares Global Clean Energy ETF has a beta — a measure of how a stock’s movements compare with the overall market — higher than 1, which means it has tended to move more than the market up or down.

Then there’s the actual news. After President Trump announced Tuesday afternoon that the United States Development Finance Corporation would be insuring maritime trade “for a very reasonable price,” and that “if necessary” the U.S. would escort ships through the Strait of Hormuz, the overall market picked up slightly and oil prices dropped.

It’s often said that what makes renewables so special is that they don’t rely on fuel. The sun or the wind can’t be trapped in a Middle Eastern strait because insurers refuse to cover the boats it arrives on.

But what renewables do need is cash. The overwhelming share of the lifetime expense of a renewable project is upfront capital expenditure, not ongoing operational expenditures like fuel. This makes renewables very sensitive to interest rates because they rely on borrowed money to get built. If snarled supply chains translate to higher inflation, that could send interest rates higher, or at the very least delay expected interest rate cuts from central banks.

Sustained inflation due to high energy prices “likely pushes interest rate cuts out,” Jain told me, which means higher costs for renewables projects.

While in the long run it may make sense to respond to an oil or natural gas supply shock by diversifying your energy supply into renewables, political leaders often opt to try to maintain stability, even if it’s very expensive.

“The moment you start thinking about energy security, renewables jump up as a priority,” Jain said. “Most countries realize how important it is to be independent of the global supply chain. In the long term it works in favor of renewables. The problem is the short term.”

In the short term, governments often try to mitigate spiking fuel prices by subsidizing fossil fuels and locking in supply contracts to reinforce their countries’ energy supplies. Renewables may thereby lose out on investment that might more logically flow their way.

The other issue is that the same fractured supply chain that drives up oil and gas prices also affects renewables, which are still often dependent on imports for components. “Freight costs go up,” Jain said. “That impacts clean energy industry more.”

As for the Strait of Hormuz, Trump said the Navy would start escorting ships “as soon as possible.”