You’re out of free articles.

Log in

To continue reading, log in to your account.

Create a Free Account

To unlock more free articles, please create a free account.

Sign In or Create an Account.

By continuing, you agree to the Terms of Service and acknowledge our Privacy Policy

Welcome to Heatmap

Thank you for registering with Heatmap. Climate change is one of the greatest challenges of our lives, a force reshaping our economy, our politics, and our culture. We hope to be your trusted, friendly, and insightful guide to that transformation. Please enjoy your free articles. You can check your profile here .

subscribe to get Unlimited access

Offer for a Heatmap News Unlimited Access subscription; please note that your subscription will renew automatically unless you cancel prior to renewal. Cancellation takes effect at the end of your current billing period. We will let you know in advance of any price changes. Taxes may apply. Offer terms are subject to change.

Subscribe to get unlimited Access

Hey, you are out of free articles but you are only a few clicks away from full access. Subscribe below and take advantage of our introductory offer.

subscribe to get Unlimited access

Offer for a Heatmap News Unlimited Access subscription; please note that your subscription will renew automatically unless you cancel prior to renewal. Cancellation takes effect at the end of your current billing period. We will let you know in advance of any price changes. Taxes may apply. Offer terms are subject to change.

Create Your Account

Please Enter Your Password

Forgot your password?

Please enter the email address you use for your account so we can send you a link to reset your password:

With its Orchard One project in Wyoming, Spiritus thinks it can capture carbon from the air for less than $100 per ton.

Pretty much every startup that’s building machines to suck carbon dioxide from the atmosphere and stash it underground has claimed it will be able to get its costs down to less than $100 per ton — eventually.

But a new contender in the race, a San Francisco-based company called Spiritus, is making a compelling case that it could get there faster. On Tuesday, Spiritus announced plans to build its first direct air capture, or “DAC” project in central Wyoming, nicknamed Orchard One. The company will start small but ultimately wants to expand the facility to capture 2 million tons of CO2 per year.

Achieving that scale at the sub-$100 price point would be game-changing for direct air capture, which is still far too expensive to be a viable climate solution. Most companies in the field are cagey about revealing their current costs, but the industry-average price is believed to be between $600 and $1,000 per ton.

So what makes Spiritus different? Here are three reasons we’ll be keeping an eye on the company.

Spiritus’ project will not look anything like the industrial-style shipping containers full of fans that have become the defining form factor for DAC plants. The company’s central innovation is a squishy white ball that founder Charles Cadieu describes as an artificial lung.

“While it looks kind of simple, it's actually a breakthrough material that has an incredible amount of surface area,” he told me over Zoom, while holding one up and squeezing it like a stress relief toy. “And it has holes all over it that allow the CO2 to go right inside.” Though it’s about the size of a tennis ball, its branch-like interior structure has a surface area equivalent to a tennis court, he said.

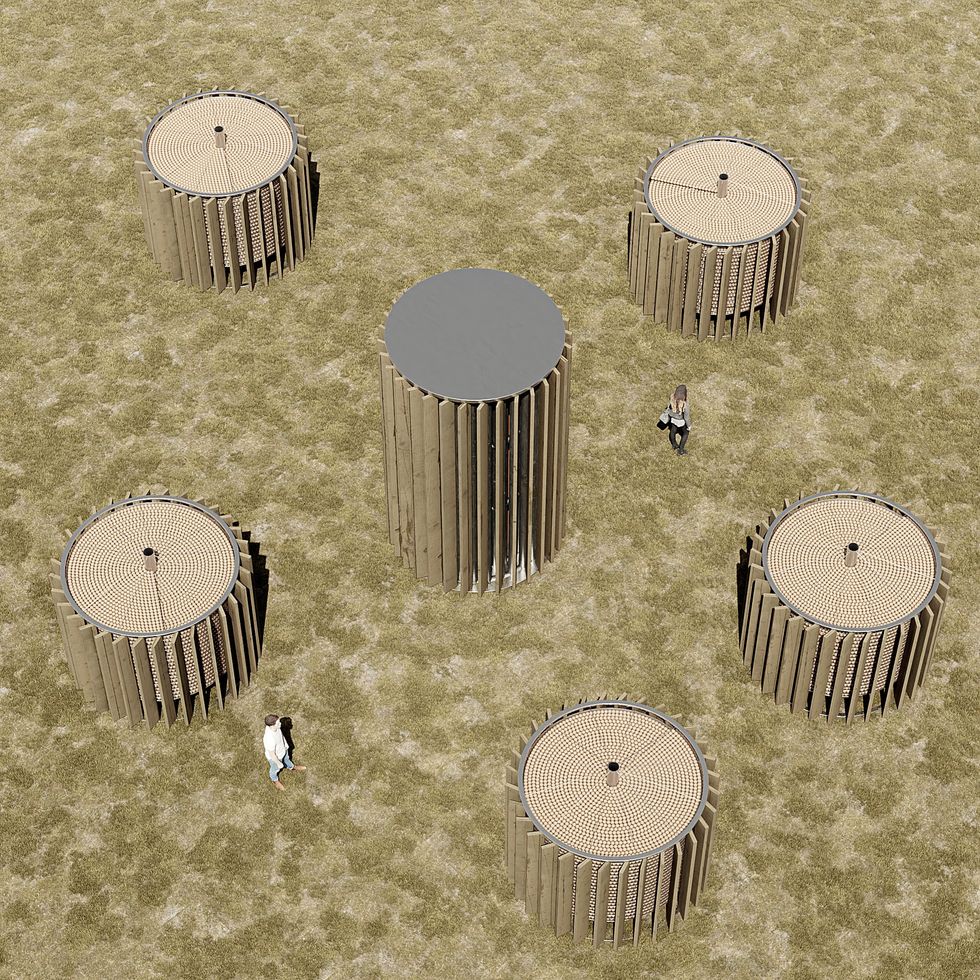

The ball is made of a proprietary material that selectively attracts CO2 molecules. As air wafts through it, CO2 sticks to its interior surfaces like a magnet. Spiritus will manufacture millions of these balls, lay them out on trays, and stack the trays on tree-like rigs — hence the name Orchard One. Concept images depict a small colony of cylindrical structures that will house the trays, almost like miniature Wilco towers, sprouting up amid the Wyoming sagebrush.

After a few hours exposed to the elements, the balls, which Spiritus prefers to call “fruits,” will be full of carbon. The company will then transfer them to a separate chamber and apply heat, causing them to expel the CO2. That stream of carbon will be compressed and delivered to an underground CO2 storage well, while the fruits will be returned to their towers to live the same day over and over again.

Though the concept is somewhat whimsical, the company is making serious claims about its cost and performance. The biggest expenses for direct air capture projects are materials and energy, and Spiritus has made significant improvements on both fronts. Cadieu told me they can manufacture their sorbent for a tenth of the cost of other, “state of the art sorbents that are out there today,” and that “furthermore, it’s 10 times as effective” at capturing carbon. In other words, Spiritus claims it can capture more carbon from the air at a time, using fewer, cheaper materials than other methods.

Since the capture part of the process is passive, the company doesn’t need to use energy-intensive fans to filter the air. Also, the temperature required for the second step, where heat is applied to the balls to release the CO2, is lower than 212 degrees Fahrenheit — low enough to be generated using electricity. Cadieu said Spiritus plans to procure energy from renewable sources so that the entire process has net-negative greenhouse gas emissions.

Spiritus isn’t the only company with a low-cost sorbent and passive capture method. Notably, the DAC process pioneered by Heirloom, which opened its first commercial-scale plant in California last year, shares those features, but it requires much higher temperatures — 1,650 degree Fahrenheit — to isolate the captured carbon.

Though Spiritus still has to prove this all works as promised in the real world, the company has earned an early vote of confidence from Frontier, the coalition of tech companies with a $1 billion fund to help carbon removal scale. Last year, Frontier paid Spiritus $500,000 to buy its first 713 removal credits, each of which represents a ton of carbon that will be permanently sequestered underground. (The money is more of a development grant than anything indicative of the company’s costs.)

“We look for companies that learn and iterate quickly, and we were impressed by what we saw from Spiritus when they applied,” Joanna Klitzke, the procurement and ecosystem strategy lead at Frontier, told me. “And actually, since then, the team has made really strong improvements and steady progress on both their sorbent and their process performance.”

According to the company’s application for funding from Frontier, Spiritus estimates that for the first phase of Orchard One — when the project is capturing less than 2,000 tons per year — its levelized cost per ton of carbon will be about $149, not including the cost of burying the carbon underground. By phase two, at a scale of about 500,000 tons per year, it expects to get that cost down to less than $100. And by phase three, at the full scale of 2 million tons per year, it expects to achieve sub-$75 capture.

Cadieu told me the company is already in talks with large buyers to purchase carbon removal from Orchard One for “far less” than the per-ton price Frontier paid.

Spiritus doesn’t expect to have phase one of the project up and running until 2026. But it already has a running start. The land lease is locked down, the underground pore space where the company will inject the captured carbon has been identified, and a monitoring well is already scheduled to be drilled — according to its Frontier application.

Wyoming has proved to be a relatively welcoming place for this emerging industry. Orchard One is joining another direct air capture plant already under development in the southwest part of the state called Project Bison. Cadieu gave three reasons the project landed there: There’s a local workforce with relevant experience from the oil and gas industry, the state has the ideal geology to trap the captured carbon underground, and Wyoming has been at the forefront of developing clear regulations for carbon sequestration. It was one of the first states to gain authorization from the Environmental Protection Agency to permit carbon storage wells, and as of December had already permitted three. Another advantage in Wyoming is abundant renewable energy from wind farms.

Spiritus has yet to reveal exactly where in Wyoming Orchard One will be built, but Cadieu told me he has been in close contact with officials at the town, county, and state levels, and that the reception has been enthusiastic. He said the project will create “hundreds of jobs during construction” and “many dozens of jobs” when the facility is operating, and that the company will deliver a portion of its profits back into the community.

Log in

To continue reading, log in to your account.

Create a Free Account

To unlock more free articles, please create a free account.

The administration has yet to publish formal documentation of its decision, leaving several big questions unanswered.

President Trump announced on Thursday that he was repealing the Environmental Protection Agency’s scientific determination that greenhouse gases are dangerous to human health and the natural world.

The signal move would hobble the EPA’s ability to limit heat-trapping pollution from cars, trucks, power plants, and other industrial facilities. It is the most aggressive attack on environmental regulation that the president and his officials have yet attempted.

The move, which was first proposed last summer, has major legal implications. But its importance is also symbolic: It brings the EPA’s official view of climate change much closer to President Trump’s false but long-held claim that anthropogenic global warming — which scientists have long affirmed as a major threat to public health and the environment — is in fact a “con job,” “a hoax,” and a “scam.”

While officials in the first Trump administration frequently sought to undermine climate regulation, arguing that the government’s climate rules were unnecessary or a waste of time and money, they did not formally try to undo the agency’s scientific determination that heat-trapping pollution was dangerous.

The move is only the most recent of a long list of attacks on environmental protections — including the partial rollback of the country’s first climate law, the Inflation Reduction Act, enacted last summer — that Trump and congressional Republicans have overseen since taking office last January.

The repeal has few near-term implications for utilities, clean energy companies, or automakers because the Trump administration has already suspended rules limiting air pollution from vehicles and the power sector. But it could shape the long-term direction of American climate and energy policy.

Several environmental and public health organizations, including the American Lung Association and the Environmental Defense Fund, have vowed to challenge the move in court.

If the Supreme Court eventually rules in favor of the Trump administration, then it would hamstring the ability of any future president — Republican or Democrat — to use the EPA to slow climate change or limit greenhouse gas pollution. The EPA has not yet published the legal documents formalizing the repeal.

Here is what we know — and don’t know — about the repeal for now:

Startups Airloom Energy and Radia looked at the same set of problems and came up with very different solutions.

You’d be forgiven for assuming that wind energy is a technologically stagnant field. After all, the sleek, three-blade turbine has defined the industry for nearly half a century. But even with over 1,000 gigawatts of wind generating capacity installed worldwide, there’s a group of innovators who still see substantial room for improvement.

The problems are myriad. There are places in the world where the conditions are too windy and too volatile for conventional turbines to handle. Wind farms must be sited near existing transportation networks, accessible to the trucks delivering the massive components, leaving vast areas with fantastic wind resources underdeveloped. Today’s turbines have around 1,500 unique parts, and the infrastructure needed to assemble and stand up a turbine’s multi-hundred-foot tower and blades is expensive— giant cranes don’t come cheap.

“We’ve only really ever tried one type of technology,” Neal Rickner, the CEO of the wind power startup Airloom Energy, told me. Now, he’s one of a few entrepreneurs trying a new approach.

Airloom’s system uses much-shorter vertical blades attached to an oval track that resembles a flat rollercoaster — no climbs or drops, just a horizontal loop composed of 58 unique parts. Wind propels the blades around the track, turning a vertical shaft that’s connected to an electricity-producing generator. That differs from conventional turbines, which spin on a vertical plane around a horizontal shaft, like a ferris wheel.

The system is significantly lower to the ground than today’s turbines and has the ability to capture wind from any direction, unlike conventional turbines, allowing for deployment in areas with shifting wind patterns. It promises to be mass manufacturable, cheap, and simple to transport and install, opening up the potential to build systems in a wider variety of geographies — everywhere from airports to remote or even mountainous regions.

Airloom’s CTO, Andrew Streett, brings a background in drone tech that Rickner said helped shape the architecture of Airloom’s blades. “It’s all known tech. And it’s not completely off the shelf, but Andrew’s done it on 17 other platforms,” he told me. Rickner himself spent years at GoogleX working on Makani, a now-defunct wind energy project that attempted to commercialize an airborne wind energy system. The concept involved attaching rotors to autonomous kites, which flew in high-altitude loops to capture wind energy.

That system ultimately proved too complicated, something Airloom’s founder Robert Lumley warned Rickner about a decade ago at an industry conference. As Rickner recalls, he essentially told him, “all of that flying stuff is too complicated. Put all that physics — which is great — put it on the ground, on a rail.” Rickner took the lesson to heart, and when Lumley recruited him to join Airloom’s team a few years ago, he said it felt like an ideal chance to apply all the knowledge he’d accumulated “around what it takes to bring a novel wind technology to a very stodgy market.”

Indeed, the industry has proven difficult to disrupt. While Airloom was founded in 2014, the startup is still in its early stages, though it’s attracted backing from some climate sector heavyweights. Lowercarbon Capital led its $7.5 million seed round in 2024, which also included participation from Breakthrough Energy Ventures. The company also secured $5 million in matching funds from the state of Wyoming, where it’s based, and a $1.25 million contract with the Department of Defense.

Things are moving now. In the coming months, Airloom is preparing to bring its pilot plant online in Wyoming, closely followed by a commercial demo. Rickner told me the plan is to begin construction on a commercial facility by July 4, the deadline for wind to receive federal tax credits.

“If you could just build wind without gigantic or heavy industrial infrastructure — cranes and the like —- you will open up huge parts of the world,” Rickner told me, citing both the Global South and vast stretches of rural America as places where the roads, bridges, cranes, and port infrastructure may be insufficient for transporting and assembling conventional turbines. While modern onshore installations can exceed 600 feet from the tower’s base to the blade’s tip, Airloom’s system is about a fifth that height. Its nimble assembly would also allow turbines to be sited farther from highways, potentially enabling a more “out of sight, out of mind” attitude among residents and passersby who might otherwise resist such developments.

The company expects some of its first installations to be co-located with — you guessed it — data centers, as tech giants are increasingly looking to circumvent lengthy grid interconnection queues by sourcing power directly from onsite renewables, an option Rickner said wasn’t seriously discussed until recently.

Even considering Trump’s cuts to federal incentives for wind, “I’d much rather be doing Airloom today than even a year ago,” Rickner told me. “Now, with behind-the-meter, you’ve got different financing options. You’ve got faster buildout timelines that actually meet a venture company, like Airloom. You can see it’s still a tough road, don’t get me wrong. But a year ago, if you said we’re just going to wait around seven years for the interconnection queue, no venture company is going to survive that.”

It’s certainly not the only company in the sector looking to benefit from the data center boom. But I was still surprised when Rickner pointed out that Airloom’s fundamental value proposition — enabling wind energy in more geographies — is similar to a company that at first glance appears to be in a different category altogether: Radia.

Valued at $1 billion, this startup plans to make a plane as long as a football field to carry blades roughly 30% to 40% longer than today’s largest onshore models. Because larger blades mean more power, Radia’s strategy could make wind energy feasible in low-wind regions or simply boost output where winds are strong. And while the company isn’t looking to become a wind developer itself, “if you look at their pitch, it is the Airloom pitch,” Rickner told me.

Will Athol, Radia’s director of business development, told me that by the time the company was founded in 2016, “it was becoming clear that ground-based infrastructure — bridges, tunnels, roads, that kind of thing — was increasingly limiting where you can deploy the best turbines,” echoing Airloom’s sentiments. So competitors in the wind industry teamed up, requesting logistics input from the aviation industry. Radia responded, and has since raised over $100 million as it works to achieve its first flight by 2030.

Hopefully by that point, the federal war on wind will be a thing of the past. “We see ourselves and wind energy as a longer term play,” Athol told me. Though he acknowledged that these have certainly been “eventful times for the wind industry” in the U.S., there’s also a global market eager for this tech. He sees potential in regions such as India and North Africa, where infrastructure challenges have made it tough to deploy large-scale turbines.

Neither Radia nor Airloom thinks its approach will render today’s turbines obsolete, or that other renewable resources will be completely displaced. “I think if you look at most utilities, they want a mix,” Rickner said. But he’s still pretty confident in Airloom’s potential to seriously alter an industry that’s long been considered mature and constrained to incremental gains.

“When Airloom is 100% successful,” he told me, “we will take a huge chunk of market share.”

On electrolyzers’ decline, Anthropic’s pledge, and Syria’s oil and gas

Current conditions: Warmer air from down south is pushing the cold front in Northeast back up to Canada • Tropical Cyclone Gezani has killed at least 31 in Madagascar • The U.S. Virgin Islands are poised for two days of intense thunderstorms that threaten its grid after a major outage just days ago.

Back in November, Democrats swept to victory in Georgia’s Public Service Commission races, ousting two Republican regulators in what one expert called a sign of a “seismic shift” in the body. Now Alabama is considering legislation that would end all future elections for that state’s utility regulator. A GOP-backed bill introduced in the Alabama House Transportation, Utilities, and Infrastructure Committee would end popular voting for the commissioners and instead authorize the governor, the Alabama House speaker, and the Alabama Senate president pro tempore to appoint members of the panel. The bill, according to AL.com, states that the current regulatory approach “was established over 100 years ago and is not the best model for ensuring that Alabamians are best-served and well-positioned for future challenges,” noting that “there are dozens of regulatory bodies and agencies in Alabama and none of them are elected.”

The Tennessee Valley Authority, meanwhile, announced plans to keep two coal-fired plants operating beyond their planned retirement dates. In a move that seems laser-targeted at the White House, the federally-owned utility’s board of directors — or at least those that are left after President Donald Trump fired most of them last year — voted Wednesday — voted Wednesday to keep the Kingston and Cumberland coal stations open for longer. “TVA is building America’s energy future while keeping the lights on today,” TVA CEO Don Moul said in a statement. “Taking steps to continue operations at Cumberland and Kingston and completing new generation under construction are essential to meet surging demand and power our region’s growing economy.”

Secretary of the Interior Doug Burgum said the Trump administration plans to appeal a series of court rulings that blocked federal efforts to halt construction on offshore wind farms. “Absolutely we are,” the agency chief said Wednesday on Bloomberg TV. “There will be further discussion on this.” The statement comes a week after Burgum suggested on Fox Business News that the Supreme Court would break offshore wind developers’ perfect winning streak and overturn federal judges’ decisions invalidating the Trump administration’s orders to stop work on turbines off the East Coast on hotly-contested national security, environmental, and public health grounds. It’s worth reviewing my colleague Jael Holzman’s explanation of how the administration lost its highest profile case against the Danish wind giant Orsted.

Thyssenkrupp Nucera’s sales of electrolyzers for green hydrogen projects halved in the first quarter of 2026 compared to the same period last year. It’s part of what Hydrogen Insight referred to as a “continued slowdown.” Several major projects to generate the zero-carbon fuel with renewable electricity went under last year in Europe, Australia, and the United States. The Trump administration emphasized the U.S. turn away from green hydrogen by canceling the two regional hubs on the West Coast that were supposed to establish nascent supply chains for producing and using green hydrogen — more on that from Heatmap’s Emily Pontecorvo. Another potential drag on the German manufacturer’s sales: China’s rise as the world’s preeminent manufacturer of electrolyzers.

Sign up to receive Heatmap AM in your inbox every morning:

The artificial intelligence giant Anthropic said Wednesday it would work with utilities to figure out how much its data centers were driving up electricity prices and pay a rate high enough to avoid passing the costs onto ratepayers. The announcement came as part of a multi-pronged energy strategy to ease public concerns over its data centers at a moment when the server farms’ effect on power prices and local water supplies is driving a political backlash. As part of the plan, Anthropic would cover 100% of the costs of upgrading the grid to bring data centers online, and said it would “work to bring net-new power generation online to match our data centers’ electricity needs.” Where that isn’t possible, the company said it would “work with utilities and external experts to estimate and cover demand-driven price effects from our data centers.” The maker of ChatGPT rival Claude also said it would establish demand response programs to power down its data centers when demand on the grid is high, and deploy other “grid optimization” tools.

“Of course, company-level action isn’t enough. Keeping electricity affordable also requires systemic change,” the company said in a blog post. “We support federal policies — including permitting reform and efforts to speed up transmission development and grid interconnection — that make it faster and cheaper to bring new energy online for everyone.”

Syria’s oil reserves are opening to business, and Western oil giants are in line for exploration contracts. In an interview with the Financial Times, the head of the state-owned Syrian Petroleum Company listed France’s TotalEnergies, Italy’s Eni, and the American Chevron and ConocoPhillips as oil majors poised to receive exploration licenses. “Maybe more than a quarter, or less than a third, has been explored,” said Youssef Qablawi, chief executive of the Syrian Petroleum Company. “There is a lot of land in the country that has not been touched yet. There are trillions of cubic meters of gas.” Chevron and Qatar’s Power International Holding inked a deal just last week to explore an offshore block in the Mediterranean. Work is expected to begin “within two months.”

At the same time, Indonesia is showing the world just how important it’s become for a key metal. Nickel prices surged to $17,900 per ton this week after Indonesia ordered steep cuts to protection at the world’s biggest mine, highlighting the fast-growing Southeast Asian nation’s grip over the global supply of a metal needed for making batteries, chemicals, and stainless steel. The spike followed Jakarta’s order to cut production in the world’s biggest nickel mine, Weda Bay, to 12 million metric tons this year from 42 million metric tons in 2025. The government slashed the nationwide quota by 100 million metric tons to between 260 million and 270 million metric tons this year from 376 million metric tons in 2025. The effect on the global price average showed how dominant Indonesia has become in the nickel trade over the past decade. According to another Financial Times story, the country now accounts for two-thirds of global output.

The small-scale solar industry is singing a Peter Tosh tune: Legalize it. Twenty-four states — funny enough, the same number that now allow the legal purchase of marijuana — are currently considering legislation that would allow people to hook up small solar systems on balconies, porches, and backyards. Stringent permitting rules already drive up the cost of rooftop solar in the U.S. But systems small enough for an apartment to generate some power from a balcony have largely been barred in key markets. Utah became the first state to vote unanimously last year to pass a law allowing residents to plug small solar systems straight into wall sockets, providing enough electricity to power a laptop or small refrigerator, according to The New York Times.