You’re out of free articles.

Log in

To continue reading, log in to your account.

Create a Free Account

To unlock more free articles, please create a free account.

Sign In or Create an Account.

By continuing, you agree to the Terms of Service and acknowledge our Privacy Policy

Welcome to Heatmap

Thank you for registering with Heatmap. Climate change is one of the greatest challenges of our lives, a force reshaping our economy, our politics, and our culture. We hope to be your trusted, friendly, and insightful guide to that transformation. Please enjoy your free articles. You can check your profile here .

subscribe to get Unlimited access

Offer for a Heatmap News Unlimited Access subscription; please note that your subscription will renew automatically unless you cancel prior to renewal. Cancellation takes effect at the end of your current billing period. We will let you know in advance of any price changes. Taxes may apply. Offer terms are subject to change.

Subscribe to get unlimited Access

Hey, you are out of free articles but you are only a few clicks away from full access. Subscribe below and take advantage of our introductory offer.

subscribe to get Unlimited access

Offer for a Heatmap News Unlimited Access subscription; please note that your subscription will renew automatically unless you cancel prior to renewal. Cancellation takes effect at the end of your current billing period. We will let you know in advance of any price changes. Taxes may apply. Offer terms are subject to change.

Create Your Account

Please Enter Your Password

Forgot your password?

Please enter the email address you use for your account so we can send you a link to reset your password:

It’s been just over a week since one of the 350-foot-long blades of a wind turbine off the Massachusetts coast unexpectedly broke off, sending hunks of fiberglass and foam into the waters below. As of Wednesday morning, cleanup crews were still actively removing debris from the water and beaches and working to locate additional pieces of the blade.

The blade failure quickly became a crisis for residents of Nantucket, where debris soon began washing up on the island’s busy beaches. It is also a PR nightmare for the nascent U.S. offshore wind industry, which is already on the defensive against community opposition and rampant misinformation about its environmental risks and benefits.

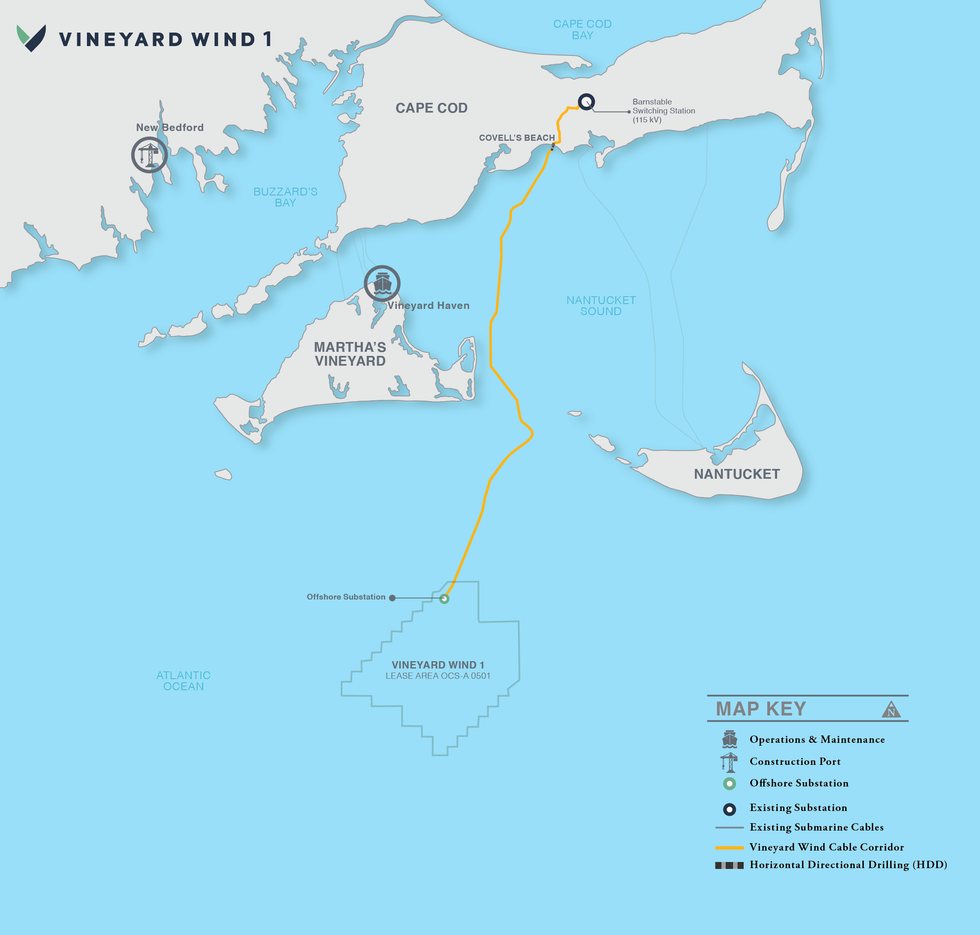

The broken turbine is part of Vineyard Wind 1, which is being developed by Avangrid and Copenhagen Infrastructure Partners. The project was still under construction when the breakage occurred, but it was already the largest operating offshore wind farm in the US, with ten turbines sending power to the New England Grid as of June. The plan is to bring another 52 online, which will produce enough electricity to power more than 400,000 homes. Now both installation and power generation have been paused while federal investigators look into the incident.

There’s still a lot we don’t know about why this happened, what the health and safety risks are, and what it means for this promising clean energy solution going forward. But here’s everything we’ve learned so far.

Vineyard Wind

On the evening of Saturday, July 13, Vineyard Wind received an alert that there was a problem with one of its turbines. The equipment contains a “delicate sensoring system,” CEO Klaus Moeller told the Nantucket Select Board during a public meeting last week. Though he did not describe what the alert said, he added that “one of the blades was broken and folded over.” Later at the meeting, a spokesperson for GE Vernova, which manufactured and installed the turbines, said that “blade vibrations” had been detected. About a third of the blade, or roughly 120 feet, fell into the water.

Two days later, Vineyard Wind contacted the town manager in Nantucket to explain that modeling showed the potential for debris from the blade to travel toward the island. Sure enough, fiberglass shards and other scraps began washing up on shore the next day, and all beaches on the island’s south shore were quickly closed to the public.

On Thursday morning, another large portion of the damaged blade detached and fell into the ocean. Monitoring and recovery crews continued to find debris throughout the area over the weekend. The beaches have since reopened, but visitors have been advised to wear shoes and leave their pets at home as cleanup continues.

During GE’s second quarter earnings call on July 24, GE Vernova CEO Scott Strazik and Vice President of Investor Relations Michael Lapides said the company had identified a “material deviation” as the cause of the accident, and that the company is continuing to work on a "root cause analysis" to get to the bottom of how said deviation happened in the first place.

The turbine was one of GE’s Haliade-X 13-megawatt turbines, which are manufactured in Gaspé, Canada, and it was still undergoing post-installation testing by GE when the failure occurred — that is, it was not among those sending power to the New England grid. This was actually the second issue the company has had at this particular turbine site. One of the original blades destined for the site was damaged during the installation process, and the one that broke last week was a replacement, Craig Gilvard, Vineyard Wind’s communications director, told the New Bedford Light.

By Vineyard Wind’s account at the meeting last week, the accident triggered an automatic shut down of the system and activated the company’s emergency response plan, which included immediately notifying the U.S. Coast Guard, the federal Bureau of Safety and Environmental Enforcement, and regional emergency response committees.

Moeller, the CEO, said during the meeting that the company worked with the Coast Guard to immediately establish a 500 meter “safety zone” around the turbine and to send out notices to mariners. According to the Coast Guard’s notice log, however, the safety zone went into effect three days later. In response to my questions, the Coast Guard confirmed that the zone was established around 8pm that night and announced to mariners over radio broadcast.

Two days after the turbine broke, on Monday, Vineyard Wind contacted the National Oceanic and Atmospheric Administration for aid in modeling where the turbine debris would travel in the water. The agency estimated pieces would likely make landfall in Nantucket that day. Vineyard Wind put out a press release about the accident and subsequently contacted the Nantucket town manager. At the Nantucket Select Board meeting last week, Moeller said the company followed regulatory protocols but that there was “really no excuse” for how long it took to inform the public, and said, “we want to move much quicker and make sure that we learn from this.”

The Interior Department’s Bureau of Safety and Environmental Enforcement has ordered the company to cease all power production and installation activities until it can determine whether this was an isolated incident or affects other turbines.

By Tuesday, Vineyard Wind said it had deployed two small teams to Nantucket in addition to hiring a local contractor to remove debris on the island. The company later said it would “increase its local team to more than 50 employees and contractors dedicated to beach clean-up and debris recovery efforts.”

GE Vernova is responsible for recovering offshore debris and has not published any public statements about the effort. In response to a list of questions, a GE Vernova spokesperson said, “We continue to work around the clock to enhance mitigation efforts in collaboration with Vineyard Wind and all relevant state, local and federal authorities. We are working with urgency to complete our root cause analysis of this event.”

There have been no reported injuries as a result of the accident.

Vineyard Wind and GE Vernova have stressed that the debris are “not toxic.” At the Select Board meeting, GE’s executive fleet engineering director Renjith Viripullan said that the blade is made of fiberglass, foam, and balsa wood. It is bonded together using a “bond paste,” he said, and likened the blade construction to that of a boat. “That's the correlation we need to think about,” he said.

One of the board members asked if there was any risk of PFAS contamination as a result of the accident. Viripullan said he would need to “take that question back” and follow up with the answer later. (This was one of the questions I asked GE, but the company did not respond to it.)

That being said, the debris poses some dangers. Photos of cleanup crews posted to the Harbormaster’s Facebook page show workers wearing white hazmat suits. Vineyard Wind said “members of the public should avoid handling debris as the fiber-glass pieces can be sharp and lead to cuts if handled without proper gloves.”

Though members of the public raised concerns at the meeting and to the press that fiberglass fragments in the ocean threaten marine life and public health, it is not yet clear how serious the risks are, and several efforts are underway to further assess them. Vineyard Wind is developing a water quality testing plan for the island and setting up a process for people to file claims. GE hired a design and engineering firm to conduct an environmental assessment, which it will present at a Nantucket Select Board meeting later this week. The Massachusetts Department of Environmental Protection has requested information from the companies about the makeup of the debris to evaluate risks, and the Department of Fish and Game is monitoring for impacts to the local ecosystem.

As of last Wednesday morning, Vineyard Wind had collected “approximately 17 cubic yards of debris, enough to fill more than six truckloads, and several larger pieces that washed ashore.” It is not yet known what fraction of the turbine that fell off has been recovered. Vineyard Wind did not respond to a request for the latest numbers in time for publication, but I’ll update this piece if I get a response.

Yes. In May, a blade on the same model of turbine, the GE Haliade-X, sustained damage at a wind farm being installed off the coast of England called Dogger Bank. At the Nantucket Select Board meeting, a spokesperson for GE said the Dogger Bank incident was “an installation issue specific to the installation of that blade” and that “we don’t think there’s a connection between that installation issue and what we saw here.” Executives emphasized this point during the earnings call and chalked up the Dogger Bank incident to “an installation error out at sea.”

Several blades have also broken off another GE turbine model dubbed the Cypress at wind farms in Germany and Sweden. After the most recent incident in Germany last October, the company used similar language, telling reporters that it was working to “determine the root cause.”

A “company source with knowledge of the investigations” into the various incidents recently told CNN that “there were different root causes for the damage, including transportation, handling, and manufacturing deviations.”

GE Vernova’s stock price fell nearly 10% last Wednesday.

The backlash was swift. Nantucket residents immediately wrote to Nantucket’s Select Board to ask the town to stop the construction of any additional offshore wind turbines. “I know it's not oil, but it's sharp and maybe toxic in other ways,” Select Board member Dawn Holgate told company executives at the meeting last week. “We're also facing an exponential risk if this were to continue because many more windmills are planned to be built out there and there's been a lot of concern about that throughout the community.”

The Select Board plans to meet in private on Tuesday night to discuss “potential litigation by the town against Vineyard Wind relative to recovery costs.”

“We expect Vineyard Wind will be responsible for all costs and associated remediation efforts incurred by the town in response to the incident,” Elizabeth Gibson, the Nantucket town manager said during the meeting last week.

The Aquinnah Wampanoag tribe is also calling for a moratorium on offshore wind development and raised concerns about the presence of fiberglass fragments in the water.

On social media, anti-wind groups throughout the northeast took up the story as evidence that offshore wind is “not green, not clean.” Republican state representatives in Massachusetts cited the incident as a reason for opposing legislation to expedite clean energy permitting last week. Fox News sought comment from internet personality and founder of Barstool Sports David Portnoy, who owns a home on Nantucket and said the island had been “ruined by negligence.” The Texas Public Policy Foundation, a nonprofit funded by oil companies and which is backing a lawsuit against Vineyard Wind, cited the incident as evidence that the project is harming local fishermen. The First Circuit Court of Appeals is set to hear oral arguments on the case this Thursday.

Meanwhile, environmental groups supportive of offshore wind tried to do damage control for the industry. “Now we must all work to ensure that the failure of a single turbine blade does not adversely impact the emergence of offshore wind as a critical solution for reducing dependence on fossil fuels and addressing the climate crisis,” the Sierra Club’s senior advisor for offshore wind, Nancy Pyne, wrote in a statement. “Wind power is one of the safest forms of energy generation.”

This story was last updated July 24 at 3:15 p.m. The current version contains new information and corrects the location where the turbine blades are produced. With assistance from Jael Holzman.

Log in

To continue reading, log in to your account.

Create a Free Account

To unlock more free articles, please create a free account.

The battery recycling company announced a $425 million Series E round after pivoting to power data centers.

Amidst a two year-long slump in lithium prices, the Nevada-based battery recycling company Redwood Materials announced last summer that it had begun a new venture focused on grid-scale energy storage. Today, it’s clear just how much that bet has paid off.

The company announced a $425 million round of Series E funding for the new venture, known as Redwood Energy. That came from some big names in artificial intelligence, including Google and Nvidia’s venture capital arm, NVentures. This marks the final close of the funding round, increasing the total from $350 million announced in October.

Redwood Energy adapts the company’s original mission — breaking down spent batteries to recover, refine, and resell critical minerals — to suit the data center revolution. Instead of merely extracting battery materials, the company can now also repurpose electric vehicle batteries that still have some life left in them as energy storage solutions for AI data centers, allowing Redwood to get value from the battery throughout its lifecycle.

“Regardless of where lithium prices are, if we can put [a lithium-ion battery] in a large-scale energy storage system, it can have a lot more value before we break it down into critical materials,” Claire McConnell, Redwood’s new VP of business development for energy storage, told me.

Over the past 12 to 18 months, she explained that the company had started to receive more and more used electric vehicle battery packs “in better condition than we initially anticipated.” Given the substantial electricity load growth underway, McConnell said the company saw it as “perfect moment” to “develop something that could be really unique for that market.”

At the time of Redwood Energy’s launch last June, the company announced that it had stockpiled over a gigawatt-hour of used EV batteries, with an additional 5 gigawatt-hours expected over the following year. Its first microgrid pilot is already live and generating revenue in Sparks, Nevada, operating in partnership with the data center owner and operator Crusoe Energy. That project is off-grid, supplying solar-generated electricity directly to Crusoe’s data center. Future projects could be grid-connected though, storing energy when prices are low and dispatching it when there are spikes in demand.

The company also isn’t limiting itself to used battery packs, McConnell told me. Plenty of manufacturers, she said, are sitting on a surplus of new batteries that they’re willing to offload to Redwood. The potential reasons for that glut are easy to see: already-slower-than-expected EV adoption compounded by Trump’s rollback of incentives has left many automakers with lower than projected EV sales. And even in the best of times, automakers routinely retool their product lines, which could leave them with excess inventory from an older model.

While McConnell wouldn’t reveal what percent of packs are new, she did tell me they make up a “pretty meaningful percentage of our inventory right now,” pointing to a recently announced partnership with General Motors meant to accelerate deployment of both new and used battery packs for energy storage.

While Redwood isn’t abandoning its battery recycling roots, this shift in priorities toward data center energy storage comes after a tough few years for the battery recycling sector overall. By last June, lithium prices had fallen precipitously from their record highs in 2022, making mineral recycling far less competitive. Then came Trump’s cuts to consumer electric vehicle incentives, further weakening demand. On top of that, the rise of lithium-iron phosphate batteries — which now dominate the battery storage sector and are increasingly common in EVs — have reduced the need for nickel and cobalt in particular, as they’re not a part of this cheaper battery chemistry.

All this helped create the conditions for the bankruptcy of one of Redwood’s main competitors, Li-Cycle, in May 2025. The company went public via a SPAC merger in 2021, aiming to commercialize its proprietary technique for shredding whole lithium-ion battery packs at once. But it ultimately couldn’t secure the funds to finish building out its recycling hub in Rochester, New York, and it was acquired by the commodities trading and mining company Glencore last summer.

“We started really early, and in a way we started Redwood almost too early,” JB Straubel, Redwood’s founder and Tesla’s co-founder, told TechCrunch last summer. He was alluding to the fact that in 2017, when Redwood was founded, there just weren’t that many aging EVs on the road — nor are there yet today. So while an influx of used EV batteries is eventually expected, slower than anticipated EV adoption means there just may not be enough supply yet to sustain a company like Redwood on that business model alone.

In the meantime, Redwood has also worked to recycle and refine critical minerals from battery manufacturing scrap and used lithium-ion from consumer electronics. Partnerships with automakers such as Toyota, Volkswagen, and General Motors, as well as global battery manufacturer Panasonic, have helped bolster both its EV battery recycling business and new storage endeavor. The goal of building a domestic supply chain for battery materials such as lithium, nickel, cobalt, and copper also remains as bipartisan as ever, meaning Redwood certainly isn’t dropping the recycling and refining arm of its business, even as it shifts focus toward energy storage.

For instance, it’s also still working on the buildout of a recycling and battery component production facility in Charleston, South Carolina. While three years ago the company announced that this plant would eventually produce over 100 gigawatt-hours of cathode and anode battery components annually, operations on this front appear to be delayed. When Redwood announced that recycling and refining operations had begun in Charleston late last year, it made no mention of when battery component production would start up.

It’s possible that this could be taking a backburner to the company’s big plans to expand its storage business. While the initial Crusoe facility offers 63 megawatt-hours of battery energy storage, McConnell told me that Redwood is now working on projects “in the hundreds of megawatt-hours, looking to gigawatt-hour scale” that it hopes to announce soon.

The market potential is larger than any of us might realize. Over the next five or so years, McConnell said, “We expect that repurposed electric vehicle battery packs could make up 50% of the energy storage market.”

Fossil fuel companies colluded to stifle competition from clean energy, the state argues.

A new kind of climate lawsuit just dropped.

Last week the state of Michigan joined the parade of governments at all levels suing fossil fuel companies for climate change-related damages. But it’s testing a decidedly different strategy: Rather than allege that Big Oil deceived the public about the dangers of its products, Michigan is bringing an antitrust case, arguing that the industry worked as a cartel to stifle competition from non-fossil fuel resources.

Starting in the 1980s, the complaint says, ExxonMobil, Chevron, Shell, BP, and their trade association, the American Petroleum Institute, conspired “to delay the transition from fossil fuels to renewable energy” and “unlawfully colluded to reduce innovation” in Michigan’s transportation and energy markets. This, it alleges, is a key driver of Michigan’s (and the country’s) present-day struggles with energy affordability. If the companies had not suppressed renewable energy and electric vehicles, the argument goes, these technologies would have become competitive sooner and resulted in lower transportation and energy costs.

The framing may enable Michigan to sidestep some of the challenges other climate lawsuits have faced. Ten states have attempted to hold Big Oil accountable for climate impacts, mostly by arguing that the industry concealed the harms their products would cause. One suit filed by the City of New York has been dismissed, and many others have been delayed due to arguments over whether the proceedings belong in state or federal court, and haven’t yet gotten to the substance of the claims. Michigan’s tactic “maybe speeds up getting to the merits of the case,” Margaret Barry, a climate litigation fellow at Columbia University’s Sabin Center for Climate Change Law, told me, “because those jurisdictional issues aren’t going to be part of the court’s review.”

The fossil fuel industry’s primary defense in these suits has been that cities and states cannot fault oil companies for greenhouse gas emissions because regulating those emissions is the job of the federal government, per the Clean Air Act. Making the case about competition may “avoid arguments about whether this lawsuit is really about regulation,” Rachel Rothschild, an assistant professor of law at the University of Michigan, told me.

The biggest hurdle Michigan will face is proving the existence of a coordinated plot. Geoffrey Kozen, a partner at the law firm Robins Kaplan who works on antitrust cases, told me that companies in these kinds of suits tend to argue that they were simply reacting independently to the same market pressures and responding as any rational market actor would.

There are two main ways for a plaintiff to overcome that kind of argument, Kozen explained. In rare cases, there is a smoking gun — a memo that all of the parties signed saying they were going to act together, for example. More often, attorneys attempt to demonstrate a combination of “parallel conduct,” i.e., showing that all of the parties did the same thing, and “plus factors,” or layers of evidence that make it more likely that there was some kind of underlying agreement.

According to Michigan’s lawsuit, the collusion story in this case goes like this. In 1979, the American Petroleum Institute started a group called the CO2 and Climate Task Force. By that time, Exxon had come to understand that fossil fuel consumption was warming the planet and would cause devastation costing trillions of dollars. The company’s scientists had concluded that cleaner alternatives to fossil fuels would have to make up an increasing amount of the world’s energy if such effects were to be avoided.

“A self-interested and law-abiding rational firm would have used this insight to innovate and compete in the energy market by offering superior and cheaper energy products to consumers,” the complaint says. Michigan alleges that instead, Exxon shared its findings with the other companies in the task force and conspired with them to suppress clean alternatives to fossil fuels. They worked together to “synchronize assessments of climate risks, monitor each other’s scientific and industry outlooks, align their responses to competitive threats, and coordinate their efforts to suppress technologies likely to displace gasoline or other fossil fuels through collusion rather than competition,” according to the complaint.

Michigan’s lawyers point to evidence showing that the named companies shut down internal research programs, withheld products from the market, and used their control of patents to stifle progress away from fossil fuels. The companies were all early leaders in developing clean technologies — with innovations in rechargeable batteries, hybrid cars, and solar panels — but began to sabotage or abandon those efforts after the formation of the task force, the lawsuit alleges.

The case will likely turn on whether the judge finds it credible that these actions would have been against the companies’ self-interest had they not known their peers would be doing the same thing, Kozen told me.

“The actions differ between defendants. They are over a wide range of time periods. And so the question is, is that pursuant to an actual agreement? Or is it pursuant to a bunch of oil executives who are all thinking in similar ways?” he said. “I think that’s going to be the number one point where success or failure is probably going to tip.”

Another challenge for Michigan will be to prove what the world would have looked like had this collusion not taken place. In the parlance of antitrust, this is known as the “but-for world.” Without the Big Oil conspiracy, the lawsuit says, electric vehicles would be “a common sight in every neighborhood,” there would be ubiquitous “reliable and fast chargers,” and renewable energy would be “supplied at scale.” It argues that economic models show that Michigan’s energy prices would also have been significantly lower. While such arguments are common in antitrust cases, it’s a lot more difficult to quantify the effects of stifled innovation than something more straightforward like price fixing.

The companies, of course, reject Michigan’s narrative. A spokeswoman for Exxon told the New York Times it was “yet another legally incoherent effort to regulate by lawsuit.”

If the state can gather enough plausible evidence of harm, however, it may be able to get past the companies’ inevitable motion to dismiss the case and on to discovery. While the case is built on heaps of internal emails and leaked memos that have been made public over the years through congressional investigations, who knows how much of the story has yet to be revealed.

“It’s, in my experience, almost impossible, if someone is actually a member of a cartel, to hide all the evidence,” said Kozen. “Whatever it is, it always comes out.”

Current conditions: Temperatures as low as 30 degrees Fahrenheit below average are expected to persist for at least another week throughout the Northeast, including in New York City • Midsummer heat is driving temperatures up near 100 degrees in Paraguay • Antarctica is facing intense katabatic winds that pull cold air from high altitudes to lower ones.

The United States has, once again, exited the Paris Agreement, the first global carbon-cutting pact to include the world’s two top emitters. President Donald Trump initiated the withdrawal on his first day back in office last year — unlike the last time Trump quit the Paris accords, after a prolonged will-he-won’t-he game in 2017. That process took three years to complete, allowing newly installed President Joe Biden to rejoin in 2021 after just a brief lapse. This time, the process took only a year to wrap up, meaning the U.S. will remain outside the pact for years at least. “Trump is making unilateral decisions to remove the United States from any meaningful global climate action,” Katie Harris, the vice president of federal affairs at the union-affiliated BlueGreen Alliance, said in a statement. “His personal vendetta against clean energy and climate action will hurt workers and our environment.” Now, as Heatmap’s Katie Brigham wrote last year, at “all Paris-related meetings (which comprise much of the conference), the U.S. would have to attend as an ‘observer’ with no decision-making power, the same category as lobbyists.”

America has not yet completed its withdrawal from the United Nations Framework Convention on Climate Change, the overarching group through which the Paris Agreement was negotiated, which Trump initiated this month. That won’t be final until next year. That Trump is even planning to quit the body shows how much more aggressive the administration’s approach to climate policy is this time around. Trump remained within the UNFCCC during his first term, preferring to stay engaged in negotiations even after quitting the Paris Agreement.

Just weeks after a federal judge struck down the Trump administration’s stop work order on the Revolution Wind project off Rhode Island’s shores, another federal judge has overturned the order halting construction on the Vineyard Wind project off Massachusetts. That, as Heatmap’s Emily Pontecorvo wrote last night, “makes four offshore wind farms that have now won preliminary injunctions against Trump’s freeze on the industry.” Besides Revolution Wind, Dominion Energy’s Coastal Virginia offshore wind project and Equinor’s Empire Wind plant off Long Island have each prevailed in their challenges to the administration’s blanket order to abandon construction on dubious national security grounds.

Meanwhile, the White House is potentially starving another major infrastructure project of funding. The Gateway rail project to build a new tunnel under the Hudson River between New Jersey and New York City could run out of money and halt construction by the end of next week, the project manager warned Tuesday. Washington had promised billions to get the project done, but the money stopped flowing in October during the government shutdown. Officials at the Department of Transportation said the funding would remain suspended until, as The New York Times reported, the project’s contracts could be reviewed for compliance with new rules about businesses owned by women and minorities.

Sign up to receive Heatmap AM in your inbox every morning:

A new transmission line connecting New England’s power-starved and gas-addicted grid to Quebec’s carbon-free hydroelectric system just came online this month. But electricity abruptly stopped flowing onto the New England Clean Energy Connect as the Canadian province’s state-owned utility, Hydro-Quebec, withheld power to meet skyrocketing demand at home amid the Arctic chill. Power plant owners in New England and New York, where Hydro-Quebec is building another line down the Hudson River to connect to New York City, complained that deals with the utility focused on maintaining supplies during the summer, when air conditioning traditionally surges power to peak demand. Hydro-Quebec restored power to the line on Monday.

The storm represented a force majeure event. If it hadn’t, the utility would have needed to pay penalties. But the incident is sure to fuel more criticism from power plant owners, most of which are fossil fueled, who oppose increased competition from the Quebecois. “I hate to say it, but a lot of the issues and concerns that we have been talking about for years have played out this weekend,” Dan Dolan — who leads the New England Power Generators Association, a trade group representing power plant owners — told E&E News. “This is a very expensive contract for a product that predominantly comes in non-stressed periods in the winter,” he said.

Europe has signed what the European Commission president Urusula von der Leyen called “the mother of all deals” with India, “a free trade zone of 2 billion people.” As part of the deal, the world’s second-largest market and the most populous nation plan to ramp up exports of steel, plastics, chemicals, and pharmaceuticals. But don’t expect Brussels to give New Delhi a break on its growing share of the global emissions. The EU’s carbon border adjustment mechanism — the first major tariff in the world based on the carbon intensity of imports — just took effect this month, and will remain intact for Indian goods, Reuters reported.

The Department of the Interior has ordered staff at the National Park Service to remove or edit signs and other informational materials in at least 17 parks out West to scrub mentions of climate change or hardship inflicted by settlers on Native Americans. The effort comes as part of what The Washington Post called a renewed push to implement Trump’s executive order on “restoring truth and sanity to American history.” Park staff have interpreted those orders, the newspaper reported, to mean eliminating any reference to historic racism, sexism, LGBTQ rights, and climate change. Just last week, officials removed an exhibit at Independence National Historical Park on George Washington’s ownership of slaves.

Tesla is going trucking. The electric automaker inked a deal Tuesday with Pilot Travel Centers, the nation’s largest operator of highway pit stops, to install Tesla’s Semi Chargers for heavy-duty electric vehicle charging. The stations are set to be built at select Pilot locations along Interstate 5, Interstate 10, and several other major corridors where heavy-duty charging is highest. The first sites are scheduled to open this summer.