You’re out of free articles.

Log in

To continue reading, log in to your account.

Create a Free Account

To unlock more free articles, please create a free account.

Sign In or Create an Account.

By continuing, you agree to the Terms of Service and acknowledge our Privacy Policy

Welcome to Heatmap

Thank you for registering with Heatmap. Climate change is one of the greatest challenges of our lives, a force reshaping our economy, our politics, and our culture. We hope to be your trusted, friendly, and insightful guide to that transformation. Please enjoy your free articles. You can check your profile here .

subscribe to get Unlimited access

Offer for a Heatmap News Unlimited Access subscription; please note that your subscription will renew automatically unless you cancel prior to renewal. Cancellation takes effect at the end of your current billing period. We will let you know in advance of any price changes. Taxes may apply. Offer terms are subject to change.

Subscribe to get unlimited Access

Hey, you are out of free articles but you are only a few clicks away from full access. Subscribe below and take advantage of our introductory offer.

subscribe to get Unlimited access

Offer for a Heatmap News Unlimited Access subscription; please note that your subscription will renew automatically unless you cancel prior to renewal. Cancellation takes effect at the end of your current billing period. We will let you know in advance of any price changes. Taxes may apply. Offer terms are subject to change.

Create Your Account

Please Enter Your Password

Forgot your password?

Please enter the email address you use for your account so we can send you a link to reset your password:

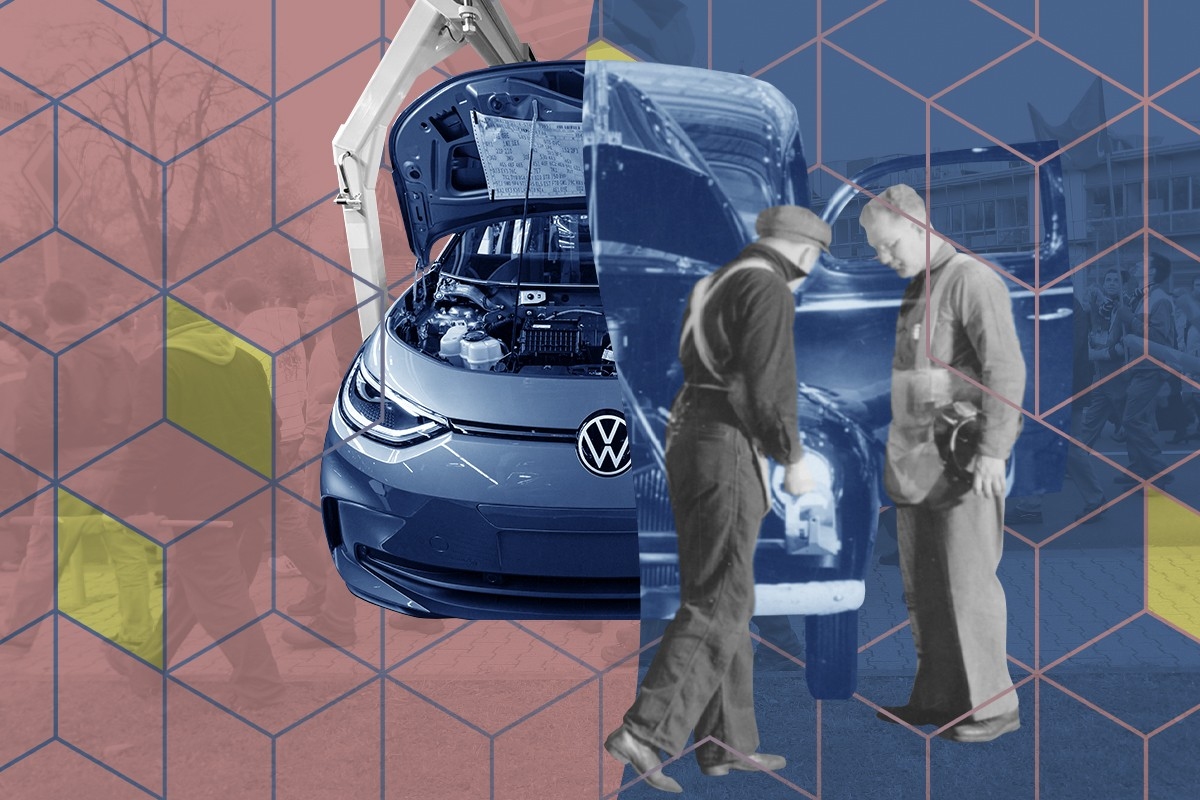

At the stroke of midnight, employees at three plants owned by General Motors, Ford, and Jeep walked off the job. None of those plants make electric vehicles, unless you count the plug-in hybrid Jeep Wrangler. But make no mistake — the strike by the United Auto Workers union, its most aggressive labor actions since the 1930s, plays directly into a larger fight over the battery-driven future of the car industry. And that fight has already gone global; you may have just not noticed it yet.

There are a lot of complicated, interwoven issues driving the UAW’s strike, which will start with those three plants but may include more if negotiations deteriorate. First and foremost is pay and benefits at America’s existing UAW plants. Like everyone who’s not fortunate enough to be in the top tax bracket, the UAW’s workers have been stung by inflation and higher costs of living. What was once a well-defined path to middle-class life has been hammered in the last decade as carmaking jobs got sent to Mexico and China. This, after those auto workers made tremendous concessions to keep their employers afloat during the Great Recession and subsequent auto industry bailouts, only to see some of their top leaders go to prison for taking bribes while also failing to increase their ranks at companies like Nissan and Tesla. They’re pissed, and they have every right to be pissed.

But that’s only part of the challenge here. The other issue that looms over this showdown has to do with electric vehicles. Take the battery plants springing up all over America, spurred in large part by incentives from the Biden Administration’s Inflation Reduction Act. Nowhere does this pro-EV legislation say that the green jobs coming soon have to be union jobs, even if they’re building batteries for tomorrow’s EVs. Meanwhile, EVs generally require far less labor and parts to build than their gasoline-powered counterparts; they’re essentially batteries, bodies, software and an assortment of other components. Engines and transmissions are complicated things, but they’re simply not necessary for what’s coming. It’s often believed that the transition to EVs will mean fewer auto industry jobs, period; that’s actually very hard to gauge, but it’s no stretch to think this transition won’t be easy, seamless, or provide a comparable job for every single worker — including those at the many related companies that supply various parts and components.

But you can probably see where this is going. If you have a good-paying union job making trucks or transmissions for General Motors, what happens to you when they need fewer workers someday to assemble an electric truck — or when complex nine-speed automatic transmissions designed to work with gas engines aren’t needed at all? And if you’re a worker at the GM’s Ultium battery plant in Ohio, why are you making almost half what your counterparts are to build the future of the American auto industry? In other words: Will the electric future of the car business include good jobs for those who build them, or not?

Those who follow the auto industry, or work in it, have been seeing this play out elsewhere for some time now, especially in countries with far stronger labor unions than America generally has. In Europe, Volkswagen has been cutting thousands of jobs for years now as it attempts to shore up money to pay for a costly electric transition (something it’s clearly struggling with.) BMW’s CEO made waves last year for promising not to do the same, but whether he can actually make good on it or not remains to be seen. In Japan, former Toyota president (and current chairman) Akio Toyoda has warned of millions of job losses in that country alone if the industry goes all-electric. The same job-loss fears have led to labor actions in South Korea, too, home of Hyundai Motor Group, one of the most EV-ambitious car companies in the world. Who knows; if these unions team up, who’s to say we won’t see coordinated strikes as part of a global action?

Essentially, versions of this fight are playing out everywhere cars are made, and it’s hard to see an endgame to that no matter where you go. The story is the same everywhere: whatever the future of the auto industry is, it may just not need as many jobs as it has now, and even if it does, a ton of people will get lost in the shuffle.

Adding to all of this is a rising China, which is turning out some seriously impressive EVs that have Europe’s automakers rightfully spooked. (Those cars are kept out of our market by steep tariffs, for now anyway.) On top of being actually good, those cars are much cheaper than the competition. Why? Besides China getting great at building them at scale, there are deeply questionable labor practices, to put it politely, across all of that country’s battery and EV supply chain.

And then there’s the staggering cost involved with these companies’ transition to becoming EV companies, something not all of them will survive. Here in America, if you ask the Big Three automakers, they simply cannot afford to grant the UAW’s pay raise demands. Not as they invest trillions of dollars over the next few decades to transition to an industry driven by batteries and software instead of engines and hardware features. The automakers are dealing with a workforce that feels like it’s been left behind,, the costs involved with pivoting their businesses, and the ever-insatiable demands of shareholders.

It’s a tough spot to be in, but then again, each of the Big Three is led by an executive making at least $20 million per year, so maybe they can figure something out, particularly when they’re raking in record profits.

It’s possible that the battery plants will be key to saving auto industry jobs. Engineering researchers at Carnegie Mellon have found that while fewer auto parts are needed in EVs, battery manufacturing is so complex that the overall labor needs might potentially even out. And it’s true that battery factories are certainly popping up everywhere EVs are sold, not just in America.

But here, there’s an added complication: Most battery factories being built are ventures with companies like LG and SK On, which do not have agreements with the UAW. In other words, there’s no guarantee those will automatically be good-paying union jobs. Granted, the UAW has already scored a small victory on that front. Workers at GM’s LG joint venture battery plant in Ohio plant voted overwhelmingly to join the UAW last December, and as union negotiations went on this year, GM acquiesced and granted them a 25% raise and back pay — though they’d still be paid less than other UAW members. Maybe that will change as negotiations are finalized, but it may also not get fully resolved in this contract process.

Finally, there’s the question of what this strike means for the rest of the industry. It’s entirely possible that if the UAW gets an extremely favorable contract, it will aim its guns at Tesla next, or the Asian and European U.S.-based plants that have eluded unionization for so long. Surely, Honda and Volkswagen’s American workers have concerns about their future too, and Tesla’s workers make $20 an hour less in wages and benefits than their UAW counterparts.

If the UAW can score some major wins here, there’s nothing to say this can’t be the start of something bigger.

Log in

To continue reading, log in to your account.

Create a Free Account

To unlock more free articles, please create a free account.

It’s an idea with bipartisan appeal, but AOC’s former policy adviser argues that the scale of the data center problem is too big for that.

Last night, between the trumpeting of fossil fuels and the lengthy honors awarded to both veterans and hockey players, President Trump devoted a portion of his State of the Union address to announcing a “ratepayer protection pledge,” under which big tech companies pay for their own power plants for data centers — a show of how central energy prices are becoming to today’s affordability debate.

Electricity in the United States is rapidly becoming expensive and unreliable. Vast swaths of the United States are at elevated risk of outages. January’s winter storms wiped out power for millions of Americans from Louisiana to Brooklyn. In 2025, utilities requested a record $31 billion in rate increases from captive customers. Gas and electricity prices are the two highest drivers of inflation.

The main driver of these new stressors on the grid: the expected $6.7 trillion to be deployed in data centers by 2030.

Policymakers at all levels of governments are coalescing on a strategy for dealing with rising data center demand that mirrors Trump’s ratepayer protection pledge: “bring your own generation,” or BYOG. Bipartisan bills introduced in Washington by Senators Chris Van Hollen, and Josh Hawley and Richard Blumenthal; and by Representatives Rob Menendez and Greg Casar, among others, would require hyperscalers like Meta, OpenAI, and Microsoft to pay for their own power plants and grid upgrades in order to plug in. Michigan, Oregon, Florida, Washington, Georgia, Illinois, and Delaware are all at various stages of enacting BYOG legislation for data centers.

BYOG would create something like a regulatory sandbox for data centers, insulating utilities and ratepayers from the risks of data center demand. But while efforts at consumer protection are important, these policies do not grapple with the scale of data center deployment.

A sandbox won’t withstand a tidal wave. Over the next five years, the equivalent of 17 to 32 New York Cities’ worth of electricity demand is expected to be added to the grid, more than half of which will come from data centers. This incredibly wide estimate means that generators risk overbuilding.

Amidst all this uncertainty, BYOG does not address who pays for new capacity in the event the AI bubble bursts and energy infrastructure is left stranded. Neither does BYOG address the drastically mismatched lifetimes of the chips powering AI (one to three years) and power plants (25 to 30 years). The Federal Energy Regulatory Commission expects 22 New York Cities’ worth of generation to be added to the grid by 2028. Who pays for all of this generation in a decade if even 5% of projected data center demand disappears?

AI is a promising technology, but that does not prevent it from being overvalued. Policymakers must consider the risks when data centers eventually disconnect from the grid, not just when they interconnect. This means ensuring that ratepayers and taxpayers are not left footing the bill for stranded energy infrastructure if data centers disconnect prematurely.

Rather than cordoning off data centers from the rest of the electricity market, policymakers should take a stronger hand in planning these deployments for social and economic benefit. Colocating datacenters with energy-intensive industries and requiring long-term commitments from hyperscalers are more efficient solutions that would also make new data centers more politically palatable.

Public sentiment has turned overwhelmingly against data center development. These vast facilities create relatively few jobs beyond their construction, but colocated with the manufacture of energy-intensive products like aluminum, steel, or fertilizer, suddenly they’re supporting employment. Colocation will also help diversify economic growth. Data center investment was responsible for a whopping 92% of GDP growth in the first half of 2025, creating a potentially dangerous dependency on continued expansion.

There are also simple legal guardrails that can provide a first line of defense against stranded costs. One is requiring long-term power purchase agreements between hyperscalers and generators. Thirteen bipartisan governors and the Trump administration recently urged the country’s largest grid operator, PJM Interconnection, to require 15-year generation contracts for hyperscalers. Notably, Van Hollen’s bill would only require states to “consider” the extension of “minimum utility contract lengths,” while the Hawley/Blumenthal and Menendez/Casar bills make no mention of contract length or stranded costs.

Hyperscalers can also curtail usage during peak demand, a policy that has seen bipartisan support in Texas. A now-famous study from Duke University last year found that if data centers were to curtail 1% of their usage during peak hours, they could avoid installing 126 gigawatts of new generation — that’s 21 New York Cities’ worth. Lawmakers have since taken to the idea. Several states are considering mandating so-called “demand response” programs, and Representatives Alexandria Ocasio-Cortez and Kathy Castor inserted a federal study on demand response into the appropriations bill Trump signed in January.

Regardless of how it’s done, ratepayers should not pay full freight for the tidal wave of infrastructure coming online, and most utility balance sheets should not be exposed to that risk. BYOG’s flaws have more to do with what it leaves out — namely that the planning of significant parts of our economy and electric system is left to tech companies, and little thought is given to the long-term ramifications of overbuilding. Rather than deal reactively with the nasty politics of a bailout, policymakers should make muscular interventions now to reduce risks for ratepayers and taxpayers.

Energy markets are not free markets. For the past century they have been heavily regulated at the state, regional, and federal level. Any discomfort with planning (or “statutory tools”) must be set aside if policymakers are going to efficiently manage the growth of data centers.

On Cybertruck deaths, Texas wind waste, and American aluminum

Current conditions: Yet more snow is dusting New York City with at least an inch fallen already, though that’s set to turn into rain later in the morning • Authorities in Saudi Arabia issued a red alert over a major sandstorm blasting broad swaths of the desert nation • Heavy snow blanketed Romania, halting transportation and taking down power lines.

In his State of the Union address Tuesday night, President Donald Trump unveiled what he called the new “ratepayer protection pledge.” Under the effort, the White House will tell “major tech companies that they have the obligation to provide for their own power needs.” By mandating the bring-your-own-generation approach, the Trump administration is endorsing a push that’s been ongoing for months. The North American Electric Reliability Corporation, the U.S. grid watchdog, called for data centers to build their own generators. An industry-backed proposal in the nation’s largest power grid would do something similar. “This is a unique strategy,” Trump said. “We have an old grid that could never handle the [amount] of electricity that’s needed.” With tech companies constructing new power plants, Trump said, towns should welcome data center projects that could end up lowering electricity rates by inviting more power onto the local grid.

The political blowback to data centers is gaining strength. It is, as my colleague Jael Holzman wrote recently, “swallowing American politics.” On the right, Senator Josh Hawley, the populist Republican from Missouri, introduced legislation this month to restrict data center construction. On the left, Senator Bernie Sanders, the democratic socialist from Vermont, reiterated his proposal this week to halt all data center projects. In the center, Pennsylvania Governor Josh Shapiro, a Democrat with unusually strong support among his state’s GOP voters, recently outlined plans for a more “selective” approach to data centers, as I reported in this newsletter.

Trump isn’t the only Republican pushing back against the data center blowback. On Tuesday, Mississippi Governor Tate Reeves delivered an impassioned defense of his state’s data center buildout. “I understand individuals who would rather not have any industrial project in their backyard. We all choose where to live, whether it’s urban, suburban, agrarian, or industrial. I do not understand the impulse to prevent our country from advancing technologically — except as civilizational suicide,” Reeves wrote in a post on X. “I don’t want to go gently. I love this country, and want her to rise. That’s why Mississippi has become the home of the world’s most impressive supercomputers. We are committed to America and American power. We know that being the hub of the world’s most awesome technology will inevitably bring prosperity and authority to our state. There is nobody better than Mississippians to wield it.”

Replying to Sanders’ proposal, Reeves said he’s “tempted to sit back and let other states fritter away the generational chance to build. To laugh at their short-sightedness. But the best path for all of us would be to see America dominate.”

Sign up to receive Heatmap AM in your inbox every morning:

The subcompact Ford Pinto gained infamy in the 1970s for its tendency to explode when the gas tank ruptured in a crash. The Ford Motor Company sold just under 3.2 million Pintos. By the official death toll, 27 people died as a result of fires from the vehicles exploding. Tesla has sold more than 34,000 Cybertrucks; already, five people have died in fire fatalities.

That, according to a calculation by the automotive blog Fuel Arc, means the Tesla Cybertruck has 14.52 deaths per 100,000 units, compared to the Ford Pinto’s 0.85 deaths. “The Cybertruck is far more dangerous (by volume) than the historic poster child for corporate greed and grossly antagonistic design,” Fuel Arc’s Kay Leadfoot wrote. “I look forward to the Cybertruck being governmentally crash-tested by the NHTSA, which it has not been thus far. Until then, I can’t recommend sitting in one.” That is, however, based on the lower death toll figure for the Pinto. Back in 1977, Mother Jones published a blockbuster cover story under the headline “Pinto Madness” claiming that the number of deaths could be as high as 900.

Texas accused the recycling company Global Fiberglass Solutions of illegally dumping thousands of wind turbine blades near the central town of Sweetgrass. The company allegedly hired several subcontractors to break down, transport and recycle the blades, but failed to properly dispose of the waste and instead created what Windpower Monthly called a “stockpile” of more than 3,000 blades across two sites in the town. Attorney General Ken Paxton, a Republican candidate for U.S. Senate, seized on a Trumpian critique of the energy source, saying the dumps damage “beautiful Texas land and threaten surrounding communities.”

Off the Atlantic Coast, meanwhile, Orsted is at a transitional moment for two of its offshore wind projects. The Danish developer just brought the vessel Wind Scylla to port after completing the installation of turbines at its Revolution Wind project in New England. The boat is headed to New York next to start installing the first wind turbine at Sunrise Wind, according to OffshoreWIND.biz.

Last month, I told you that Century Aluminum inked a deal with Emirates Global Aluminum to build the first smelter in the U.S. in half a century in Oklahoma. On Tuesday, the U.S. Aluminum Company, a local firm in the state, joined the project, signing an agreement to “explore the development of an aluminum fabrication plant near the new smelter.” If completed, the project — already dubbed Oklahoma Primary Aluminum — would roughly double U.S. primary production of the metal.

The Biden administration had placed what Heatmap’s Matthew Zeitlin called “a big bet on aluminum” back in 2024. By spring of last year, our colleague Katie Brigham was chronicling the confusion over how Trump’s tariffs on aluminum would work. With the recent Supreme Court ruling upending Trump’s trade policies, that one may remain a headscratcher for a little while longer.

Another day, another landmark energy investment from Google. This time, the tech giant has made a deal with the long-duration energy storage startup Form Energy to deploy what Katie wrote “would be the largest battery in the world by energy capacity: an iron-air system capable of delivering 300 megawatts of power at once while storage 30 gigawatt-hours of energy, enabling continuous discharge for 100 hours straight.” The project will power a data center in Minnesota. “For all of 2025, I believe the installed capacity [added to the grid] in the entire U.S. was 57 gigawatt-hours. And in one project, we’re going to install 30 gigawatt-hours,” Form CEO Mateo Jaramillo told Katie. “What it highlights is, once you get to the 100-hour duration, you can really stop thinking about energy to some extent. “

Rob checks in with Near Horizon Group’s Peter Freed about the AI boom’s power needs.

Just a handful of tech companies plan to spend nearly $700 billion combined this year investing in artificial intelligence — and much of that money will go to data centers and the energy used to keep them on. How is this boom transforming the American energy system, and what does it mean for clean energy?

On this episode of Shift Key, Rob is joined by Peter Freed, a founding partner at the Near Horizon Group and the former director of energy strategy at Meta from 2014 to 2024. They discuss why data center developers opt for certain energy sources over others, why AI is driving an unprecedented off-grid natural gas boom, and why batteries now pair especially well with gas. Yikes!

This conversation was originally recorded for a webinar hosted by Heatmap Pro. Shift Key is hosted by Robinson Meyer, the founding executive editor of Heatmap News.

Subscribe to “Shift Key” and find this episode on Apple Podcasts, Spotify, Amazon, or wherever you get your podcasts.

You can also add the show’s RSS feed to your podcast app to follow us directly.

Here is an excerpt from their conversation:

Robinson Meyer: We know there’s this giant capex surge coming from the hyperscalers. I mean, it’s reached the point now where tech companies’ stocks suffer when they announce investment because they seem to be in an arms race of spending on data centers. We were just talking about the behind the meter gas boom. There’s a lot of renewable energy developers in this audience, or battery developers. How should they be thinking about this moment and what do they need to be doing to make their projects or to work with data center developers in the most attractive way?

Peter Freed: I’ll bring us back a couple of minutes to when I said, look, if you’re a data center developer and you’re building gas plus storage and you’re thinking of that as a pretty complicated thing, someone is really going to have to work out on explaining why the introduction of a variable renewable resource into that configuration is worthwhile.

And obviously there are people that believe that that’s true. Intersect believed that that was true and it worked out really, really well for them. There are ways to tell that story. And I think that the renewable energy development community probably still has some work to do to help explain that. So that’s sort of thing number one — like, the closer you get to the operations of the data center facility, the more work you’re going to have to do to explain why you believe that the integration of renewables into that makes sense.

Now, you can remove yourself somewhat from the actual operations of the facility. And this is where we get into bring your own capacity conversations. And you know, there’s been some really interesting stuff sort of talking about, okay, maybe there is a utility which has sufficient wires capacity as — and like, there’s enough room on the transmission lines to plug a data center in and turn the lights on, but they don’t have enough market capacity. Like, they don’t have enough of the financial products required by the RTO that they operate in to serve that facility. And so that can become an interesting opportunity for renewables in particular, storage in particular, trying to figure out how to put together these bring your own capacity products to serve data centers.

And I’ll say, you know, when I first heard about these bring your own capacity opportunities, I thought that they were pretty niche. I was like, okay, well, you know, a utility has sufficient wires capacity to serve a giant data center, but they don’t have capacity in the market. Like, that feels like something that’s not going to happen that often. But apparently, I mean, I was incorrect.

You can find a full transcript of the episode here.

Mentioned:

Breaking Down the Doomsday AI Memo That Spooked Markets

Inside Form Energy’s Big Google Data Center Deal

The New York Times on AI’s polling problems

Previously on Shift Key: What’s Really Holding Back New Data Centers

This episode of Shift Key is sponsored by …

Heatmap Pro brings all of our research, reporting, and insights down to the local level. The software platform tracks all local opposition to clean energy and data centers, forecasts community sentiment, and guides data-driven engagement campaigns. today to see the premier intelligence platform for project permitting and community engagement. Book a demo today to see the premier intelligence platform for project permitting and community engagement.

Music for Shift Key is by Adam Kromelow.