You’re out of free articles.

Log in

To continue reading, log in to your account.

Create a Free Account

To unlock more free articles, please create a free account.

Sign In or Create an Account.

By continuing, you agree to the Terms of Service and acknowledge our Privacy Policy

Welcome to Heatmap

Thank you for registering with Heatmap. Climate change is one of the greatest challenges of our lives, a force reshaping our economy, our politics, and our culture. We hope to be your trusted, friendly, and insightful guide to that transformation. Please enjoy your free articles. You can check your profile here .

subscribe to get Unlimited access

Offer for a Heatmap News Unlimited Access subscription; please note that your subscription will renew automatically unless you cancel prior to renewal. Cancellation takes effect at the end of your current billing period. We will let you know in advance of any price changes. Taxes may apply. Offer terms are subject to change.

Subscribe to get unlimited Access

Hey, you are out of free articles but you are only a few clicks away from full access. Subscribe below and take advantage of our introductory offer.

subscribe to get Unlimited access

Offer for a Heatmap News Unlimited Access subscription; please note that your subscription will renew automatically unless you cancel prior to renewal. Cancellation takes effect at the end of your current billing period. We will let you know in advance of any price changes. Taxes may apply. Offer terms are subject to change.

Create Your Account

Please Enter Your Password

Forgot your password?

Please enter the email address you use for your account so we can send you a link to reset your password:

Research from the Institute for Energy Economics and Financial Analysis calls blue hydrogen’s carbon math into question.

The largest hydrogen producer in the world, Air Products, stands to earn up to $440 million per year in clean energy tax credits once it opens its massive, $7 billion complex in Louisiana in 2028. But a recent report argues that while the hydrogen produced there will be highly profitable for Air Products, it’s a “lose-lose proposition” for the environment — and for taxpayers.

The research adds to the long-running debate around the climate benefits of “blue hydrogen,” which is produced via the separation of hydrogen molecules from carbon molecules in natural gas, with systems that capture the resulting carbon emissions and store them underground. Advocates of the technology say it’s a critical bridge to a renewables-powered hydrogen economy, as it allows for cleaner hydrogen production now by relying on existing infrastructure. Critics, however, say that blue hydrogen’s emissions benefits are minimal if any, and that a focus on this technology diverts money from more meaningful climate solutions.

The blue hydrogen produced at Air Products’ Louisiana facility will be eligible for the lucrative 45Q carbon sequestration tax credit, which was expanded by the Inflation Reduction Act in 2022 and provides up to $85 per metric ton of carbon that’s permanently locked away.

The March report from the Institute for Energy Economics and Financial Analysis, however, argues that Air Products makes overly optimistic assumptions about both methane leakage rates and the effectiveness of carbon capture equipment, while underestimating the potency of methane in the short term. The company’s estimates are largely based on a Department of Energy life cycle analysis tool, which the report's authors also believe is flawed. The result, the authors write, is that the Louisiana plant would “cost billions of dollars in subsidies for essentially zero environmental benefit.”

With lawmakers in Congress considering which IRA tax credits to preserve and which ones to cut to make way for Trump’s spending priorities, now is a critical moment for climate-focused policymakers to have their priorities in order. It’s worth asking which provisions from Biden’s signature climate law are actually delivering a climate bang for their buck.

Air Products says that its Louisiana facility will sequester 5 million metric tons of CO2 annually over the 12 years that it’s eligible for the tax credit, which equates to $6.3 billion in total tax savings. To state the obvious, that’s a lot of taxpayer money for a project that a leading research group asserts will likely be a net negative for the environment.

“As you start expanding the envelope to take into account the full footprint and the full impact of this project and its product, there’s just not much of a benefit there, if any. It may be making things worse.” Anika Juhn, an energy data analyst at IEEFA and one of the report’s authors, told me. These findings are not specific just to Air Products’ upcoming facility — they’re “broadly applicable to other blue hydrogen projects,” Juhn said. (My colleague Emily Pontecorvo, for instance, wrote about a similar finding regarding methane leakage from the Permian Basin.) At least four of the DOE’s seven hydrogen hubs rely on natural gas with carbon capture and storage to some degree. Meanwhile, the Trump administration is looking to cut funding for the hubs that primarily produce hydrogen via renewable energy.

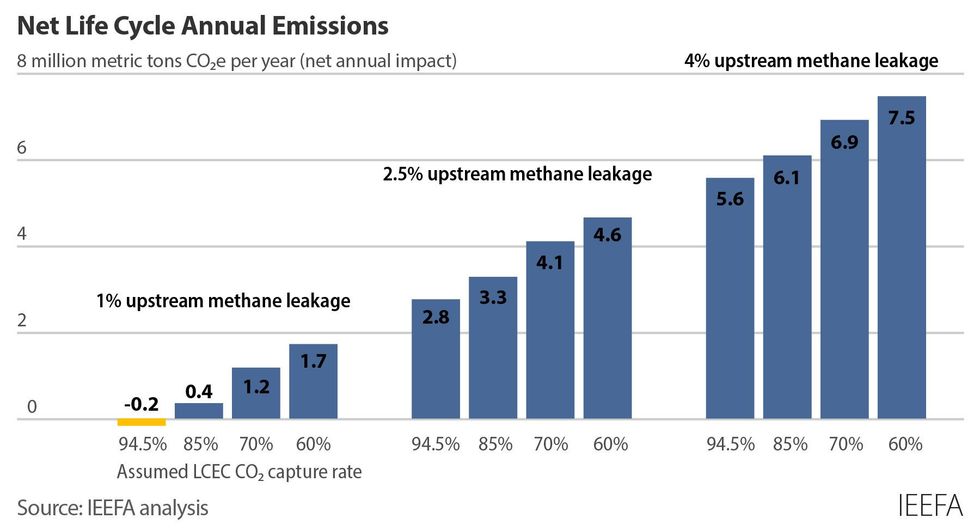

The DOE’s life cycle analysis tool uses an industrial methane leakage rate of 0.9% and a carbon capture rate of 94.5% for the specific method the Air Products facility will use, called autothermal reforming. (Or at least that’s what the IEEFA report said — I couldn’t find evidence of this carbon capture number in the government’s model itself.)

When Juhn and her co-author David Schlissel adjusted the analysis of Air Products’ Louisiana project using more typical industrial methane leakage rates of 1% to 4% and carbon capture rates ranging from 60% to 94.5%, they found that only under the most optimistic scenario would the project yield any carbon reductions at all. Even then, avoided emissions would only be about 200,000 metric tons per year of CO2 equivalent, whereas at the high end of the report’s “realistic scenario,” the project could result in an additional 7.5 million metric tons of CO2 equivalent annually.

To calculate the net life cycle emissions of a hydrogen project, the authors had to take the estimated benefits of hydrogen production into account, a task complicated by the fact that Air Products hasn’t announced any offtakers, making it impossible to know what dirtier (or cleaner) options customers might turn to if they didn’t have access to blue hydrogen. So instead, IEEFA relied on the White House’s general estimate that the 3 million metric tons of blue and green hydrogen (i.e. hydrogen released from water molecules using carbon-free electricity) produced by the hydrogen hubs would displace 25 million metric tons of CO2. But because the White House didn’t release its formula for determining avoided emissions, take their numbers with a grain of salt.

All of Air Products’ calculations thus come with the usual caveat, which is that they’re measured against an unknowable counterfactual — essentially a best guess at what would happen if plans for the Air Products facility went poof. Would the end users opt for hydrogen alternatives or would they rely on a standard natural gas-powered hydrogen facility with no carbon capture? Is it possible that a green hydrogen plant using renewables-powered electrolysis would be built instead?

All we know is that a portion of the hydrogen will be turned into ammonia and exported abroad, where Juhn told me it’s likely to be burned as fuel. Another portion will be injected into an existing 700-mile hydrogen pipeline on the Gulf Coast for use by existing customers in industries such as energy, transportation and chemicals.

While Air Products did not respond to my request for comment on the report, I was able to discuss the results with John Thompson, a director at the climate nonprofit Clean Air Task Force, which advocates for a wide array of climate-focused technologies, including hydrogen with carbon capture and storage. He took issue with the IEEFA study’s methodology, and told me that blue hydrogen projects have the potential to be a big win for the climate, so long as they’re replacing “gray” hydrogen projects — that is, those powered by natural gas with no carbon capture.

“When you do displace gray hydrogen, you get huge, huge benefits,” Thompson told me. Despite all the unknowns involved, he’s confident the Louisiana project will do just that, primarily due to the existing network of hydrogen pipelines at the site. “Those pipelines are there because they’re serving existing customers — refineries, ammonia plants, chemical manufacturing,” he said, meaning that “the likelihood that you’re displacing existing sources is pretty great.”

Thompson also took issue with the notion that a 95% capture rate is overly optimistic, telling me that there’s no technical barriers to achieving industrial capture rates in the 90s. “The 95% capture rate that they’re proposing to build towards is what is commercially guaranteed by many vendors,” Thompson said. “It hasn’t been widely used, not because it’s not commercially available, but because it’s costly, and there hasn’t been much demand for it until we got into climate considerations.”

To Thompson, the IEEFA report looked more like an “advocacy piece.” To IEEFA, the Louisiana project still appears to be a government subsidized money-making scheme. Notably, the Air Products facility probably will not qualify for the much debated 45V clean hydrogen production tax credit, the most generous subsidy of all in the IRA. That credit provides up to $3 per kilogram of clean hydrogen produced — a whopping $3,000 per metric ton — for projects with the lowest emissions intensity. It’s also tech-neutral, meaning that so long as blue hydrogen projects have life cycle emissions under 4 kilograms of carbon dioxide equivalent per kilogram of hydrogen produced, they will be eligible for at least a $0.60 credit per kilogram of clean hydrogen.

Air Products said last May that it would not even attempt to claim this credit for the Louisiana facility, even as the company asserts that the complex will produce “near-zero carbon emissions.” A 2023 DOE report indicated few blue hydrogen projects will be eligible, period, given “the added [natural gas] and electricity needed to run the [carbon capture and storage] facility.”

So at least by the DOE’s own standards, the hydrogen produced by Air Products will not be “clean.” That’s not a precondition for the carbon sequestration tax credit, though, which doesn’t demand life cycle analysis, just proof that you’re putting a certain amount of CO2 in the ground. Juhn thinks that’s a big mistake. These analyses are “the only way that you can know whether or not investing in CCS projects makes sense, either in a climate sense or in a financial sense,” she told me.

But as fossil fuel interests including Occidental and ExxonMobil have advocated for preserving and even increasing the 45Q tax credit, Juhn doesn’t expect to see any changes to the rule that would mandate more stringent requirements.

“I do hear the fossil fuel industry saying, Oh, we need blue hydrogen first because we can get things moving. We can get this online and we can start creating this product to stimulate demand,” she told me, citing a common argument that blue hydrogen is a necessary stepping stone to creating a robust, economical green hydrogen economy. “But the problem is that these facilities, they’re not going to go away when green hydrogen projects come online, and these projects are being built with a 25-, 30-year lifespan.”

At the very least, what everyone can agree on is the need to address upstream methane leakage. “It’s not enough to do carbon capture, I can’t emphasize that enough,” Thompson told me, pointing out that methane emissions are “not a law of thermodynamics” but rather “a variable that we can control if we choose to.” Unfortunately, it looks like the Trump administration won’t be choosing to, as the president recently signed legislation scrapping a Biden-era rule that imposed fees on oil and gas producers who emit excess methane.

Log in

To continue reading, log in to your account.

Create a Free Account

To unlock more free articles, please create a free account.

Batteries can only get so small so fast. But there’s more than one way to get weight out of an electric car.

Batteries are the bugaboo. We know that. Electric cars are, at some level, just giant batteries on wheels, and building those big units cheaply enough is the key to making EVs truly cost-competitive with fossil fuel-burning trucks and cars and SUVs.

But that isn’t the end of the story. As automakers struggle to lower the cost to build their vehicles amid a turbulent time for EVs in America, they’re looking for any way to shave off a little expense. The target of late? Plain old wires.

Last month, when General Motors had to brace its investors for billions in losses related to curtailing its EV efforts and shifting factories back to combustion, it outlined cost-saving measures meant to get things moving in the right direction. While much of the focus was on using battery chemistries like lithium ion phosphate, otherwise known as LFP, that are cheaper to build, CEO Mary Barra noted that the engineers on every one of the company’s EVs were working “to take out costs beyond the battery,” of which cutting wiring will be a part.

They are not alone in this obsession. Coming into a do-or-die year with the arrival of the R2 SUV, Rivian said it had figured out how to cut two miles of wires out of the design, a coup that also cuts 44 pounds from the vehicle’s weight (this is still a 5,000-pound EV, but every bit counts). Ford has become obsessed with figuring out smarter and cheaper ways for its money-hemorrhaging EV division to build cars; the company admitted, after tearing down a Tesla Model 3 to look inside, that its Mustang Mach-E EV had a mile of extra and possibly unnecessary wiring compared to its rival.

A bunch of wires sounds like an awfully mundane concern for cars so sophisticated. But while every foot adds cost and weight, the obsession with stripping out wiring is about something deeper — the broad move to redefine how cars are designed and built.

It so happens that the age of the electric vehicle is also the age of the software-defined car. Although automobiles were born as purely mechanical devices, code has been creeping in for decades, and software is needed to manage the computerized fuel injection systems and on-board diagnostic systems that explain why your Check Engine light is illuminated. Tesla took this idea to extremes when it routed the driver’s entire user interface through a giant central touchscreen. This was the car built like a phone, enabling software updates and new features to be rolled out years after someone bought the car.

As Tesla ruled the EV industry in the 2010s, the smartphone-on-wheels philosophy spread. But it requires a lot of computing infrastructure to run a car on software, which adds complexity and weight. That’s why carmakers have spent so much time in the past couple of years talking about wires. Their challenge (among many) is to simplify an EV’s production without sacrificing any of its capability.

Consider what Rivian is attempting to do with the R2. As InsideEVs explains, electric cars have exploded in their need for electronic control units, the embedded computing brains that control various systems. Some models now need more than 100 to manage all the software-defined components. Rivian managed to sink the number to just seven, and thus shave even more cost off the R2, through a “zonal” scheme where the ECUs control all the systems located in their particular region of the vehicle.

Compared to an older, centralized system that connects all the components via long wires, the savings are remarkable. As Rivian chief executive RJ Scaringe posted on X: “The R2 harness improves massively over the R1 Gen 2 harness. Building on the backbone of our network architecture and zonal ECUs, we focused on ease of install in the plant and overall simplification through integrated design — less wires, less clips and far fewer splices!”

Legacy automakers, meanwhile, are racing to catch up. Even those that have built decent-selling quality EVs to date have not come close to matching the software sophistication of Tesla and Rivian. But they have begun to see the light — not just about fancy iPads in the cockpit, but also about how the software-defined vehicle can help them to run their factories in a simpler and cheaper way.

How those companies approach the software-defined car will define them in the years to come. By 2028, GM hopes to have finished its next-gen software platform that “will unite every major system from propulsion to infotainment and safety on a single, high-speed compute core,” according to Barra. The hope is that this approach not only cuts down on wiring and simplifies manufacturing, but also makes Chevys and Cadillacs more easily updatable and better-equipped for the self-driving future.

In that sense, it’s not about the wires. It’s about all the trends that have come to dominate electric vehicles — affordability, functionality, and autonomy — colliding head-on.

Europeans have been “snow farming” for ages. Now the U.S. is finally starting to catch on.

February 2015 was the snowiest month in Boston’s history. Over 28 days, the city received a debilitating 64.8 inches of snow; plows ran around the clock, eventually covering a distance equivalent to “almost 12 trips around the Equator.” Much of that plowed snow ended up in the city’s Seaport District, piled into a massive 75-foot-tall mountain that didn’t melt until July.

The Seaport District slush pile was one of 11 such “snow farms” established around Boston that winter, a cutesy term for a place that is essentially a dumpsite for snow plows. But though Bostonians reviled the pile — “Our nightmare is finally over!” the Massachusetts governor tweeted once it melted, an event that occasioned multiple headlines — the science behind snow farming might be the key to the continuation of the Winter Olympics in a warming world.

The number of cities capable of hosting the Winter Games is shrinking due to climate change. Of 93 currently viable host locations, only 52 will still have reliable winter conditions by the 2050s, researchers found back in 2024. In fact, over the 70 years since Cortina d’Ampezzo first hosted the Olympic Games in 1956, February temperatures in the Dolomites have warmed by 6.4 degrees Fahrenheit, according to Climate Central, a nonprofit climate research and communications group. Italian organizers are expected to produce more than 3 million cubic yards of artificial snow this year to make up for Mother Nature’s shortfall.

But just a few miles down the road from Bormio — the Olympic venue for the men’s Alpine skiing events as well as the debut of ski mountaineering next week — is the satellite venue of Santa Caterina di Valfurva, which hasn’t struggled nearly as much this year when it comes to usable snow. That’s because it is one of several European ski areas that have begun using snow farming to their advantage.

Like Ruka in Finland and Saas-Fee in Switzerland, Santa Caterina plows its snow each spring into what is essentially a more intentional version of the Great Boston Snow Pile. Using patented tarps and siding created by a Finnish company called Snow Secure, the facilities cover the snow … and then wait. As spring turns to summer, the pile shrinks, not because it’s melting but because it’s becoming denser, reducing the air between the individual snowflakes. In combination with the pile’s reduced surface area, this makes the snow cold and insulated enough that not even a sunny day will cause significant melt-off. (Neil DeGrasse Tyson once likened the phenomenon to trying to cook an entire potato with a lighter; successfully raising the inner temperature of a dense snowball, much less a gigantic snow pile, requires more heat.)

Shockingly little snow melts during storage. Snow Secure reports a melt rate of 8% to 20% on piles that can be 50,000 cubic meters in size, or the equivalent of about 20 Olympic swimming pools. When autumn eventually returns, ski areas can uncover their piles of farmed snow and spread it across a desired slope or trail using snowcats, specialized groomers that break up and evenly distribute the surface. For Santa Caterina, the goal was to store enough to make a nearly 2-mile-long cross-country trail — no need to wait for the first significant snowfall of the season, which creeps later and later every year.

“In many places, November used to be more like a winter month,” Antti Lauslahti, the CEO of Snow Secure, told me. “Now it’s more like a late-autumn month; it’s quite warm and unpredictable. Having that extra few weeks is significant. When you cannot open by Thanksgiving or Christmas, you can lose 20% to 30% of the annual turnover.”

Though the concept of snow farming is not new — Lauslahti told me the idea stems from the Finnish tradition of storing snow over the summer beneath wood chips, once a cheap byproduct of the local logging industry — the company's polystyrene mat technology, which helps to reduce summer melt, is. Now that the technique is patented, Snow Secure has begun expanding into North America with a small team. The venture could prove lucrative: Researchers expect that by the end of the century, as many as 80% of the downhill ski areas in the U.S. will be forced to wait until after Christmas to open, potentially resulting in economic losses of up to $2 billion.

While there have been a few early adopters of snow farming in Wisconsin, Utah, and Idaho, the number of ski areas in the United States using the technique remains surprisingly low, especially given its many other upsides. In the States, the most common snow management system is the creation of artificial snow, which is typically water- and energy-intensive. Snow farming not only avoids those costs — which can also have large environmental tolls, particularly in the water-strapped West — but the super-dense snow farming produces is “really ideal” for something like the Race Centre at Canada’s Sun Peaks Resort, where top athletes train. Downhill racers “want that packed, harder, faster snow,” Christina Antoniak, the area’s director of brand and communications, told me of the success of the inaugural season of snow farming at Sun Peaks. “That’s exactly what stored snow produced for that facility.”

The returns are greatest for small ski areas, which are also the most vulnerable to climate change. While the technology is an investment — Antoniak ballparked that Sun Peaks spent around $185,000 on Snow Secure’s siding — the money goes further at a smaller park. At somewhere like Park City Mountain in Utah, stored snow would cover only a small portion of the area’s 140 miles of skiable routes. But it can make a major difference for an area down the road like the Soldier Hollow Nordic Center, which has a more modest 20 miles of cross-country trails.

In fact, the 2025-2026 winter season will be the Nordic Center’s first using Snow Secure’s technology. Luke Bodensteiner, the area’s general manager and chief of sport, told me that alpine ski areas are “all very curious to see how our project goes. There is a lot of attention on what we do, and if it works out satisfactorily, we might see them move into it.”

Ensuring a reliable start to the ski season is no small thing for a local economy; jobs and travel plans rely on an area being open when it says it will be. But for the Soldier Hollow Nordic Center, the stakes are even higher: The area is one of the planned host venues of the 2034 Salt Lake City Winter Games. “Based on historical weather patterns, our goal is to be able to make all the snow that we need for the entire Olympic trail system in two weeks,” Bodensteiner said, adding, “We envision having four or five of these snow piles around the venue in the summer before the Olympic Games, just to guarantee — in a worst case scenario — that we’ve got snow on the venue.”

Antoniak, at Canada’s Sun Peaks, also told me that their area has been a bit of a “guinea pig” when it comes to snow farming. “A lot of ski areas have had their eyes on Sun Peaks and how [snow farming is] working here,” she told me. “And we’re happy to have those conversations with them, because this is something that gives the entire industry some more resiliency.”

Of course, the physics behind snow farming has a downside, too. The same science saving winter sports is also why that giant, dirty pile of plowed snow outside your building isn’t going anywhere anytime soon.

Current conditions: A train of three storms is set to pummel Southern California with flooding rain and up to 9 inches mountain snow • Cyclone Gezani just killed at least four people in Mozambique after leaving close to 60 dead in Madagascar • Temperatures in the southern Indian state of Kerala are on track to eclipse 100 degrees Fahrenheit.

What a difference two years makes. In April 2024, New York announced plans to open a fifth offshore wind solicitation, this time with a faster timeline and $200 million from the state to support the establishment of a turbine supply chain. Seven months later, at least four developers, including Germany’s RWE and the Danish wind giant Orsted, submitted bids. But as the Trump administration launched a war against offshore wind, developers withdrew their bids. On Friday, Albany formally canceled the auction. In a statement, the state government said the reversal was due to “federal actions disrupting the offshore wind market and instilling significant uncertainty into offshore wind project development.” That doesn’t mean offshore wind is kaput. As I wrote last week, Orsted’s projects are back on track after its most recent court victory against the White House’s stop-work orders. Equinor's Empire Wind, as Heatmap’s Jael Holzman wrote last month, is cruising to completion. If numbers developers shared with Canary Media are to be believed, the few offshore wind turbines already spinning on the East Coast actually churned out power more than half the time during the recent cold snap, reaching capacity factors typically associated with natural gas plants. That would be a big success. But that success may need the political winds to shift before it can be translated into more projects.

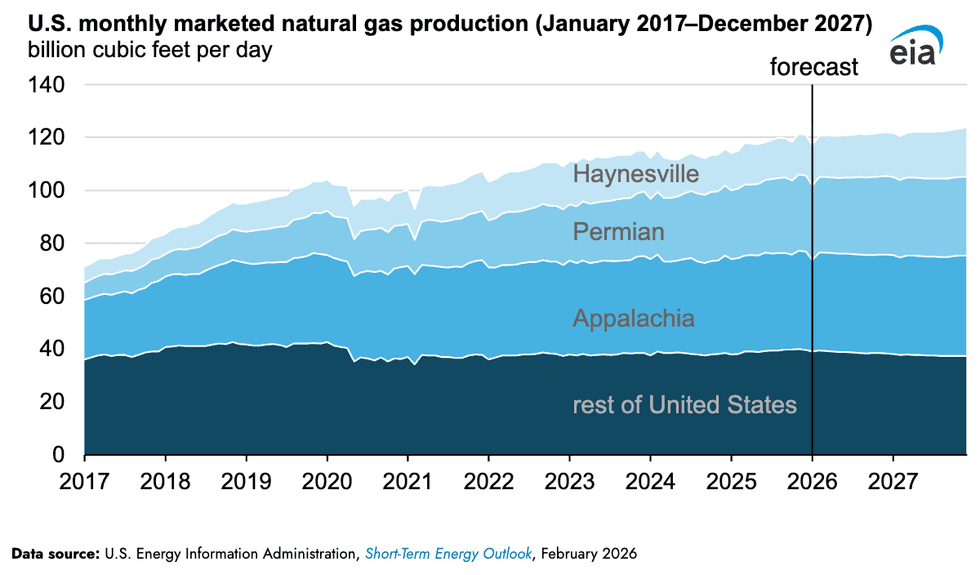

President Donald Trump’s “drill, baby, drill” isn’t moving American oil extractors, whose output is set to contract this year amid a global glut keeping prices low. But production of natural gas is set to hit a record high in 2026, and continue upward next year. The Energy Information Administration’s latest short-term energy outlook expects natural gas production to surge 2% this year to 120.8 billion cubic feet per day, from 118 billion in 2025 — then surge again next year to 122.3 billion cubic feet. Roughly 69% of the increased output is set to come from Appalachia, Louisiana’s Haynesville area, and the Texas Permian regions. Still, a lot of that gas is flowing to liquified natural gas exports, which Heatmap’s Matthew Zeitlin explained could raise prices.

The U.S. nuclear industry has yet to prove that microreactors can pencil out without the economies of scale that a big traditional reactor achieves. But two of the leading contenders in the race to commercialize the technology just crossed major milestones. On Friday, Amazon-backed X-energy received a license from the Nuclear Regulatory Commission to begin commercial production of reactor fuel high-assay low-enriched uranium, the rare but potent material that’s enriched up to four times higher than traditional reactor fuel. Due to its higher enrichment levels, HALEU, pronounced HAY-loo, requires facilities rated to the NRC’s Category II levels. While the U.S. has Category I facilities that handle low-enriched uranium and Category III facilities that manage the high-grade stuff made for the military, the country has not had a Category II site in operation. Once completed, the X-energy facility will be the first, in addition to being the first new commercial fuel producer licensed by the NRC in more than half a century.

On Sunday, the U.S. government airlifted a reactor for the first time. The Department of Defense transported one of Valar Atomics’ 5-megawatt microreactors via a C-17 from March Air Reserve Base in California to Hill Air Force Base in Utah. From there, the California-based startup’s reactor will go to the Utah Rafael Energy Lab in Orangeville, Utah, for testing. In a series of posts on X, Isaiah Taylor, Valar’s founder, called the event “a groundbreaking unlock for the American warfighters.” His company’s reactor, he said, “can power 5,000 homes or sustain a brigade-scale” forward operating base.

Sign up to receive Heatmap AM in your inbox every morning:

After years of attempting to sort out new allocations from the dwindling Colorado River, negotiators from states and the federal government disbanded Friday without a plan for supplying the 40 million people who depend on its waters. Upper-basin states Colorado, Utah, Wyoming, and New Mexico have so far resisted cutting water usage when lower-basin states California, Arizona, and Nevada are, as The Guardian put it, “responsible for creating the deficit” between supply and demand. But the lower-basin states said they had already agreed to substantial cuts and wanted the northern states to share in the burden. The disagreement has created an impasse for months; negotiators blew through deadlines in November and January to come up with a solution. Calling for “unprecedented cuts” that he himself described as “unbelievably harsh,” Brad Udall, senior water and climate research scientist at Colorado State University’s Colorado Water Center, said: “Mother Nature is not going to bail us out.”

In a statement Friday, Secretary of the Interior Doug Burgum described “negotiations efforts” as “productive” and said his agency would step in to provide guidelines to the states by October.

Europe’s “regulatory rigidity risks undermining the momentum of the hydrogen economy. That, at least, is the assessment of French President Emmanuel Macron, whose government has pumped tens of billions of euros into the clean-burning fuel and promoted the concept of “pink hydrogen” made with nuclear electricity as the solution that will make energy technology take off. Speaking at what Hydrogen Insight called “a high-level gathering of CEOs and European political leaders,” Macron, who is term-limited in next year’s presidential election, said European rules are “a crazy thing.” Green hydrogen, the version of the fuel made with renewable electricity, remains dogged by high prices that the chief executive of the Spanish oil company Repsol said recently will only come down once electricity rates decrease. The Dutch government, meanwhile, just announced plans to pump 8 billion euros, roughly $9.4 billion, into green hydrogen.

Kazakhstan is bringing back its tigers. The vast Central Asian nation’s tiger reintroduction program achieved record results in reforesting an area across the Ili River Delta and Southern Balkhash region, planting more than 37,000 seedlings and cuttings on an area spanning nearly 24 acres. The government planted roughly 30,000 narrow-leaf oleaster seedlings, 5,000 willow cuttings, and about 2,000 turanga trees, once called a “relic” of the Kazakh desert. Once the forests come back, the government plans to eventually reintroduce tigers, which died out in the 1950s.