You’re out of free articles.

Log in

To continue reading, log in to your account.

Create a Free Account

To unlock more free articles, please create a free account.

Sign In or Create an Account.

By continuing, you agree to the Terms of Service and acknowledge our Privacy Policy

Welcome to Heatmap

Thank you for registering with Heatmap. Climate change is one of the greatest challenges of our lives, a force reshaping our economy, our politics, and our culture. We hope to be your trusted, friendly, and insightful guide to that transformation. Please enjoy your free articles. You can check your profile here .

subscribe to get Unlimited access

Offer for a Heatmap News Unlimited Access subscription; please note that your subscription will renew automatically unless you cancel prior to renewal. Cancellation takes effect at the end of your current billing period. We will let you know in advance of any price changes. Taxes may apply. Offer terms are subject to change.

Subscribe to get unlimited Access

Hey, you are out of free articles but you are only a few clicks away from full access. Subscribe below and take advantage of our introductory offer.

subscribe to get Unlimited access

Offer for a Heatmap News Unlimited Access subscription; please note that your subscription will renew automatically unless you cancel prior to renewal. Cancellation takes effect at the end of your current billing period. We will let you know in advance of any price changes. Taxes may apply. Offer terms are subject to change.

Create Your Account

Please Enter Your Password

Forgot your password?

Please enter the email address you use for your account so we can send you a link to reset your password:

Rob and Jesse talk with John Henry Harris, the cofounder and CEO of Harbinger Motors.

You might not think that often about medium-duty trucks, but they’re all around you: ambulances, UPS and FedEx delivery trucks, school buses. And although they make up a relatively small share of vehicles on the road, they generate an outsized amount of carbon pollution. They’re also a surprisingly ripe target for electrification, because so many medium-duty trucks drive fewer than 150 miles a day.

On this week’s episode of Shift Key, Rob and Jesse talk with John Henry Harris, the cofounder and CEO of Harbinger Motors. Harbinger is a Los Angeles-based startup that sells electric and hybrid chassis for medium-duty vehicles, such as delivery vans, moving trucks, and ambulances.

Rob, John, and Jesse chat about why medium-duty trucking is unlike any other vehicle segment, how to design an electric truck to last 20 years, and how President Trump’s tariffs are already stalling out manufacturing firms. Shift Key is hosted by Jesse Jenkins, a professor of energy systems engineering at Princeton University, and Robinson Meyer, Heatmap’s executive editor.

Subscribe to “Shift Key” and find this episode on Apple Podcasts, Spotify, Amazon, YouTube, or wherever you get your podcasts.

You can also add the show’s RSS feed to your podcast app to follow us directly.

Here is an excerpt from our conversation:

Robinson Meyer: What is it like building a final assembly plant — a U.S. factory — in this moment?

John Harris: I would say lots of people talk about how excited they are about U.S. manufacturing, but that's very different than putting their money where their mouth is. Building a final assembly line, like we have — our team here is really good, that they made it feel not that hard. The challenge is the whole supply chain.

If we look at what we build here in-house at Harbinger, we have a final assembly line where we bolt parts together to make chassis. We also have two sub-component assembly lines where we take copper and make motors, and where we take cells and make batteries. All three of those lines work pretty well. We're pumping out chassis, and they roll out the door, and we sell them to people, which is great. But it’s all the stuff that goes into those, that's the most challenging. There's a lot of trade policy at certain hours of the day, on certain days of the week — depending on when we check — that is theoretically supposed to encourage us manufacturing.

But it's really not because of the volatility. It costs us an enormous amount to build the supply chain, to feed these lines. And when we have volatile trade policy, our reaction, and everyone else's reaction, is to just pause. It’s not to spend more money on U.S. manufacturing, because we were already doing that. We were spending a lot on U.S. manufacturing as part of our core approach to manufacturing.

The latest trade policy has caused us to spend less money on U.S. manufacturing — not more, because we're unclear on what is the demand environment going to be, what is the policy going to be next week? We were getting ready to make major investments to take certain manufacturing tasks in our supply chain out of China and move them to Mexico, for example. Now we’re not. We were getting ready to invest in certain kinds of automation to do things in house, and now we're waiting. So the volatility is dramatically shrinking investment in US manufacturing, including ours.

Meyer: And can you just explain, why did you make that decision to pause investment and how does trade policy affect that decision?

Harris: When we had 25% tariffs on China, if we take content out of China and move it to Mexico, we break even — if that. We might still end up underwater. That's because there's better automation in China. There's much higher labor productivity. And — this one is always shocking to people — there’s lower logistics costs. When we move stuff from Shenzhen to our factory, in many cases it costs us less than moving shipments from Monterey.

Mentioned:

CalStart’s data on medium-duty electric trucks deployed in the U.S.

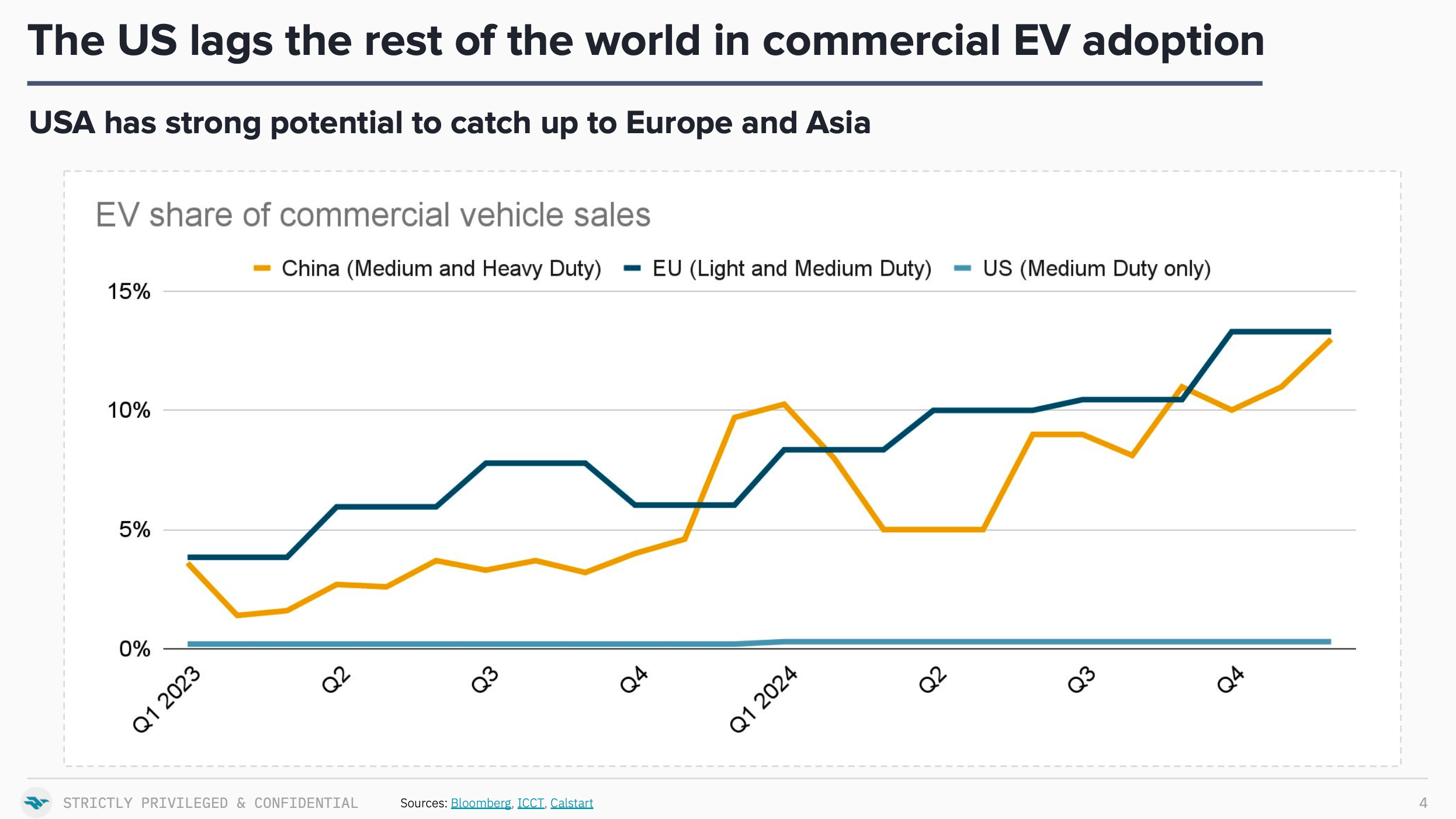

Here’s the chart that John showed Rob and Jesse:

It draws on data from Bloomberg in China, the ICCT, and the Calstart ZET Dashboard in the United States.

Jesse’s case for EVs with gas tanks — which are called extended range electric vehicles

Log in

To continue reading, log in to your account.

Create a Free Account

To unlock more free articles, please create a free account.

This transcript has been automatically generated.

Shift Key is hosted by Robinson Meyer, the founding executive editor of Heatmap News.

Subscribe to “Shift Key” and find this episode on Apple Podcasts, Spotify, Amazon, or wherever you get your podcasts.

You can also add the show’s RSS feed to your podcast app to follow us directly.

Robinson Meyer:

[1:26] Hi, I’m Robinson Meyer, and you are listening to Shift Key, Heatmap’s podcast about decarbonization and the shift away from fossil fuels. It is Monday, March 2. Over the weekend, the United States and Israel launched a new war on Iran, killing its Supreme Leader and bombing hundreds of targets across the country. The war is a big deal for the United States, for Iran, for the Middle East, and for the global economy. And even though it was preceded by the largest buildup of U.S. military equipment in the region since 2003, it was still, in a way, surprising. There hasn’t really been any effort to sell the war to the American people. It’s still not clear that it was legal or constitutional. And President Trump has been hazy about his goals for the conflict.

Robinson Meyer:

[2:06] For our purposes, though, here at Shift Key, the war is going to have big implications for the world’s energy markets in the short term and the long term. Like all geopolitical shocks, it is going to shape how countries make decisions about energy long after this particular conflict ends. And the longer this conflict goes, the deeper its consequences could be. So for today’s episode of Shift Key, I wanted to get our bearings on this new war and what it could mean. Our guest today is Gregory Brew. He’s an analyst with the Eurasia Group’s energy, climate, and resources team, focusing on the geopolitics of oil and gas. He serves as the group’s country analyst for Iran. And he’s an historian of modern Iran, oil and U.S. foreign policy, as well as the author of two books about the subject. He’s going to walk us through what has happened so far, just how long this conflict could go on and what it will mean for energy. Greg, welcome to Shift Key.

Gregory Brew:

[2:56] Thanks for having me on.

Robinson Meyer:

[2:58] Can you start by giving us a macro picture of what has happened over the past 72 hours at this point?

Gregory Brew:

[3:05] Sure thing.

Gregory Brew:

[3:08] Early Saturday morning local time, so late in the evening on Friday night here in the United States, the U.S. and Israel launched a significant military operation against Iran. In the past 48 hours, the U.S. and Israel have bombed probably more than a thousand targets inside Iran. These are mostly military targets. Iran’s ballistic missiles, elements of its military infrastructure inside the country, its navy, its naval assets close to the Persian Gulf, all have come under significant fire. In addition, Israel has specifically targeted members of Iran’s leadership. Supreme Leader Ali Khamenei is confirmed dead. Other members of the leadership have also been assassinated. There are other members that their fates remain unknown. In response, Iran has fired a large number of missiles and drones at U.S. bases, at Israel. Somewhat surprisingly, however, many of Iran’s missiles and drones are being fired at Gulf Arab states. The UAE has come under intense bombardment. Bahrain, Saudi Arabia, Kuwait, even Oman, which is a state that’s pretty friendly to Iran, and Qatar all have come under attack from Iran’s drones and missiles. The impact to energy so far, Iran kind of informally declared the Strait of Hormuz closed in the first 12 hours of the conflict.

Gregory Brew:

[4:19] This hasn’t really been followed up with any official action. There haven’t really been many tanker attacks by Iran, but tanker traffic through the strait has come to an almost complete halt. Oil tankers, LNG tankers, tankers carrying refined products, most of them have kind of frozen in place as they await for some clarity as to the situation and as to the risk. Oil prices rose sharply. Sunday night when markets opened, the price of oil went up from about $73 a barrel to about $80 a barrel. Then it fell slightly. It’s at around $78, $79 now. Equally important, I think natural gas prices have increased sharply in various regional markets. The price of natural gas in Europe shot up dramatically today on news that Qatar was going to be shutting off gas production. That’s how the energy story has kind of played out. I should note at the time we’re recording, the war is still ongoing. U.S. and Israel still bombing Iran. Iran is still firing back. Doesn’t look to be concluding anytime soon.

Robinson Meyer:

[5:13] I want to get to the energy picture in a second, but let’s talk about what has happened as far as we can tell from the places that have been bombed from the kind of targets that have been chosen by the U.S. and Israel. Do we have a sense of what their goals are here?

Gregory Brew:

[5:28] We have a sense. I’ll say that. The president has made a number of addresses to the nation where he frames this operation in two ways. One, this is the U.S. and Israel using military power to significantly reduce the threat that Iran poses to U.S. interests, to U.S. bases, and to U.S. allies. In the run-up to this war, there was a lot of attention being paid to Iran’s nuclear program. That program was mostly destroyed in the war of last June, although elements of it remain. However, there were quite a few comments from U.S. officials and a lot being said in private, which suggested that the key U.S. and Israeli concern was not Iran’s nuclear program, but its stockpile of ballistic missiles. Iran is in kind of an interesting state as far as its military. It’s been under sanction for so long. Its ability to build up a conventional

Gregory Brew:

[6:16] military has been pretty curtailed. Like it doesn’t have advanced jet fighters. It doesn’t have a lot of advanced sophisticated military hardware. Where its military is kind of inferior as far as the region is concerned. What it does have, what it’s spent a lot of money, a lot of time and a lot of resources on, is developing a large number of advanced ballistic missiles. And so that’s been, I would say, the single largest focus of the operation. Israel and the U.S. taking aim at Iran’s missiles, trying to blow them up, trying to blow up the factories where these missiles are made, the stockpiles where the missiles are kept, the launchers that Iran uses. That’s the sort of military goal. Trump has been talking about regime change.

Gregory Brew:

[6:53] But the way he’s been framing it is interesting. He says that the U.S. supports regime change in Iran, but that it has to come through the actions of the Iranian people, that the U.S. won’t put boots on the ground, that there’s not going to be a ground invasion of Iran. So I think right now, I think the goal for the U.S. is somewhat open ended. I think they’re going to continue to bomb Iran so long as they see means to do so to keep degrading it to keep damaging it. If that ends with a new regime, great. But at the end of the day, so long as Iran is significantly weakened. And as so long as the threat that Iran poses to the U.S. and the region and to Israel has been significantly reduced, I think that’s enough of a win for at least the president to claim victory.

Robinson Meyer:

[7:30] What would that mean for Iran to be as a state that would have no more military, that basically lost its entire elite and senior leadership structure and has faced these large protests? Like, do we have any sense of what this would mean for the Iranian people?

Gregory Brew:

[7:49] Well, for the Iranian people, nothing good in the short term. Any kind of war puts immense strain on a country, on a people, on a society. We saw that in the war of June of last year. I talked to people in Iran quite frequently. And apart from the political sense, the sense of anger at the regime, the discontent that’s widespread at this point, there was a lot of trauma from the experience of being bombed for two weeks. And right now they’re being bombed not only by Israel, but by the global superpower, the United States. And it’s a campaign of bombing that doesn’t appear to be coming to an end anytime soon. This is going to do additional damage to Iran’s economy.

Gregory Brew:

[8:26] As far as the regime is concerned, there were plans that had been put in place even last June during the war with Israel to manage in the event of Khamenei’s sudden death by decapitation or assassination strike. So his death has not been a body blow to the regime leadership. There’s already a process that’s in motion to pick a new supreme leader. They’re likely to pick one in the coming days, they appear to be doing so quite quickly. That is their way of signaling that, hey, nothing’s going to change from this, right? Regime’s not going anywhere, the Islamic Republic will continue to stand tall. If Trump sees victory in blowing up most of Iran’s military, the Islamic Republic will see victory in surviving that conflict. So long as they emerge with their position more or less intact, which they’re likely to do. What we saw in January was a regime that has no compunction about using lethal force against its own people. The security forces are still in their control. The police are still in their control. The army hasn’t revolted. The leadership hasn’t cracked. So long as that remains the case, I think this war ends with the Islamic Republic still standing,

Gregory Brew:

[9:26] more or less, but in heavily battered form.

Robinson Meyer:

[9:29] Do we have any sense of how this ends on the U.S. side?

Gregory Brew:

[9:34] I think this ends when Trump decides it ends. Right now, there have been some recent comments from the president that sound defiant, that sound resistant to bringing the war to an end. I would hesitate to say, however, whether this administration wants this war to go on for more than a few weeks, right? A longer war keeps oil prices high. A longer war threatens further damage to the U.S. position in the region. Iranian missiles and drones are getting through. They are causing damage, not only to the U.S. bases, but to GCC states. And there’s only so long that the Saudis, the Emiratis, the Qataris are going to want to continue to be hit by Iranian drones. They’re going to want this war to end fairly quickly. As for Trump, if you look at past experience, the wars that he’s been able to deliver, the military interventions that he’s carried out and been able to frame as wins have been short. They’ve been decisive. They haven’t turned into prolonged conflicts. And I think that’s where his head is going to be, try to pull a victory out of something that lasts only a week or two. But right now, he’s signaling that he’s willing to go the distance. Part of that is in response to the Iranians, because the Iranians are treating this like a battle of wills. We can go longer than you, we can keep shooting, we can take the hit. But so long as we continue to cause damage and pain to you, it’s going to be in your interest to wrap this up sooner rather than later.

Robinson Meyer:

[10:46] It’s interesting because there’s two different Trumpian instincts here, or two different Trumpian tendencies. The first is to basically push through with a policy until he reverses it. And a longtime political strength of Trump’s has been that he can reverse any policy at the drop of a hat. And there’s no embarrassment, there’s no shame, that policy is over, and we move on.

Robinson Meyer:

[11:12] And the second, the second tendency here is that, as you were saying, he hasn’t been afraid to break norms, right? And we saw this at the end of his first term with the assassination of Soleimani in Iraq. We saw this term with the operation of Venezuela. And in Venezuela, there was a sense that, oh, my gosh, is the U.S. Now involved in a Latin American country? Are we involved in a process of regime change? And it turned out no, because seemingly they had already back-channeled with Delcy Rodriguez and she was going to be basically a U.S. puppet in the new kind of quasi-regime that emerged. But here it doesn’t seem like there is either a – if they had a goal, they’ve already accomplished it, which is decapitating the Supreme Leader. And if they had a kind of a back channeled puppet leader to put in charge of the country, Trump actually said yesterday that their second or third choices to lead the country had been killed in these military strikes. And so he didn’t have like a candidate. Now, of course, he wouldn’t reveal this, but he didn’t have some kind of candidate ready to go to take over Iran, who could then deal with the U.S. and be addressed to by the U.S.

Gregory Brew:

[12:23] Yeah, so I think the president is putting out a lot of different narratives around this, as far as what the U.S. goal is, whether it is meant to collapse the regime. I mean, he’s been saying things like, the IRGC will surrender, they’ll hand their weapons over to the people, which is a really nice idea. But it’s very difficult to see that happening in reality. It’s very difficult to see how that would happen. A Venezuela style transition is somewhat more plausible, or it could have been somewhat more plausible. But only really in a scenario where the U.S. and Israel deescalate following the assassination of Khamenei and they’re not doing that. They’re continuing to bomb Iran. They’re maintaining the pressure. Whether the United States is communicating with members of the Iranian leadership is beyond me. I couldn’t speculate as to that. I do see it as being plausible that they’re communicating to the Iranians, if you want this to stop, give up X, Y, and Z. We’ll keep doing this unless you surrender, unless you capitulate. And the Iranians are going to have a very strong sense to not do that. Expecting them to surrender misreads the Iranians, both in terms of their position, but also in terms of their ideology and their characteristics. They’re not going to back down.

Robinson Meyer:

[13:26] Can you walk us through some scenarios here? So what would a 10-day, I think there’s been some reference from the president, from others, that this could be a 10-day campaign. There’s been other timeframes that are thrown around. We’re going to get to them. But what would a 10-day campaign here look like, given that I guess we’re already on day three?

Gregory Brew:

[13:45] Yeah, we’re on day three. So the opening salvos included the most significant targets in Iran’s military. Its navy was heavily targeted in the opening days of the strikes. Obviously, Khamenei was hit first. I think he may very well have been the first target. There’s been some reporting to suggest that the Israelis decided to move forward the timeline of strikes because they saw an opportunity to strike at Khamenei, who is generally a fairly elusive figure. He spends a lot of time in secure locations. In this instance, he was at his residence. It was daylight, he was exposed, and they decided to go. This expanding over the next week, you know, the Americans, the Israelis could continue to strike at missile facilities, a lot of these facilities are hardened, they could keep the fight going so that they can get the Iranians to deploy their missiles so that the missiles can be destroyed in the air or on the ground. I think some of this will start to look a little bit like a war of attrition. By the end of the week, that’s probably how the Iranians are thinking about it. They’re shifting or likely will shift from firing lots of missiles to firing lots of drones, which they can do so more easily.

Gregory Brew:

[14:41] They have a lot more of them. They have somewhere in the realm or had somewhere in the realm of 2,000 short range and 2,000 medium range ballistic missiles when the war began, they have thousands of drones, and they can keep firing them in large numbers. So if the Iranian goal is to impose pain and cost to the U.S. to force them to deescalate, then the Iranians will keep shooting at GCC targets at U.S. bases and at Israel, so long as they can. For the Americans after 10 days, they probably will have done as much damage as they could do to Iran’s capabilities. Israel has also targeted internal security forces, police, the Basij paramilitaries that the regime uses to put down dissent. Again, I don’t know if the operation is actually aiming at regime change, but hitting targets like this will undermine the regime, will weaken its control on Iran’s internal security, will cause Iran to exit this conflict in a weakened state. That serves Israel’s interests, even if it doesn’t end up with the regime collapsing. I would expect more strikes like those in the days to come.

Robinson Meyer:

[15:36] Last question, and then we’ll move to energy, which is ostensibly the topic we’re talking about. What would a five-week campaign look like? Briefly, because that’s the other time frame I think we’ve heard from the president.

Gregory Brew:

[15:49] Yeah. I mean, a campaign could last five weeks. I don’t know if it maintains the same level of intensity because they will start to run low on targets. A five week campaign would likely involve more strikes on internal security forces, on leadership, on the apparatus of the regime. I think a five week campaign would be more geared around making the Islamic Republic’s position inside Iran untenable, either creating the environment for protests, creating the environment for internal fracturing, so that you get some kind of shift in the leadership towards individuals who are willing to capitulate, who are willing to come to terms with the United States. That’s, I think, what a five-week campaign would look like. But I also think a five-week campaign wouldn’t be carried on with the same level of intensity. The U.S. would continue strikes, probably at a lower rate. It would look, again, a little bit more like a war of attrition with the Iranians continuing to shoot back as far as they are able. The problem with a five-week campaign for me is that the political costs to Trump mount the longer this war continues, right? It keeps oil prices high, keeps energy prices high, the risk of U.S. casualties, the risk of damage. The longer he goes without pulling a win out of this, I think the weaker he looks.

Robinson Meyer:

[18:28] Something I’ve been thinking about is that the U.S. posture during this war, which is kind of all tactics, no strategy, is kind of derived from Israeli military approaches. But there was no effort to build up a constituency in the U.S. for this war. There’s no sense of existential risk like there is in Israel, around Iran, in the U.S., around Iran. And so ... to some degree, there are Israeli tactics and there is an Israeli posture that’s being borrowed for U.S. operations in this conflict. But there’s none of the domestic politics that makes that possible in the U.S.

Gregory Brew:

[19:07] Yeah, I mean, absolutely. Iran matters a great deal more to Israel than Iran matters to the United States, insofar as Iran matters to the United States. I do think, though, it needs to be remembered that the U.S. is committed to maintaining its position in military hegemony in the Middle East. And Iran is a threat to that position. It’s a threat to U.S. bases in the region. It’s a threat to U.S. partners in the Gulf. It’s obviously a threat to Israel. And Israel is a close U.S. ally. This is a relationship that’s come under political pressure lately. But as far as strategic cooperation, as far as the alignment of interests,

Gregory Brew:

[19:40] when Israel and the United States look at the region, they tend to have very, very similar views. And a key aspect of that view is Iran is a threat. So as far as the approach to Iran using military force, there has been a shift in the last two years. Some of that is Iran’s own doing. Iran chose to escalate in April of 2024 when it launched hundreds of missiles and drones at Israel for the first time ever. It was signaling that it was now willing to take direct military action against Israel. Israel responded by taking direct military action against Iran, and it has not gone well for the Iranians. In that sense, Trump is going further than any U.S. president has in the past. And he is following Israel’s lead to some extent. But I would hesitate to draw too much to say that there’s too much space between the Israeli and American positions as far as viewing Iran, viewing the region strategically. But certainly politically, no one in the country, no one in the U.S. is telling Trump a war with Iran is a national priority. A war with Iran is how you’re going to get your poll numbers up. A war with Iran is how we’re going to win the midterms. That does put constraints on how long the U.S. can continue this war and on how Trump is going to see any kind of upside from it.

Robinson Meyer:

[20:46] Nor has Trump tried to convince his coalition that a war with Iran is a national priority. But let’s talk about energy. I think the first place that people’s minds go when you’re talking about Iran, when you’re talking about the Strait of Hormuz, is oil. Why is the Strait of Hormuz particularly important to the global oil market? And then second of all, like what have we seen as the initial effects here?

Gregory Brew:

[21:09] So the Strait of Hormuz matters for three reasons. One, it is a very narrow waterway. So it is quite easy, theoretically, to block it.

Gregory Brew:

[21:19] Other waterways, even the Bab el-Mandab and the Red Sea, the Strait of Malacca, other strategic pathways through which large quantities of energy move are not so easily disrupted as the Strait of Hormuz. That’s reason number one. Reason number two, Iran. Iran is there. Iran frequently threatens to block the Strait of Hormuz, frequently threatens to close the Strait of Hormuz. It is a hostile actor vis-à-vis the other states in the region. We are now seeing proof of that, given that it is open fire on the GCC in a concerted way. That’s another reason why the Strait of Hormuz gets so much attention as far as the connection between the strait, the strait security and the situation in the global oil market. The third reason, I guess there are four reasons. The third reason is the volume of energy moving through the strait. It’s close to a fifth of global oil supply. It’s 20 million barrels a day, sometimes a little more. It’s a significant portion of the global LNG supply coming from Qatar has to pass through the Strait of Hormuz. A large quantity of refined products, metal distillates, condensates, fuel oil moves through the strait. So the volume affected by the strait being closed or disrupted or affected in some way is very, very large. Finally, fourth point, there’s nowhere else to go. You can’t go around the Strait of Hormuz. You have to go through it.

Gregory Brew:

[22:29] Tankers that can’t transit the strait or are blocked from doing so have no other options. There’s no Africa route as there was with the Red Sea disruption. So for those four reasons, the Strait of Hormuz gets a lot of attention. And it’s why it’s getting attention now. Although, interestingly enough, price of oil has responded, but has not moved so in a significant way, at least per some people’s expectations.

Robinson Meyer:

[22:51] Well, the theme of the year in oil so far has been that there’s a glut of oil. Or there’s at least a small glut of oil. We’ve kind of been dealing with that for a long time. And so I wonder if that is in some ways, one hesitates to call this good for oil markets, but it is kind of solving an issue for the market. Do you think oil is the most important energy product affected by this war?

Gregory Brew:

[23:15] Well, it’s certainly the largest in terms of volume, given how much oil moves through the strait. However, I think this could end up being a gas story as much as an oil story for two reasons. One, gas has already been physically affected. Just this morning, Qatar LNG put out a notice saying that it was halting production due to Iranian attacks on its facilities. Theoretically, this means that all Qatari LNG exports will be halted. And Qatar is among the top three global LNG producers. So if that happens, global LNG supply will be significantly constrained.

Gregory Brew:

[23:45] So far, there hasn’t been any significant constraints to oil supply. Tankers have paused in transiting the Strait of Hormuz, but physical disruptions haven’t yet occurred. The second reason is the state of the global gas market is tighter than the state of the global oil market. Oil is in a slight imbalance in supply versus demand. That’s been what has been keeping prices relatively low over the last six months, geopolitics notwithstanding. By comparison, gas inventories in Europe and Northeast Asia are fairly low as these countries are coming out of the winter months. So the effect of a Qatar shutoff or the effect of a significant disruption in LNG traffic through the strait, even if it is only short, could end up having fairly significant effect. Finally, prices, gas prices have shot up today much higher relative than to the increase in oil prices. So already the gas market is responding in a more significant way than the oil market has.

Robinson Meyer:

[24:34] Who will feel the effect of tighter and higher LNG markets and prices? I mean, is this primarily a Japan and Europe story? Is this something where in the U.S., I mean, we explored a lot of LNG, but would we expect those LNG prices to translate back into domestic gas prices?

Gregory Brew:

[24:50] I think gas prices in the U.S. are likely to remain fairly low. They may increase slightly as the average LNG price globally increases. But I think this will affect Europe, particularly as their inventories are somewhat lower than major Northeast Asia importers like Japan and South Korea. The Europeans are still getting over the long effects of the war in Ukraine, moving away from dependence on Russian gas. They’ve had to depend on LNG to a more considerable degree. So a disruption on this scale, if it proves lasting, could be quite bad for the affordability of energy in Europe. Europe’s not going to run out of gas, but it will be forced to pay more money for it. Finally, there could be a dynamic that we saw in 2022, where all other markets that can’t compete with the high prices that Europe is demanding feel the effects. Markets like Southeast Asia or South Asia will see perhaps less access to LNG if more cargos are being diverted to Europe to take advantage of the very healthy

Gregory Brew:

[25:41] arbitrage opportunities between Europe gas prices and those in the United States.

Robinson Meyer:

[25:45] What do you think we learned from the 2022 post-Ukraine energy shock that might be applied now? Like what emerged then that could affect what we’re about to see?

Gregory Brew:

[25:56] I think if this conflict does end up disrupting LNG exports in a significant way, where the disruption lasts more than a few days, where the prices rise and remain high, I think it will offer up a similar lesson to the war in 2022, which is that LNG can be very volatile. It can be very reliable, but during periods of intense geopolitical conflict with supplies like Qatar being affected by conflict, affected by security in the region, that ends up hitting consumers because it ends up, they end up having to shoulder much higher prices. They end up having to shoulder the burden of insecure energy. One of the arguments made against LNG over the last couple of years is that while it is, while it makes a lot of sense, the economics make a lot of sense. If it’s continually exposed to these kinds of volatile spikes, if geopolitics keeps the average price of gas much higher than that of coal or renewables, then ultimately LNG can’t compete with those alternative sources of supply. Even if the economics make sense, the geopolitics might not.

Robinson Meyer:

[26:54] Well, and this is what I was thinking. From some climate folks, I think there’s been a turn after this conflict, as there is after many conflicts, to say, look, this is why renewables are so important, because they don’t experience this price volatility in the same way that LNG does. The issue is coal also doesn’t really experience this price volatility. And frankly, many, many countries around the world, particularly those that suffer when LNG prices go up in sub-Saharan Africa and Southeast Asia, do actually have ample coal resources. And if they need to, they’ll learn from the Chinese example, as much as building solar and batteries is important, so is building a big coal fleet because you always have security of supply with coal.

Gregory Brew:

[27:35] Absolutely.

Robinson Meyer:

[27:36] Gregory Brew, thank you so much for joining us on Shift Key.

Gregory Brew:

[27:39] Thanks for having me back.

Robinson Meyer:

[27:42] Thanks so much for listening to this emergency episode of Shift Key. We’ll be continuing to cover the conflict at Heatmap News. That’s heatmap.news. Until then, Shift Key is a production of Heatmap News. Our editors are Jillian Goodman and Nico Lauricella. Multimedia editing and audio engineering is by Jacob Lambert and by Nick Woodbury. Our music is by Adam Kromelow. Thanks so much for listening and see you soon.

The U.S.-Israeli campaign will have, if anything, bigger implications for liquified natural gas.

The world’s second largest exporter of liquified natural gas is off the market. Qatar’s state-owned energy company announced Monday morning that its LNG production and export operations were halting “due to military attacks on QatarEnergy’s operating facilities,” including the Raf Laffan plant, which accounts for about 20% of global LNG supplies, according to Bloomberg.

This is very good news for U.S. LNG exporters and very bad news for anyone who’s in the market for seaborne natural gas imports.

Exports from Qatar largely go to Asia, with China as the dominant buyer, according to data from the investment bank Jefferies. Qatar has been exporting LNG since 1996, and is the world’s second largest exporter behind the United States, according to the U.S. Energy Information Administration.

Even before the strikes on Qatar’s natural gas infrastructure, all traffic through the Strait of Hormuz, the vital waterway linking Gulf oil and gas production to the rest of the world, had “effectively ceased for the time being” due to insurers withdrawing from the market and reports of some ships being attacked, according to the energy consulting firm Wood Mackenzie.

But the Strait of Hormuz only connects the Persian Gulf to the Arabian Sea. Its closure does nothing to obstruct passage through, say, the Sabine Pass, which connects Sabine Lake to the Gulf of Mexico, and is the heart of the U.S. LNG industry. With natural gas prices already shooting up, U.S. exporters appear to be in for a bonanza.

“If you’re talking to one of the buyers of LNG from Qatar in Asia and you still need LNG, you’re going to have to bid up somewhere else,” Ira Joseph, senior research associate at the Center on Global Energy Policy at Columbia University, told me. “Financially, this is really good for U.S. LNG. It’s a massive windfall for them.”

And, Joseph said, the crisis is unlikely to feed into domestic electricity prices. While a report issued by the Department of Energy toward the end of the Biden administration found that higher natural gas exports would lead to higher domestic prices for natural gas (and thus higher electricity prices), for the moment at least, export capacity is essentially maxed out, meaning that the increased demand for gas will translate largely into higher prices, not greater supply.

Shares of U.S. LNG exporters were accordingly up in early afternoon trading. Venture, which operates the Plaquemines and Calcasieu Pass export terminals in Louisiana, saw its share price rise some 14.5% as of 2 p.m. Monday. Shares in Cheniere Energy, which shipped America’s first LNG cargos in 2016 from Sabine Pass and has additional operations in Texas, were up around 5.5%.

The one U.S. natural gas export project scheduled to start up soon is, of all things, a QatarEnergy-ExxonMobil joint venture just on the other side of the Texas border from the Cheniere Sabine Pass facility. Production is expected to begin there this month.

And Qatar is also in the midst of planning to expand export capacity at home: QatarEnergy awarded engineering and construction contracts for its North Field West project, a move Jefferies had described as part and parcel of Qatar’s strategy of being “the lowest cost LNG producer, [which] remains focused on market share and is unwilling to adjust supply to market conditions.”

Now that loose supplier is off the market.

“Everybody will be competing for the same molecule of LNG. And that makes things very difficult,” Massimo Di Odoardo, Wood Mackenzie’s vice president of gas and LNG research, said in a webinar hosted by the firm.

“The gas energy market is structurally more volatile than the oil market. There is no such thing as strategic reserves. There is no such thing as spare capacity. Whenever there’s a shock in the market, the effect on prices is normally very strong, and this is a massive shock in terms of lack of supply,” he said.

Some of the most dramatic effects of this competition for LNG are likely to be felt in South and Southeast Asia, to which Qatar is a major exporter and where importers don’t have the same ability to withstand higher prices as they do in, say, South Korea or Japan.

Rich countries “will perhaps look for LNG from other sources to backfill the shortfall of debt supply, Di Odoardo said. “Countries like India, Pakistan, and Bangladesh might be less inclined to pay these very high prices at the moment.”

Joseph agreed with this view. Of Qatar’s big customers, Joseph said, Japan, China, Taiwan, and South Korea will likely hang in. But for poorer countries, “if prices get too high, you’re not going to buy the LNG,” he told me. “The loss of this much LNG is not going to be solved just through higher prices.”

The shock to energy prices has given many observers flashbacks to 2022, when Russia’s invasion of Ukraine helped tip Pakistan — which is very populous, very poor, and very reliant on energy imports — into an economic crisis. As that conflict unfolded, natural gas imports were redirected towards richer countries that could pay up, while poorer countries were left stranded in energy poverty.

The current shock to the LNG market, meanwhile, comes at a time when much of the world is rethinking its reliance on the United States, whether as a military partner or an economic one.

The whole scenario contains a distinct irony.

The United States escalated tensions with Iran into a full-scaled military operation with the goal of eliminating the Islamic Republic’s ballistic missiles and nuclear program and even overthrowing its ruling regime. In response, Iran has lashed out not just at the United States and Israel, but also at its Arab neighbors, including some of the world’s largest oil and gas producers. As a result of that escalation, U.S. energy exporters can expect increased profits in the short term, and the U.S. will likely see more sustained interest in economic partnerships in the medium to long term.

“In the grand scheme of geopolitical risks, this puts a bigger risk on the Middle East versus other regions, and has to be positive in terms of how U.S. energy looks in the global context,” Di Odoardo said.

Current conditions: Springlike weather is bringing rain from Texas to Michigan • A Saharan dust storm known as a calima is headed for Europe, threatening “blood rain” as far north as Luxembourg • The Greenlandic capital of Nuuk is poised for days of snow, but with limited accumulation.

The aerial assault the United States and Israel launched on Iran this past weekend is already sending oil prices upward. By Sunday evening, the price for West Texas Intermediate crude, the benchmark for the oil drilled in the U.S., had risen 2.78% to just over $67 per barrel. Brent crude, the benchmark typically used to measure Europe’s production, 2.87% to nearly $73 per barrel. Murban crude, the benchmark set out of Abu Dhabi, surged by more than 4% to north of $74. By rendering the Strait of Hormuz — the waterway between the United Arab Emirates and Iran through which 15% of global oil flows and which tapers to just 20 miles wide at its narrowest point — impassable, the conflict could send prices per barrel as high as $100 or more, the consultancy Wood Mackenzie warned Sunday night. “The key question is when do vessels re-establish export flows,” Alan Gelder, Wood Mackenzie’s senior vice president of refining, chemicals and oil markets, said in a statement. “No doubt, tanker rates and insurance will increase dramatically, but these costs would only be a small part of the oil price impact associated with a curtailment of oil flows if they last for more than a few days.”

The rise in prices began weeks ago as the biggest U.S. troop buildup in the Middle East since 2003 seemed to presage war. The market isn’t just reflecting a fear of an unpredictable and prolonged halt to tanker traffic through the Strait. Insurers are threatening to cancel policies on vessels that dare to pass the waterway right now, the Financial Times reported. Iranian attacks on buildings and infrastructure belonging to America’s Arab allies across the Persian Gulf suggests the rest of the region’s oil production could face damage. “Right next door, you’ve got Iraq, you’ve got Saudi Arabia, and you’ve got the Emirates and others who collectively are more like 20 million barrels per day. And that is obviously a much bigger deal,” Rory Johnston, petroleum analyst and author of Commodity Context, told Heatmap’s Matthew Zeitlin.

A North Dakota judge finalized a $345 million judgement against Greenpeace USA on Friday, ordering the American chapter of the famed activist group to pay out the damages from its protests against the construction of the Dakota Access Pipeline. The ruling came after judge James Gion decided in October to slash almost half the $667 million that a jury awarded developer Energy Transfer Partners a year ago. The Dallas-based company called the ruling an “important step in this legal process of holding Greenpeace accountable for its unlawful and damaging actions against us.” In its own statement, Greenpeace said, “this is not the end of the case — or Greenpeace USA.” Rather, the group said it will request a new trial and, if necessary, “appeal the decision to the North Dakota Supreme Court.” The organization, which has since its founding in 1971 embarked on audacious acts of protest to raise awareness about environmental destruction, cast its fight against the ruling as a battle to protect Americans’ First Amendment rights. “In the years since the Standing Rock protests, anti-protest laws have spread across the U.S. and the world. Two of the most important components of change and progress throughout human history — free speech and peaceful protest – have never been more endangered,” Greenpeace said in the statement. “We must defend those rights. Our future depends on it.”

Last year, the International Seabed Authority, a little known United Nations agency based in Jamaica, debated how to establish rules for giving private companies permits to collect mineral-rich nodules off the deep ocean floor in waters far from any country’s maritime borders. Under outside pressure from the U.S., which is not a signatory to the ISA and has vowed under the Trump administration to go it alone on deep-sea mining, countries failed to reach an agreement. When the body reconvenes this week in the capital city of Kingston, the head of the ISA is determined to finalize a plan. In an interview with The New York Times, ISA chief Leticia Caravalho promised to broker a deal this year, lest an area in international waters become what she called the Wild West. “The world agreed 30 years ago that this is an area that belongs to all of us, and we should go there collectively,” she said. Banning mining outright, as some countries (and groups such as Greenpeace) have called for, would only take money away from scientific research and delay setting strict environmental protections, she said. “Being able to make the rules before activity starts is unique in human history,” she said.

Sign up to receive Heatmap AM in your inbox every morning:

The 220-megawatt ACES Delta green hydrogen project in Utah is by far the largest in the U.S. Now it’s ready to launch. As of last week, all 40 of the electrolyzers at the facility were installed and fully operational, supplier HydrogenPro told the trade publication Hydrogen Insight. It’s a critical milestone for a sector facing mounting challenges as the federal tax credit known as 45V begins its earlier phase out next year and the Trump administration yanks funding for the two regional hubs meant to hasten deployment of green hydrogen technology. Not every project is panning out as well. In New York, the developer Plug Power announced plans to abandon a 120-megawatt plant and sell the land to a data center company.

There’s a lot going on in hydrogen, including entirely new colors added to the rainbow scheme that describes how the fuel is made. If you want a quick 101 guide, this episode of Heatmap's Shift Key podcast is a good place to start.

At this stage in the new nuclear race, the company that looks likely to deploy the first small modular reactor in North America is GE Vernova Hitachi Nuclear Energy, the U.S.-Japanese joint venture building its debut BWRX-300 at the Darlington nuclear plant in Ontario, Canada. The developer is set to build another one of the third-generation, 300-megawatt reactors at the Tennessee Valley Authority soon after, and, as I reported for Heatmap, received major funding from the Department of Energy last year to pull it off. Until now, five European countries have been considering buying their own BWRX-300s: Czechia, Estonia, Finland, Poland, and Sweden. Now add a sixth. Lithuania just signed onto a memorandum of understanding in Washington promising to assess the potential to deploy the reactor, according to World Nuclear News.

There is a bright spot for clean energy in the Middle East. In Iraq, the first 250-megawatt section of what’s designed to be a 1-gigawatt solar farm is expected to enter operation in the next few days after the facility’s transmission connection powered on for the first time. Located in the Basra region, site of some of the bloodiest battles of the Iraq war, the project is a joint venture between the French giant TotalEnergies, which has a 45% stake; the Basrah Oil Company, which commands 30% of the solar farm; and QatarEnergy, with 25%, according to Renewables Now.