You’re out of free articles.

Log in

To continue reading, log in to your account.

Create a Free Account

To unlock more free articles, please create a free account.

Sign In or Create an Account.

By continuing, you agree to the Terms of Service and acknowledge our Privacy Policy

Welcome to Heatmap

Thank you for registering with Heatmap. Climate change is one of the greatest challenges of our lives, a force reshaping our economy, our politics, and our culture. We hope to be your trusted, friendly, and insightful guide to that transformation. Please enjoy your free articles. You can check your profile here .

subscribe to get Unlimited access

Offer for a Heatmap News Unlimited Access subscription; please note that your subscription will renew automatically unless you cancel prior to renewal. Cancellation takes effect at the end of your current billing period. We will let you know in advance of any price changes. Taxes may apply. Offer terms are subject to change.

Subscribe to get unlimited Access

Hey, you are out of free articles but you are only a few clicks away from full access. Subscribe below and take advantage of our introductory offer.

subscribe to get Unlimited access

Offer for a Heatmap News Unlimited Access subscription; please note that your subscription will renew automatically unless you cancel prior to renewal. Cancellation takes effect at the end of your current billing period. We will let you know in advance of any price changes. Taxes may apply. Offer terms are subject to change.

Create Your Account

Please Enter Your Password

Forgot your password?

Please enter the email address you use for your account so we can send you a link to reset your password:

The same technology that powers your cell phone also helps expand the reach of renewable energy.

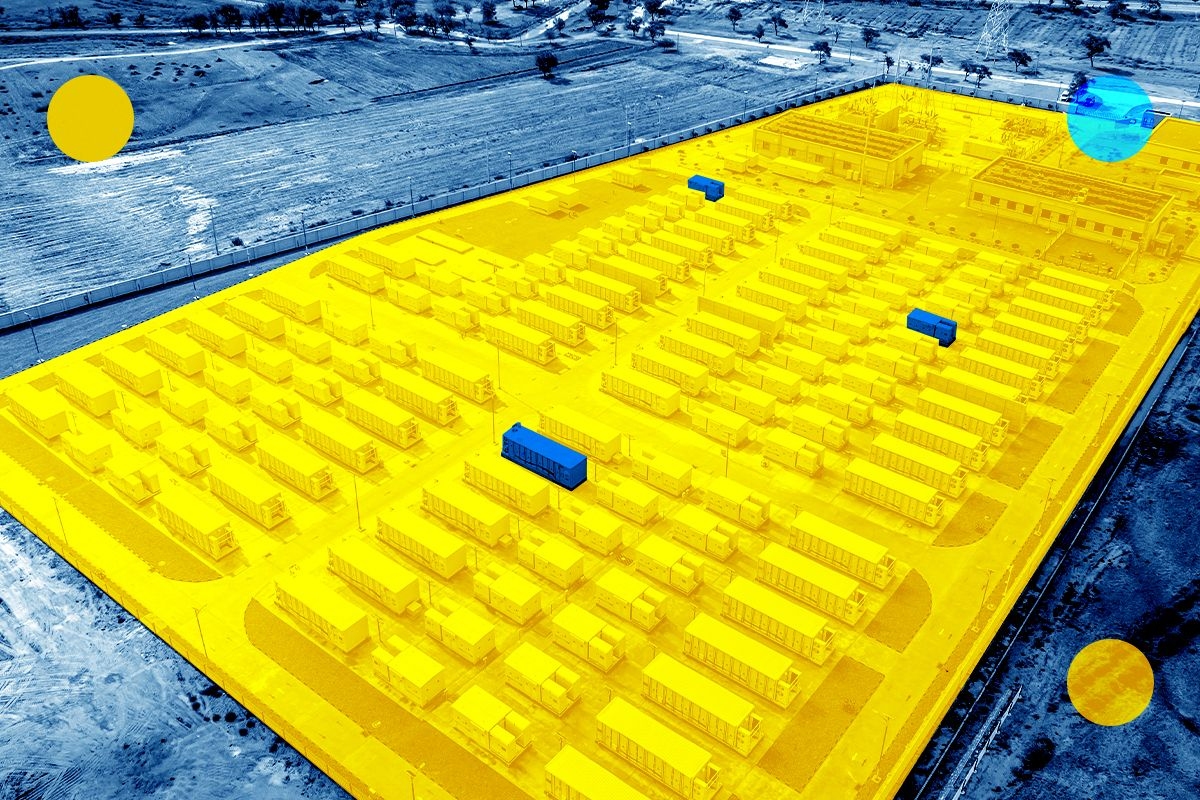

Batteries are the silent workhorses of our technological lives, powering our phones, computers, tablets, and remotes. But their impact goes far beyond our daily screentime — they’re also transforming the electricity grid itself. Grid-scale batteries store excess renewable energy and release it as needed, compensating for the fact that solar and wind resources aren’t always available on demand.

The price of the most ubiquitous battery technology — lithium-ion — has fallen remarkably in the past 15 years. That’s allowed for an enormous buildout of battery storage systems in the U.S. and beyond, which has in turn helped to integrate more renewables onto the grid than ever before. With the assistance of batteries, California ran entirely on clean energy for the equivalent of 51 days last year, while South Australia managed the same for 99 days.

Even as deployment accelerates, startups and other innovators are working to improve on standard lithium-ion tech — or in some cases, supplant it. We’ll get into all that soon, but first, let’s start with a little Battery 101.

All electrochemical batteries — that’s everything from your standard AA to grid-scale lithium-ion systems — work by turning chemical energy into electrical energy through what’s known as an electrochemical reaction. These batteries have three primary components:

Grid batteries charge when there’s excess renewable energy on the grid or when demand for energy is low. When a lithium-ion battery is charging, lithium ions move from the cathode to the anode, where they’re stored. When the battery discharges electricity back to the grid, lithium ions move from the anode to the cathode. This movement triggers the release of electrons at the anode, which move through an external wire that carries power to the grid.

There’s variation within the realm of lithium-ion batteries. For example, some use different cathode chemistries, a solid electrolyte, or a pure lithium metal anode. Within the broader world of electrochemical batteries, there are also a variety of alternate chemistries including sodium-ion, lithium-sulfur, and iron-air (more on those below).

But if one broadens the definition of a battery to include any system that stores energy, that’s when the possibilities really open up. In this sense, a battery could be a pumped hydropower storage system, in which energy is stored by moving water uphill into a reservoir and later releasing it to generate electricity through kinetic energy. A battery could also be energy stored as heat or compressed air. Many of these mechanisms rely on converting stored energy into electricity by turning a turbine or generator.

Batteries help to stabilize the electric grid and help communities and grid operators to take full advantage of their renewable energy resources by providing a reliable power supply when, as the saying goes, the sun isn’t shining and the wind isn’t blowing. New solar or wind plants combined with battery storage can also be highly cost-effective, achieving power prices that are competitive with or lower than those of new natural gas facilities in many cases.

Homes and businesses can also install their own personal battery storage systems to bank energy from rooftop solar panels or directly from the grid. This allows individuals and companies to lower their electricity bills by charging their batteries when grid prices are low and using stored energy when prices are high.

By the end of last year, the installed capacity of utility-scale batteries in the U.S. reached about 26 gigawatts, surpassing the cumulative capacity of pumped hydro for the first time. So while pumped hydro can still store a larger amount of total energy, batteries can now deliver more instantaneous power to the grid than any other energy storage resource. And though that 26 gigawatts represents a mere 2% of the U.S.’s total 1,230 gigawatts of generation capacity, the battery sector is growing rapidly. The International Energy Agency reported in February that planned capacity additions for this year totaled 18.2 gigawatts for the U.S. alone.

Lithium-ion batteries weren’t originally designed for grid-scale energy storage. Rather, they were commercialized in the early 1990s for use in portable consumer electronics such as camcorders, cell phones, and laptops. These batteries proved to be more energy dense, lighter, and longer lasting than their predecessors, and were thus eventually adopted for a whole host of applications, including the growing electric vehicle market in the 2010s.

As electric vehicle production ramped up throughout the decade, manufacturers scaled up their production of lithium-ion batteries, quickly driving down prices — from 2010 to 2020 the cost of battery packs declined nearly 90%. Production became primarily concentrated in East Asia, where companies such as CATL, LG Energy Solution, and Panasonic emerged as dominant players.

As the cheapest and most mature battery tech on the market, lithium-ion thus became the default for grid developers looking to manage the variability of intermittent solar and wind resources. As renewables deployment surged, adding battery storage to these facilities started to become more cost-effective than building new fossil-fuel facilities in some markets and provided a reliable way to regulate the grid’s frequency. Lithium-ion batteries can begin absorbing or delivering power at a moment’s notice, which is integral to keeping the grid balanced.

While lithium-ion batteries have never been a very practical or economical option when it comes to long-duration storage — that is, the ability to dispatch energy for more than about four to eight hours at a time — they are well suited to applications such as storing excess solar produced during the day for use in the evening, or smoothing out the fluctuations in renewable resources throughout the day.

For one, China essentially has a virtual monopoly on the lithium-ion battery industry. The country made EV production a national priority beginning in the 2000s, and by the 2010s it was heavily subsidizing battery and EV manufactures alike. Thus, China came to dominate the supply chain at nearly every level, from raw materials refining to cell manufacturing, anode and cathode production, and battery pack assembly. Ideally, the U.S. would lessen its technological reliance on a nation that it’s long seen as an adversary, but building a domestic lithium-ion battery industry from scratch is an extremely complex and expensive endeavor.

In terms of technical drawbacks, most lithium-ion batteries use a flammable liquid electrolyte. That’s prone to catching fire if a battery component or surrounding equipment fails, if a cell is punctured or simply overheats, as illustrated by the Moss Landing fire in California, which broke out in January at one the world’s largest battery storage facilities. While the energy density of lithium-ion is a main selling point, the flipside is that in a fire, more energy equals more heat. And since grid-scale systems pack battery cells close together, a fire in one cell can spread quickly across an entire facility.

Finally, in terms of cost, there’s only so far lithium-ion batteries can fall due to the expense of the raw materials. The price of lithium itself has been notoriously volatile. After hitting record highs in 2022, the commodity price subsequently collapsed after a wave of new mining projects oversupplied the market. This type of volatility wreaks havoc for battery storage developers and their balance sheets, thus spurring interest in chemistries that offer lower, more stable costs, as well as technologies with potentially superior cycle life, energy density, discharge times, and safety profiles.

The most widely commercialized spin on conventional lithium-ion batteries, which are traditionally made with an NMC cathode, is a variant known as lithium iron phosphate, or LFP. The iron-phosphate bond in a LFP cathode is very strong, making it more thermally stable than those in NMC batteries. LFP materials are also more structurally durable than nickel and cobalt, meaning these batteries can be charged and discharged more times before wearing out. Finally, LFPs are also cheaper and more sustainable, as the cathode materials are plentiful and less environmentally damaging to mine. LFP’s main drawback is its lower energy density, but its many advantages have enabled it to overtake NMC as the leading chemistry for new battery energy storage systems.

All the other competitors have much lower levels of commercial maturity. But on the plus side, this means there’s an opportunity to build out domestic supply chains for them. Sodium-ion batteries, for example, replace lithium with sodium, which is far more abundant. They’re also more thermally stable. Unfortunately for U.S. manufacturers, China is already surging ahead in the race to scale up this tech. Then there’s the more nascent lithium-sulfur batteries. They have a very high theoretical energy density, which could lead to lighter and more compact energy storage systems if companies can overcome core technical challenges such as short cycle life.

Flow batteries are also an option that’s been studied for decades. These store energy in liquid electrolytes held in external tanks rather than in solid electrodes. This presents a promising option for longer-duration energy storage since the design can be scaled easily — more energy simply means bigger tanks. Because the active materials are liquid, these batteries also have a very long cycle life, and their water-based designs are non-flammable. Flow batteries are also much bulkier, however, and haven’t yet scaled enough to become cost-competitive with lithium-ion under most circumstances.

Getting into the realm of long-duration storage also opens up possibilities such as iron-air batteries, which are being commercialized by the Massachusetts-based Form Energy. In theory, these can discharge for 100-plus hours by taking in oxygen from the air and reacting it with iron to form rust, releasing electrons in the process. When the battery is charging, an electrical current converts the rust back into iron. Because iron is cheap and plentiful, this tech could also be significantly less expensive than LFP batteries. And since it uses a water-based electrolyte, these batteries aren’t flammable. The first iron-air battery plant is set to come online at the end of the year.

Beyond the electrochemical domain, there’s a wider, weirder world of energy storage technologies, many of which are being explored for their long-duration storage potential. Pumped hydro can only be built only in very specific geographies, so it’s not a main competitor in many regions today. But gravity-based storage companies such as Energy Vault often take inspiration from this approach, storing energy by using excess electricity to raise heavy objects such as concrete blocks. When energy is needed, the blocks are lowered, causing the motors that lifted them to run in reverse and act as generators to produce electricity.

Canadian company Hydrostor is pursuing another method, which involves using surplus energy to compress air and pump it into a water-filled cavern, displacing the water to the surface. To discharge, water is released back into the cavern, pushing the air to the surface, where it mixes with stored heat to turn an electricity-generating turbine.

Then there’s thermal energy storage — essentially storing energy as heat in materials such as carbon blocks. This method has the potential to decarbonize industrial processes such as steel and cement production, which demand high temperatures that are difficult to achieve with electricity. Via resistance heating — the same technology as a toaster — electricity from renewable energy is converted into heat, which is then stored in thermally conductive rocks or bricks. When that heat is needed, it can be delivered directly as hot air or steam to the facility, or in some cases converted back into electricity for use at the facility or on the grid.

Experts say that none of the aforementioned technologies is likely to fully replace lithium-ion anytime soon. That’s in large part because lithium-ion is a fully mature technology with well-established supply chains, but also because it’s simply efficient and cost effective for what it can do.

Many of the technologies mentioned could, however, become effective complements to lithium-ion on the grid. For example, it’s possible that some combination of iron-air batteries, gravity energy storage, and compressed air energy storage could meet longer-duration needs — in some cases discharging continuously for days at a time. Thermal energy storage could also play a role here, as well as in decarbonizing high-heat heavy industries, which don’t make economic sense to electrify with lithium-ion batteries.

Sodium-ion batteries could eventually become cheaper than LFP, but because the tech has yet to scale and reach that price point, it’s still primarily viewed as a complementary solution. Having other viable battery chemistries such as sodium-ion would help reduce the overall demand for lithium, thus working to stabilize prices and risk in the battery supply chain as a whole. But because sodium-ion is less energy dense, it probably won’t make sense in space-constrained regions.

As for lithium-sulfur, the tech is just beginning to hit the market as companies such as Lyten focus on early applications in drones, satellites, and two- and three-wheelers. But it doesn’t yet have the cycle life to make sense for any grid-scale applications, and whether it will ever get there has yet to be discovered.

Yes, but battery recycling — especially for battery energy storage systems — is still a nascent industry. And it remains uncertain whether recycling and reusing battery materials is financially viable in an environment where lithium prices have plummeted and other key battery minerals such as nickel, cobalt, and graphite have become significantly cheaper. LFP’s cost efficiency improvements have further depressed interest in recycling their materials. But there’s still interest in this sector as it could help establish a domestic mineral supply chain, greatly reduce the need for environmentally disruptive mining projects, and ameliorate problems such as toxic chemical leaching and fire risk, which can occur when batteries are improperly disposed of.

Because grid-scale battery deployments didn’t begin to ramp in earnest until 2019, most systems have yet to reach the end of their useful life, which can last on the order of 10 to 20 years. As such, most leading battery recyclers — such as the well-funded startup Redwood Materials — are primarily focused on old EV batteries for now. Redwood says it can recover, on average, over 95% of battery materials such as lithium, nickel, cobalt, copper, aluminum, and graphite. Recently, the company has also been working to repurpose old EV batteries with some life left in them to make grid-scale battery storage systems, and it’s made forays into recycling grid batteries as well.

One of the industry’s former leaders, Li-Cycle, filed for bankruptcy in May, while another player, Ascend Elements, has paused construction on its recycling facility in Kentucky due to “changing market conditions.” As the U.S. seeks to develop a more localized battery supply chain, however, recycling will only become more critical.

It’s a mixed bag. On the one hand, President Trump’s steep tariffs on Chinese goods are set to substantially increase prices for domestic battery energy storage systems, given that the U.S. imports nearly all of its battery cells from China. This will threaten developers’ margins, potentially leading to project cancellations or delays.

Trump’s One Big Beautiful Bill maintained tax credits for battery energy storage projects through 2032, however stringent foreign sourcing rules now apply, withholding tax credits from projects that source a certain percentage of their components from Russia, Iran, North Korea, and most importantly, China. Given how China-centric the battery supply chain is, achieving the required sourcing levels could prove difficult, though exactly how difficult ultimately depends on forthcoming guidance from the Treasury department.

On the bright side, the administration is also bullish on bolstering the U.S. supply chain for critical minerals and rare earths. In a recent meeting, White House officials told a group of critical minerals firms that they would guarantee a price floor for their products. Such a policy could, of course, bolster the domestic battery supply chain, though at the risk of making this tech more expensive.

Assuming the U.S. navigates the current political headwinds and maintains a degree of momentum in its transition to clean energy, battery energy storage will play an increasingly critical role on the future grid, both domestically and globally. As electricity demand grows and renewables make up a progressively larger proportion of the mix, batteries will help ensure grid flexibility and resiliency. That will be increasingly important as extreme weather events become more common and severe.

In some markets, solar plus storage facilities have been more economical than so-called fossil fuel “peaker plants” for years. Peakers fire up during times of maximum electricity demand, and as batteries continue to fall in price, stored renewable power becomes an ever-cheaper way to supplement supply. As long-duration storage tech advances and comes down the cost curve, renewables will be able to provide firm baseload power over a period of days or even weeks, making fossil fuel infrastructure increasingly obsolete.

The International Energy Agency reports that in order to reach net zero emissions by 2050, global grid-scale battery storage needs to expand to nearly 970 gigawatts of capacity by 2030. That means annual grid-scale deployments must average about 120 gigawatts per year from 2023 to 2030. So while last year saw a record-setting 55 gigawatts of newly installed grid-scale capacity, that type of hockey-stick growth will need to accelerate even further if batteries are to pull their weight in the IEA’s net zero scenario.

Log in

To continue reading, log in to your account.

Create a Free Account

To unlock more free articles, please create a free account.

The proportion of voters who strongly oppose development grew by nearly 50%.

During his State of the Union address Tuesday night, President Donald Trump attempted to stanch the public’s bleeding support for building the data centers his administration says are necessary to beat China in the artificial intelligence race. With “many Americans” now “concerned that energy demand from AI data centers could unfairly drive up their electricity bills,” Trump said, he pledged to make major tech companies pay for new power plants to supply electricity to data centers.

New polling from energy intelligence platform Heatmap Pro shows just how dramatically and swiftly American voters are turning against data centers.

Earlier this month, the survey, conducted by Embold Research, reached out to 2,091 registered voters across the country, explaining that “data centers are facilities that house the servers that power the internet, apps, and artificial intelligence” and asking them, “Would you support or oppose a data center being built near where you live?” Just 28% said they would support or strongly support such a facility in their neighborhood, while 52% said they would oppose or strongly oppose it. That’s a net support of -24%.

When Heatmap Pro asked a national sample of voters the same question last fall, net support came out to +2%, with 44% in support and 42% opposed.

The steep drop highlights a phenomenon Heatmap’s Jael Holzman described last fall — that data centers are "swallowing American politics,” as she put it, uniting conservation-minded factions of the left with anti-renewables activists on the right in opposing a common enemy.

The results of this latest Heatmap Pro poll aren’t an outlier, either. Poll after poll shows surging public antipathy toward data centers as populists at both ends of the political spectrum stoke outrage over rising electricity prices and tech giants struggle to coalesce around a single explanation of their impacts on the grid.

“The hyperscalers have fumbled the comms game here,” Emmet Penney, an energy researcher and senior fellow at the right-leaning Foundation for American Innovation, told me.

A historian of the nuclear power sector, Penney sees parallels between the grassroots pushback to data centers and the 20th century movement to stymie construction of atomic power stations across the Western world. In both cases, opponents fixated on and popularized environmental criticisms that were ultimately deemed minor relative to the benefits of the technology — production of radioactive waste in the case of nuclear plants, and as seems increasingly clear, water usage in the case of data centers.

Likewise, opponents to nuclear power saw urgent efforts to build out the technology in the face of Cold War competition with the Soviet Union as more reason for skepticism about safety. Ditto the current rhetoric on China.

Penney said that both data centers and nuclear power stoke a “fear of bigness.”

“Data centers represent a loss of control over everyday life because artificial intelligence means change,” he said. “The same is true about nuclear,” which reached its peak of expansion right as electric appliances such as dishwashers and washing machines were revolutionizing domestic life in American households.

One of the more fascinating findings of the Heatmap Pro poll is a stark urban-rural divide within the Republican Party. Net support for data centers among GOP voters who live in suburbs or cities came out to -8%. Opposition among rural Republicans was twice as deep, at -20%. While rural Democrats and independents showed more skepticism of data centers than their urbanite fellow partisans, the gap was far smaller.

That could represent a challenge for the Trump administration.

“People in the city are used to a certain level of dynamism baked into their lives just by sheer population density,” Penney said. “If you’re in a rural place, any change stands out.”

Senator Bernie Sanders, the democratic socialist from Vermont, has championed legislation to place a temporary ban on new data centers. Such a move would not be without precedent; Ireland, transformed by tax-haven policies over the past two decades into a hub for Silicon Valley’s giants, only just ended its de facto three-year moratorium on hooking up data centers to the grid.

Senator Josh Hawley, the Missouri Republican firebrand, proposed his own bill that would force data centers off the grid by requiring the complexes to build their own power plants, much as Trump is now promoting.

On the opposite end of the spectrum, you have Republicans such as Mississippi Governor Tate Reeves, who on Tuesday compared halting construction of data centers to “civilizational suicide.”

“I am tempted to sit back and let other states fritter away the generational chance to build. To laugh at their short-sightedness,” he wrote in a post on X. “But the best path for all of us would be to see America dominate, because our foes are not like us. They don’t believe in order, except brutal order under their heels. They don’t believe in prosperity, except for that gained through fraud and plunder. They don’t think or act in a way I can respect as an American.”

Then you have the actual hyperscalers taking opposite tacks. Amazon Web Services, for example, is playing offense, promoting research that shows its data centers are not increasing electricity rates. Claude-maker Anthropic, meanwhile, issued a de facto mea culpa, pledging earlier this month to offset all its electricity use.

Amid that scattershot messaging, the critical rhetoric appears to be striking its targets. Whether Trump’s efforts to curb data centers’ impact on the grid or Reeves’ stirring call to patriotic sacrifice can reverse cratering support for the buildout remains to be seen. The clock is ticking. There are just 36 weeks until the midterm Election Day.

The public-private project aims to help realize the president’s goal of building 10 new reactors by 2030.

The Department of Energy and the Westinghouse Electric Company have begun meeting with utilities and nuclear developers as part of a new project aimed at spurring the country’s largest buildout of new nuclear power plants in more than 30 years, according to two people who have been briefed on the plans.

The discussions suggest that the Trump administration’s ambitious plans to build a fleet of new nuclear reactors are moving forward at least in part through the Energy Department. President Trump set a goal last year of placing 10 new reactors under construction nationwide by 2030.

The project aims to purchase the parts for 8 gigawatts to 10 gigawatts of new nuclear reactors, the people said. The reactors would almost certainly be AP1000s, a third-generation reactor produced by Westinghouse capable of producing up to 1.1 gigawatts of electricity per unit.

The AP1000 is the only third-generation reactor successfully deployed in the United States. Two AP1000 reactors were completed — and powered on — at Plant Vogtle in eastern Georgia earlier this decade. Fifteen other units are operating or under construction worldwide.

Representatives from Westinghouse and the Energy Department did not respond to requests for comment.

The project would use government and private financing to buy advanced reactor equipment that requires particularly long lead times, the people said. It would seek to lower the cost of the reactors by placing what would essentially be a single bulk order for some of their parts, allowing Westinghouse to invest in and scale its production efforts. It could also speed up construction timelines for the plants themselves.

The department is in talks with four to five potential partners, including utilities, independent power producers, and nuclear development companies, about joining the project. Under the plan, these utilities or developers would agree to purchase parts for two new reactors each. The program would be handled in part by the department’s in-house bank, the Loan Programs Office, which the Trump administration has dubbed the Office of Energy Dominance Financing.

This fleet-based approach to nuclear construction has succeeded in the past. After the oil crisis struck France in the 1970s, the national government responded by planning more than three-dozen reactors in roughly a decade, allowing the country to build them quickly and at low cost. France still has some of the world’s lowest-carbon electricity.

By comparison, the United States has built three new nuclear reactors, totaling roughly 3.5 gigawatts of capacity, since the year 2000, and it has not significantly expanded its nuclear fleet since 1990. The Trump administration set a goal in May to quadruple total nuclear energy production — which stands at roughly 100 gigawatts today — to more than 400 gigawatts by the middle of the century.

The Trump administration and congressional Republicans have periodically announced plans to expand the nuclear fleet over the past year, although details on its projects have been scant.

Senator Dave McCormick, a Republican of Pennsylvania, announced at an energy summit last July that Westinghouse was moving forward with plans to build 10 new reactors nationwide by 2030.

In October, Commerce Secretary Howard Lutnick announced a new deal between the U.S. government, the private equity firm Brookfield Asset Management, and the uranium company Cameco to deploy $80 billion in new Westinghouse reactors across the United States. (A Brookfield subsidiary and Cameco have jointly owned Westinghouse since it went bankrupt in 2017 due to construction cost overruns.) Reuters reported last month that this deal aimed to satisfy the Trump administration’s 2030 goal.

While there have been other Republican attempts to expand the nuclear fleet over the years, rising electricity demand and the boom in artificial intelligence data centers have brought new focus to the issue. This time, Democratic politicians have announced their own plans to boost nuclear power in their states.

In January, New York Governor Kathy Hochul set a goal of building 4 gigawatts of new nuclear power plants in the Empire State.

In his State of the State address, Governor JB Pritzker of Illinois told lawmakers last week that he hopes to see at least 2 gigawatts of new nuclear power capacity operating in his state by 2033.

Meeting Trump’s nuclear ambitions has been a source of contention between federal agencies. Politico reported on Thursday that the Energy Department had spent months negotiating a nuclear strategy with Westinghouse last year when Lutnick inserted himself directly into negotiations with the company. Soon after, the Commerce Department issued an announcement for the $80 billion megadeal, which was big on hype but short on details.

The announcement threw a wrench in the Energy Department’s plans, but the agency now seems to have returned to the table. According to Politico, it is now also “engaging” with GE Hitachi, another provider of advanced nuclear reactors.

On nuclear tax credits, BLM controversy, and a fusion maverick’s fundraise

Current conditions: A third storm could dust New York City and the surrounding area with more snow • Floods and landslides have killed at least 25 people in Brazil’s southeastern state of Minas Gerais • A heat dome in Western Europe is pushing up temperatures in parts of Portugal, Spain, and France as high as 15 degrees Celsius above average.

The Department of Energy’s in-house lender, the Loan Programs Office — dubbed the Office of Energy Dominance Financing by the Trump administration — just gave out the largest loan in its history to Southern Company. The nearly $27 billion loan will “build or upgrade over 16 gigawatts of firm reliable power,” including 5 gigawatts of new gas generation, 6 gigawatts of uprates and license renewals for six different reactors, and more than 1,300 miles of transmission and grid enhancement projects. In total, the package will “deliver $7 billion in electricity cost savings” to millions of ratepayers in Georgia and Alabama by reducing the utility giant’s interest expenses by over $300 million per year. “These loans will not only lower energy costs but also create thousands of jobs and increase grid reliability for the people of Georgia and Alabama,” Secretary of Energy Chris Wright said in a statement.

Over in Utah, meanwhile, the state government is seeking the authority to speed up its own deployment of nuclear reactors as electricity demand surges in the desert state. In a letter to the Nuclear Regulatory Commission dated November 10 — but which E&E News published this week — Tim Davis, the executive director of Utah’s Department of Environmental Quality, requested that the federal agency consider granting the state the power to oversee uranium enrichment, microreactor licensing, fuel storage, and reprocessing on its own. All of those sectors fall under the NRC’s exclusive purview. At least one program at the NRC grants states limited regulatory primacy for some low-level radiological material. While there’s no precedent for a transfer of power as significant as what Utah is requesting, the current administration is upending norms at the NRC more than any other government since the agency’s founding in 1975.

Building a new nuclear plant on a previously undeveloped site is already a steep challenge in electricity markets such as New York, California, or the Midwest, which broke up monopoly utilities in the 1990s and created competitive auctions that make decade-long, multibillion-dollar reactors all but impossible to finance. A growing chorus argues, as Heatmap’s Matthew Zeitlin wrote, that these markets “are no longer working.” Even in markets with vertically-integrated power companies, the federal tax credits meant to spur construction of new reactors would make financing a greenfield plant is just as impossible, despite federal tax credits meant to spur construction of new reactors. That’s the conclusion of a new analysis by a trio of government finance researchers at the Center for Public Enterprise. The investment tax credit, “large as it is, cannot easily provide them with upfront construction-period support,” the report found. “The ITC is essential to nuclear project economics, but monetizing it during construction poses distinct challenges for nuclear developers that do not arise for renewable energy projects. Absent a public agency’s ability to leverage access to the elective payment of tax credits, it is challenging to see a path forward for attracting sufficient risk capital for a new nuclear project under the current circumstances.”

Steve Pearce, Trump’s pick to lead the Department of the Interior’s Bureau of Land Management, wavered when asked about his record of pushing to sell off federal lands during his nomination hearing Wednesday. A former Republican lawmaker from New Mexico, Pearce has faced what the public lands news site Public Domain called “broad backlash from environmental, conservation, and hunting groups for his record of working to undermine public land protections and push land sales as a way to reduce the federal deficit.” Faced with questions from Democratic senators, Pearce said, “I’m not so sure that I’ve changed,” but insisted he didn’t “believe that we’re going to go out and wholesale land from the federal government.” That has, however, been the plan since the start of the administration. As Heatmap’s Jeva Lange wrote last year, Republicans looked poised to use their trifecta to sell off some of the approximately 640 million acres of land the federal government owns.

Sign up to receive Heatmap AM in your inbox every morning:

At Tuesday’s State of the Union address, as I told you yesterday, Trump vowed to force major data center companies to build, bring, or buy their own power plants to keep the artificial intelligence boom from driving up electricity prices. On Wednesday, Fox News reported that Amazon, Google, Meta, Microsoft, xAI, Oracle, and OpenAI planned to come to the White House to sign onto the deal. The meeting is set to take place sometime next month. Data centers are facing mounting backlash. Developers abandoned at least 25 data centers last year amid mounting pushback from local opponents, Heatmap's Robinson Meyer recently reported.

Shine Technologies is a rare fusion company that’s actually making money today. That’s because the Wisconsin-based firm uses its plasma beam fusion technology to produce isotopes for testing and medical therapies. Next, the company plans to start recycling nuclear waste for fresh reactor fuel. To get there, Shine Technologies has raised $240 million to fund its efforts for the next few years, as I reported this morning in an exclusive for Heatmap. Nearly 63% of the funding came from biotech billionaire Patrick Soon-Shiong, who will join the board. The capital will carry the company through the launch of the world’s largest medical isotope producer and lay the foundations of a new business recycling nuclear waste in the early 2030s that essentially just reorders its existing assembly line.

Vineyard Wind is nearly complete. As of Wednesday, 60 of the project’s 62 turbines have been installed off the coast of Massachusetts. Of those, E&E News reported, 52 have been cleared to start producing power. The developer Iberdrola said the final two turbines may be installed in the next few days. “For me, as an engineer, the farm is already completed,” Iberdrola’s executive chair, Ignacio Sánchez Galán, told analysts on an earnings call. “I think these numbers mean the level of availability is similar for other offshore wind farms we have in operation. So for me, that is completed.”