You’re out of free articles.

Log in

To continue reading, log in to your account.

Create a Free Account

To unlock more free articles, please create a free account.

Sign In or Create an Account.

By continuing, you agree to the Terms of Service and acknowledge our Privacy Policy

Welcome to Heatmap

Thank you for registering with Heatmap. Climate change is one of the greatest challenges of our lives, a force reshaping our economy, our politics, and our culture. We hope to be your trusted, friendly, and insightful guide to that transformation. Please enjoy your free articles. You can check your profile here .

subscribe to get Unlimited access

Offer for a Heatmap News Unlimited Access subscription; please note that your subscription will renew automatically unless you cancel prior to renewal. Cancellation takes effect at the end of your current billing period. We will let you know in advance of any price changes. Taxes may apply. Offer terms are subject to change.

Subscribe to get unlimited Access

Hey, you are out of free articles but you are only a few clicks away from full access. Subscribe below and take advantage of our introductory offer.

subscribe to get Unlimited access

Offer for a Heatmap News Unlimited Access subscription; please note that your subscription will renew automatically unless you cancel prior to renewal. Cancellation takes effect at the end of your current billing period. We will let you know in advance of any price changes. Taxes may apply. Offer terms are subject to change.

Create Your Account

Please Enter Your Password

Forgot your password?

Please enter the email address you use for your account so we can send you a link to reset your password:

Just don’t confuse them with SMRs.

When politicians tell the CEO of Radiant that they love small modular reactors, he groans inwardly and just keeps smiling.

Doug Bernauer’s Radiant is not trying to make SMRs. His company — a VC-backed startup currently in the pre-application phase with the Nuclear Regulatory Commission — is designing a portable nuclear microreactor, which is intended to replace diesel generators. The politicians don’t always know the difference, Bernauer told me.

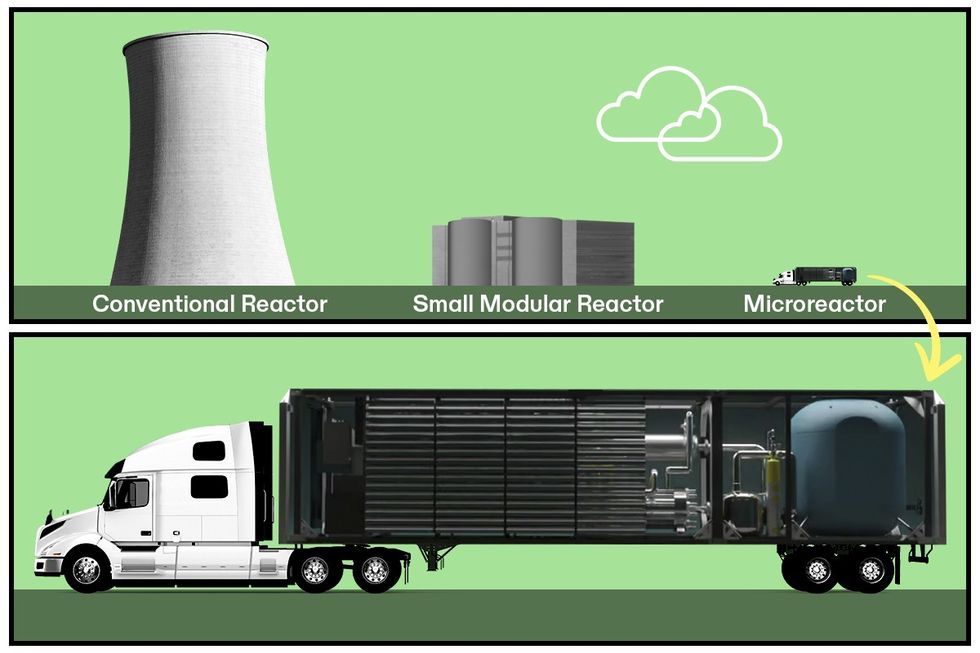

The SMR-microreactor confusion is common outside the world of nuclear. While they are both versions of advanced nuclear technologies not yet built in the United States (all of our nuclear power comes from big, old-fashioned plants), SMRs and microreactors have different designs, power outputs, costs, financing models, and potential use cases.

Unlike SMRs, microreactors are too small to ever become key energy players within a full-sized grid. But they could replace fossil fuels in some of the hardest to decarbonize sectors and locations in the world: mines, factories, towns in remote locations (especially Alaska and northern Canada), military bases, and (ironically) oil fields. For those customers, they could also make power supply and prices more consistent, secure, and dependable than fossil fuels, whose fluctuating prices batter industrial sectors and the residents of remote towns without discrimination.

Perhaps even more importantly, microreactors’ small size and comparatively low price could make them a gateway drug for new nuclear technologies in the U.S., helping companies and regulators build the know-how they need to lower the risk and cost for larger projects.

The big problem with this idea? No functional commercial nuclear microreactor actually exists. Industry experts cannot say with confidence that they know what the technological hurdles are going to be, how to solve them, or what it’s going to cost to address them.

“My crystal ball is broken,” John Parsons, an economist researching risk in energy at the Massachusetts Institute of Technology, said when I asked him whether he believed microreactors would make it through the technical gauntlet. “I’m hopeful. But I’m also very open-minded. I don’t know what’s going to happen. And I really believe we need a lot of shots on goal, and not all shots are going to go through,” he said.

Recent advances in both technology and regulation indicate that in the next few years, we should have some answers.

Private companies are expecting to conduct their first tests in about two years, and they are in conversations with potential customers. Radiant is hoping to test at the Idaho National Laboratory in 2026; Westinghouse and Ultra Safe Nuclear Corporation have contracts to test microreactors there as well. BWX Technologies is currently procuring the parts for a demonstration reactor through the Department of Defense’s prototype program — called Project Pele — and plans to test in about two years; X-energy signed an expanded contract in 2023 to build a prototype for Project Pele as well. Eielson Air Force Base in Alaska is commissioning a pilot microreactor. Schools including Pennsylvania State University and the University of Illinois have announced their interest as potential customers. Mining companies and other industry players in Alaska regularly express interest in embracing this technology.

The government is also quietly smoothing the way, removing barriers to make those tests possible. On March 4, the Nuclear Regulatory Commission released a new draft of licensing rules that will shape the future for these microreactors, and early March’s emergency spending bill included more than $2.5 billion repurposed for investment in a domestic supply chain of the type of nuclear fuel most advanced reactors will require.

“If we are truly committed as a nation to sticking to our climate goals, then we will absolutely get to a place where there are a bunch of microreactors replacing otherwise difficult to decarbonize sectors and applications,” said Kathryn Huff, the head of the office of nuclear energy at the Department of Energy.

Eric Gimon, a senior fellow at the nonprofit Energy Innovation, was a microreactor skeptic until about a month ago. His own recent research has made him far more optimistic that these microreactors might actually be technologically feasible, he told me when I reached out for an honest critique. “If they can make (the microreactors) work, it’s attractive,” he said. “There are a lot of industrial players that are going to want to buy them.”

“If your goal is to produce power at 4 cents per kilowatt hour, why would you buy any power that’s way more expensive than what you need? You do it because if that adds diversity to the portfolio and less variance, then you can get an overall portfolio that is lower cost or a lower risk for the same cost,” he told me.

Everyone I spoke to in the industry began our conversation with the same analogy: In the world of nuclear, full-size power plants are to airports what microreactors are to airplanes. Just as it's easier to build and regulate an airplane than an entire airport, in theory the microreactors should be built in a factory, regulated and licensed in the factory, and then rented out to or sold to the end user. An airport requires approvals specific to the construction site, a huge team of people employed for a long time to construct it and then another team to maintain it, and complicated financing based on the idea that the airport could be used for 50 or more years; a full-scale nuclear plant is the same. An airplane can basically be ordered online; a microreactor should be the same.

“They are sized to be similar to that kind of scope, where you could really consolidate a lot of the chemical and manufacturing oversight to a single location rather than moving thousands of people to a construction site,” Huff told me.

Microreactors should produce relatively small amounts of power (a maximum of 10-20 megawatts) and lots of heat with a tiny amount of nuclear fuel. They are usually portable, and if they aren’t portable they require a limited amount of construction or installation. Because it should not be possible to handle the fuel once it leaves the factory (most of the proposed reactor designs set the fuel deep into a dense, inaccessible matrix), these reactors wouldn’t require the same safety and security measures on site as a nuclear power plant. They’re easily operated or managed by people without nuclear expertise, and their safety design — called passive safety — should make it technically impossible for a reactor to meltdown.

“The excess reactivity is so small that you actually can’t get the reactor hot enough that you could start damaging the fuel. That’s something unique about the microreactor that would not necessarily be true for other types of nuclear,” Jeff Waksman, the program manager for the Department of Defense’s Strategic Capabilities Office, told me.

Microreactors should also cost on the order of tens of millions of dollars, not hundreds. That’s low enough that a company, university, town, or other similarly-sized entity could buy one or more of them. Because they’re cheaper than traditional nuclear, they don’t require lenders to take big risks on money committed over a very long period of time. If a mining company wanted to replace a diesel generator with one of these, they should be able to finance it in exactly the same way (a loan from the bank, for example). This makes their financial logic quite different from SMRs, which can suffer from some of the same problems as full-size nuclear power plants (see: NuScale’s recent setbacks).

“All of the things that contribute to a faster innovation cycle are true for microreactors compared to larger reactors. So you can just — build one,” said Rachel Slaybaugh, a partner at DCVC and a board member at Radiant, Fervo Energy, and Fourth Power.

Because microreactors max out at around 20 megawatts of energy, the economies of scale that eventually bring down energy prices for full-scale nuclear power can’t be replicated. While Jigar Shah, the director of the loan programs office at the DOE, speculated in a recent interview that costs might eventually go just below 10 cents per kilowatt hour, Parsons is skeptical that anyone could provide a practical cost estimate. It’s absolutely going to cost more than either large reactors or SMRs, Parsons said.

But cost comparisons to other types of nuclear technology aren’t practical, according to Slaybaugh. “You are going to be able to command a cost parity with diesel generators. It’s easy to get to a point where they make financial sense,” she said. “You can see why someone would pick one: This is not making noise, it’s not making local air pollution, you don’t have to deal with the diesel logistics complexity. You sell it at price parity, and maybe the first few customers pay a premium because they are excited about it.”

That premium price for the initial technology is the largest hurdle raised by every single person I spoke with, from the DOE to analysts and researchers to the different microreactor companies.

But there is one customer already inclined to pay a substantial premium: the Department of Defense. The U.S. military has greater resiliency and security needs than other consumers when it comes to its power supply, making the cost of microreactors more palatable. (And it doesn’t hurt that the taxpayer already foots the bill for enormous defense contracts, including for aircraft carriers and submarines powered by nuclear reactors). It’s common for technological innovations (think the internet, GPS, advanced prosthetics) to begin with the military and then expand outward to the consumer. Project Pele and the requests for proposals at Eielson Air Force Base both indicate that the pathway might be one for microreactors, according to Parsons.

For the president of BWXT Advanced Technologies, the Department of Defense’s decision to commission his company’s microreactor for Project Pele removed his last doubts that these microreactors would eventually be built. “The DOD being the first mover has extreme advantage for the country, and for eventually the commercial industry,” Joseph Miller told me. “The first mover was the barrier, and now it’s just 1,000 things that we’re working on all day every day to make it real, and there’s no gotcha out there that I see. That wasn’t the case when we were doing the design work, but now we’re making procurements to be able to assemble and deliver the reactor.”

Regardless of whether Miller’s optimism is well-founded, the experience gained in trying to make them happen is invaluable for a nuclear industry that’s been stuck in the mud for far too long.

“I've been talking with the federal government about the fact that there’s broader value in terms of getting wins on the board for the nuclear sector and getting the industry more experienced with building new things in a way that isn't quite so complicated,” Slaybaugh said. “Let’s have them build a thing that’s small and kind of cheap, and then they can go build a bigger thing that’s a little more expensive and a little more complicated. Let’s get some real reps in with microreactors.”

Log in

To continue reading, log in to your account.

Create a Free Account

To unlock more free articles, please create a free account.

The attacks on Iran have not redounded to renewables’ benefit. Here are three reasons why.

The fragility of the global fossil fuel complex has been put on full display. The Strait of Hormuz has been effectively closed, causing a shock to oil and natural gas prices, putting fuel supplies from Incheon to Karachi at risk. American drivers are already paying more at the pump, despite the United States’s much-vaunted energy independence. Never has the case for a transition to renewable energy been more urgent, clear, and necessary.

So despite the stock market overall being down, clean energy companies’ shares are soaring, right?

Wrong.

First Solar: down over 1% on the day. Enphase: down over 3%. Sunrun: down almost 8%; Tesla: down around 2.5%.

Why the slump? There are a few big reasons:

Several analysts described the market action today as “risk-off,” where traders sell almost anything to raise cash. Even safe haven assets like U.S. Treasuries sold off earlier today while the U.S. dollar strengthened.

“A lot of things that worked well recently, they’re taking a big beating,” Gautam Jain, a senior research scholar at the Columbia University Center on Global Energy Policy, told me. “It’s mostly risk aversion.”

Several trackers of clean energy stocks, including the S&P Global Clean Energy Transition Index (down 3% today) or the iShares Global Clean Energy ETF (down over 3%) have actually outperformed the broader market so far this year, making them potentially attractive to sell off for cash.

And some clean energy stocks are just volatile and tend to magnify broader market movements. The iShares Global Clean Energy ETF has a beta — a measure of how a stock’s movements compare with the overall market — higher than 1, which means it has tended to move more than the market up or down.

Then there’s the actual news. After President Trump announced Tuesday afternoon that the United States Development Finance Corporation would be insuring maritime trade “for a very reasonable price,” and that “if necessary” the U.S. would escort ships through the Strait of Hormuz, the overall market picked up slightly and oil prices dropped.

It’s often said that what makes renewables so special is that they don’t rely on fuel. The sun or the wind can’t be trapped in a Middle Eastern strait because insurers refuse to cover the boats it arrives on.

But what renewables do need is cash. The overwhelming share of the lifetime expense of a renewable project is upfront capital expenditure, not ongoing operational expenditures like fuel. This makes renewables very sensitive to interest rates because they rely on borrowed money to get built. If snarled supply chains translate to higher inflation, that could send interest rates higher, or at the very least delay expected interest rate cuts from central banks.

Sustained inflation due to high energy prices “likely pushes interest rate cuts out,” Jain told me, which means higher costs for renewables projects.

While in the long run it may make sense to respond to an oil or natural gas supply shock by diversifying your energy supply into renewables, political leaders often opt to try to maintain stability, even if it’s very expensive.

“The moment you start thinking about energy security, renewables jump up as a priority,” Jain said. “Most countries realize how important it is to be independent of the global supply chain. In the long term it works in favor of renewables. The problem is the short term.”

In the short term, governments often try to mitigate spiking fuel prices by subsidizing fossil fuels and locking in supply contracts to reinforce their countries’ energy supplies. Renewables may thereby lose out on investment that might more logically flow their way.

The other issue is that the same fractured supply chain that drives up oil and gas prices also affects renewables, which are still often dependent on imports for components. “Freight costs go up,” Jain said. “That impacts clean energy industry more.”

As for the Strait of Hormuz, Trump said the Navy would start escorting ships “as soon as possible.”

“It is difficult to imagine more arbitrary and capricious decisionmaking than that at issue here.”

A federal court shot down President Trump’s attempt to kill New York City’s congestion pricing program on Tuesday, allowing the city’s $9 toll on cars entering downtown Manhattan during peak hours to remain in effect.

Judge Lewis Liman of the U.S. District Court for the Southern District of New York ruled that the Trump administration’s termination of the program was illegal, writing, “It is difficult to imagine more arbitrary and capricious decisionmaking than that at issue here.”

So concludes a fight that began almost exactly one year ago, just after Trump returned to the White House. On February 19, 2025, the newly minted Transportation Secretary Sean Duffy sent a letter to Kathy Hochul, the governor of New York, rescinding the federal government’s approval of the congestion pricing fee. President Trump had expressed concerns about the program, Duffy said, leading his department to review its agreement with the state and determine that the program did not adhere to the federal statute under which it was approved.

Duffy argued that the city was not allowed to cordon off part of the city and not provide any toll-free options for drivers to enter it. He also asserted that the program had to be designed solely to relieve congestion — and that New York’s explicit secondary goal of raising money to improve public transit was a violation.

Trump, meanwhile, likened himself to a monarch who had risen to power just in time to rescue New Yorkers from tyranny. That same day, the White House posted an image to social media of Trump standing in front of the New York City skyline donning a gold crown, with the caption, "CONGESTION PRICING IS DEAD. Manhattan, and all of New York, is SAVED. LONG LIVE THE KING!"

New York had only just launched the tolling program a month earlier after nearly 20 years of deliberation — or, as reporter and Hell Gate cofounder Christopher Robbins put it in his account of those years for Heatmap, “procrastination.” The program was supposed to go into effect months earlier before, at the last minute, Hochul tried to delay the program indefinitely, claiming it was too much of a burden on New Yorkers’ wallets. She ultimately allowed congestion pricing to proceed with the fee reduced from $15 during peak hours to $9, and thereafter became one of its champions. The state immediately challenged Duffy’s termination order in court and defied the agency’s instruction to shut down the program, keeping the toll in place for the entirety of the court case.

In May, Judge Liman issued a preliminary injunction prohibiting the DOT from terminating the agreement, noting that New York was likely to succeed in demonstrating that Duffy had exceeded his authority in rescinding it.

After the first full year the program was operating, the state reported 27 million fewer vehicles entering lower Manhattan and a 7% boost to transit ridership. Bus speeds were also up, traffic noise complaints were down, and the program raised $550 million in net revenue.

The final court order issued Tuesday rejected Duffy’s initial arguments for terminating the program, as well as additional justifications he supplied later in the case.

“We disagree with the court’s ruling,” a spokesperson for the Transportation Department told me, adding that congestion pricing imposes a “massive tax on every New Yorker” and has “made federally funded roads inaccessible to commuters without providing a toll-free alternative.” The Department is “reviewing all legal options — including an appeal — with the Justice Department,” they said.

Current conditions: A cluster of thunderstorms is moving northeast across the middle of the United States, from San Antonio to Cincinnati • Thailand’s disaster agency has put 62 provinces, including Bangkok, on alert for severe summer storms through the end of the week • The American Samoan capital of Pago Pago is in the midst of days of intense thunderstorms.

We are only four days into the bombing campaign the United States and Israel began Saturday in a bid to topple the Islamic Republic’s regime. Oil prices closed Monday nearly 9% higher than where trading started last Friday. Natural gas prices, meanwhile, spiked by 5% in the U.S. and 45% in Europe after Qatar announced a halt to shipments of liquified natural gas through the Strait of Hormuz, which tapers at its narrowest point to just 20 miles between the shores of Iran and the United Arab Emirates. It’s a sign that the war “isn’t just an oil story,” Heatmap’s Matthew Zeitlin wrote yesterday. Like any good tale, it has some irony: “The one U.S. natural gas export project scheduled to start up soon is, of all things, a QatarEnergy-ExxonMobil joint venture.” Heatmap’s Robinson Meyer further explored the LNG angle with Eurasia Group analyst Gregory Brew on the latest episode of Shift Key.

At least for now, the bombing of Iranian nuclear enrichment sites hasn’t led to any detectable increase in radiation levels in countries bordering Iran, the International Atomic Energy Agency said Monday. That includes the Bushehr nuclear power plant, the Tehran research reactor, and other facilities. “So far, no elevation of radiation levels above the usual background levels has been detected in countries bordering Iran,” Director General Rafael Grossi said in a statement.

Financial giants are once again buying a utility in a bet on electricity growth. A consortium led by BlackRock subsidiary Global Infrastructure Partners and Swedish private equity heavyweight EQT announced a deal Monday to buy utility giant AES Corp. The acquisition was valued at more than $33 billion and is expected to close by early next year at the latest. “AES is a leader in competitive generation,” Bayo Ogunlesi, the chief executive officer of BlackRock’s Global Infrastructure Partners, said in a statement. “At a time in which there is a need for significant investments in new capacity in electricity generation, transmission, and distribution, especially in the United States of America, we look forward to utilizing GIP’s experience in energy infrastructure investing, as well as our operational capabilities to help accelerate AES’ commitment to serve the market needs for affordable, safe and reliable power.” The move comes almost exactly a year after the infrastructure divisions at Blackstone, the world’s largest alternative asset manager, bought the Albuquerque-based utility TXNM Energy in an $11.5 billion gamble on surging power demand.

China’s output of solar power surpassed that of wind for the first time last year as cheap panels flooded the market at home and abroad. The country produced nearly 1.2 million gigawatt-hours of electricity from solar power in 2025, up 40% from a year earlier, according to a Bloomberg analysis of National Bureau of Statistics data published Saturday. Wind generation increased just 13% to more than 1.1 gigawatt-hours. The solar boom comes as Beijing bolsters spending on green industry across the board. China went from spending virtually nothing on fusion energy development to investing more in one year than the entire rest of the world combined, as I have previously reported. To some, China is — despite its continued heavy use of coal — a climate hero, as Heatmap’s Katie Brigham has written.

Sign up to receive Heatmap AM in your inbox every morning:

Canada and India have a longstanding special friendship on nuclear power. Both countries — two of the juggernauts of the 56-country Commonwealth of Nations — operate fleets that rely heavily on pressurized heavy water reactors, a very different design than the light water reactors that make up the vast majority of the fleets in Europe and the United States. Ottawa helped New Delhi build its first nuclear plants. Now the two countries have renewed their atomic ties in what the BBC called a “landmark” deal Monday. As part of the pact, India signed a nine-year agreement with Canada’s largest uranium miner, Cameco, to supply fuel to New Delhi’s growing fleet of seven nuclear plants. The $1.9 billion deal opens a new market for Canada’s expanding production of uranium ore and gives India, which has long worried about its lack of domestic deposits, a stable supply of fuel.

India, meanwhile, is charging ahead with two new reactors at the Kaiga atomic power station in the southwestern state of Karnataka. The units are set to be IPHWR-700, natively designed pressurized heavy water reactors. Last week, the Nuclear Power Corporation of India poured the first concrete on the new pair of reactors, NucNet reported Monday.

The Spanish refiner Moeve has decided to move forward with an investment into building what Hydrogen Insight called “a scaled-back version” of the first phase of its giant 2-gigawatt Andalusian Green Hydrogen Valley project. Even in a less ambitious form, Reuters pegged the total value of the project at $1.2 billion. Meanwhile in the U.S., as I wrote yesterday, is losing major projects right as big production facilities planned before Trump returned to office come online.

Speaking of building, the LEGO Group is investing another $2.8 million into carbon dioxide removal. The Danish toymaker had already pumped money into carbon-removal projects overseen by Climate Impact Partners and ClimeFi. At this point, LEGO has committed $8.5 million to sucking planet-heating carbon out of the atmosphere, where it circulates for centuries. “As the program expands, it is helping to strengthen our understanding of different approaches and inform future decision-making on how carbon removal may complement our wider climate goals,” Annette Stube, LEGO’s chief sustainability officer, told Carbon Herald.